INTRODUCTION

Your product has EMC requirements. You have to test it to demonstrate compliance with those requirements. How do you prepare for the test? How do you prepare your product for the test? These are two different areas that need preparation before you go to the lab. Let’s look at them, one at a time.

HOW DO YOU PREPARE FOR THE TEST?

First, you need to understand what you need to gather before going to the lab. A step before that is that you must select a lab to perform the tests. Then, you need to know what information the lab will need prior to the tests in order to allow them to properly test your product and write a test report. Some labs0 may require a written test plan before performing the tests, and the contents of the test plan will aid them by gathering information needed for the test reports.

How do you select a lab? First, you need to know what will be required of the laboratory in order for its results to be acceptable in the countries in which you wish to sell your product. Not all labs are acceptable everywhere in the world. The requirements for a lab to be accepted in various parts of the world are beyond the scope of this article, but you should ensure that the lab’s results and reports will be acceptable. Some parts of the world have no restrictions on what lab you may use, others may require that the lab be accredited for testing in their country. When in doubt, ask to see proof.

Secondly, mere possession of accreditation is not, in and of itself, evidence that the lab truly does quality work. You should become educated on the requirements around the world and perform your own inspections of the candidate laboratories. Some labs will welcome your visit, others might not. You will have to decide what level of comfort is adequate for your company. If you don’t have the expertise in-house you might consider hiring a consultant to evaluate the laboratory or laboratories you are considering.

Once you have settled on a laboratory to perform the tests, find out from the lab what information they need you to provide. Later we’ll talk about the information that a laboratory must include in the test report, and you will see that much of it comes from you. Know what information is needed and have it available when you go to the lab. Part of you laboratory selection process should include asking about lead time requirements. Are they so busy that they can’t fit in the number of days you will need for the tests until 6 months from now? And you need to ship in 1 month? That is important information. Few things upset management more than being told that they can’t start shipping product (and receiving money) until a few months after they had planned. Your fault or not, you will be blamed, so make sure you understand your company’s schedule requirements and what the laboratory can deliver.

Also, talk to the lab and have a good idea how long the tests will take and then when they can deliver a test report for your review. Talk to your marketing people to see when they plan on announcing this product and start shipping it. You don’t want to be the bottleneck that stops the process. Have these discussions early (both with the lab and with your own people) and keep the information up to date. Ensure that you keep your management informed of the status and any delays that you see coming.

HOW DO YOU PREPARE THE PRODUCT FOR THE TEST?

First, design the product with EMC in mind. Provide guidance to the development team early and often on design features that they should include to increase their chances of passing the first time. Review the designs to make sure that obvious mistakes are not included in the product design. Perform preliminary development tests when possible to catch mistakes and failures early, when they can more easily be fixed.

Once the product is designed and debugged, make sure that all necessary hardware and software is available for the test. The hardware that you will need to provide to the laboratory may be more than just the box you are testing. What about peripheral devices? Are they common items that the laboratory might already have in their possession? Or are they special items that only you might have? You might also ensure that all subassemblies are installed correctly and that all chassis and enclosure fasteners are tight. What about the cables connecting the various parts of the system? Are specially designed cables necessary?

A classic example to consider is if your product includes an HDMI interface. If your product depends on properly shielded cables, with the shields properly terminated, cables that simply meet the HDMI cable specification may not be adequate. The HDMI specification does not address the termination of the outer shield of the cable and many HDMI compliant cables do not have this outer shield terminated or terminated properly. They meet the HDMI specification, but are not typically adequate from an EMC perspective. Does your product need the shield terminated? Make sure the cables used for the test (and sold with your product) have the shields terminated correctly.

If any software is required in order for your product to be exercised as required by the EMC standard to which it is being tested make sure you pack that software with the product, or pre-install it and test it to make sure it works. Remember that the clock is running when you arrive at the lab and you don’t want to be paying their hourly rate to troubleshoot you product to make it work, or waste time running back to your company to get software you forgot.

Also, it’s wise to bring the following items: product documentation, installation manual, user manual, extra tools – especially specialized ones required to remove covers or cables, etc., backup copies of software, a backup laptop, backup hardware in case of product failure (especially important for potentially destructive tests like ESD), extra cables, troubleshooting items like ferrite chokes, copper tape, and aluminum foil.

WHAT INFORMATION MIGHT YOU NEED TO PROVIDE TO THE LAB?

The laboratory is going to write a test report (or reports) for you at the completion of the tests (assuming the product passed, writing a full report for a product that fails is a waste of time and your money). ISO/IEC Guide 17025:2005 provides a list of items that must be included in the test report and regulatory agencies add their own requirements. Let’s look at the items that ISO/IEC 17025 requires:

Articles 5.10.2 and 5.10.3 of ISO/IEC 17025 list a number of required items to be included. These are;

•5.10.2a – The report is labeled with a title, such as “Test Report”

•5.10.2b – The name and address of the laboratory used for the measurement

• 5.10.2c – Unique identifier of the report on each page and a clear identification of the end of the report

• 5.10.2d – Name and address of the client

• 5.10.2e – Test methods clearly identified

• 5.10.2f –

-Description of the condition of the EUT

-Clear and unambiguous identification of the EUT on the cover or first page of the report. All applicable model numbers and manufacturer’s trade names are to be listed here

• 5.10.2g – Date(s) of the test shall be identified

• 5.10.2h – reference to the sampling plan and procedures used by the lab (not typically needed in an EMC test report)

• 5.10.2i – test results with units of measurement

• 5.10.2j – name(s), function(s) and signature(s) of per- son(s) authorizing the test report

• 5.10.2k – a statement to the effect that the results re- late only to the items tested

• 5.10.2 Note 1 – hard copies of test reports should include the page number and total number of pages

• 5.10.2 Note 2 – a statement that the test report shall not be reproduced except in full, without written approval of the lab.

• 5.10.3.1a – deviations from, additions to, or exclusions from the test methods, and information on specific test conditions, such as environmental conditions

-Temperature, humidity, barometric pressure

-Operating voltage and frequency

• 5.10.3.1b – a statement of compliance/non-compliance with requirements and/or specifications

• 5.10.3.1c – a statement on the estimated uncertainty of measurement

• 5.10.3.1d – where appropriate and needed, opinions and interpretations

• 5.10.3.1e – additional information which may be required by specific methods, customers or groups of customers

In the United States, the Federal Communications Commission (FCC) has some additional requirements. These will vary depending on the type of approval process used for the product

DEVICES AUTHORIZED UNDER VERIFICATION

•47 CFR 2.955(a)(3)

i. Indicate the actual date all testing was performed (see also 17025 5.10.2g)

ii. State the name of the test laboratory, company, or individual performing the verification testing. (see also 17025 5.10.2b)

iii. Contain a description of how the device was actually tested, identifying the measurement procedure and test equipment that was used (see also 17025 5.10.2e)

iv. Contain a description of the equipment under test (EUT) and support equipment connected to, or in- stalled within, the EUT (see also 17025 5.10.2f)

v. Identify the EUT and support equipment by trade name and model number and, if appropriate, by FCC Identifier and serial number

vi. Indicate the types and lengths of connecting cables used and how they were arranged or moved during testing

vii. Contain at least two drawings or photographs showing the test set-up for the highest line con- ducted emission and showing the test set-up for the highest radiated emission. These drawings or photographs must show enough detail to confirm other information contained in the test report. Any photographs used must be focused originals with- out glare or dark spots and must clearly show the test configuration used

viii. List all modifications, if any, made to the EUT by the testing company or individual to achieve compliance with the regulations in this chapter

ix. Include all of the data required to show compliance with the appropriate regulations in this chapter (see also 17025 5.10.2i)

x. Contain, on the test report, the signature of the individual responsible for testing the product along with the name and signature of an official of the responsible party, as designated in §2.909

DEVICES AUTHORIZED UNDER CERTIFICATION

• 47 CFR 2.1033(b)

i. The full name and mailing address of the manufacturer of the device and the applicant for certification (see also 17025 5.10.2d)

ii.FCC identifier

iii. A copy of the installation and operating instructions to be furnished the user. A draft copy of the instructions may be submitted if the actual document is not available. The actual document shall be furnished to the FCC when it becomes available

iv. A brief description of the circuit functions of the device along with a statement describing how the device operates. This statement should contain a description of the ground system and antenna, if any, used with the device

v. A block diagram showing the frequency of all oscillators in the device. The signal path and frequency shall be indicated at each block. The tuning range(s) and intermediate frequency shall be indicated at each block. A schematic diagram is also required for intentional radiators

vi. A report of measurements showing compliance with the pertinent FCC technical requirements. This report shall identify the test procedure used (e.g., specify the FCC test procedure, or industry test procedure that was used), the date the measurements were made, the location where the measurements were made, and the device that was tested (model and serial number, if available). The report shall include sample calculations show- ing how the measurement results were converted for comparison with the technical requirements

vii. A sufficient number of photographs to clearly show the exterior appearance, the construction, the component placement on the chassis, and the chassis assembly. The exterior views shall show the over- all appearance, the antenna used with the device (if any), the controls available to the user, and the required identification label in sufficient detail so that the name and FCC identifier can be read. In lieu of a photograph of the label, a sample label (or facsimile thereof) may be submitted together with a sketch showing where this label will be placed on the equipment. Photographs shall be of size A4 (21 cmx29.7cm)or8x10inches(20.3cmx25.4 cm). Smaller photographs may be submitted pro- vided they are sharp and clear, show the necessary detail, and are mounted on A4 (21 cm x 29.7 cm) or 8.5 x 11 inch (21.6 cm x 27.9 cm) paper. A sample label or facsimile together with the sketch showing the placement of this label shall be on the same size paper

viii. If the equipment for which certification is being sought must be tested with peripheral or accesso- ry devices connected or installed, a brief descrip- tion of those peripherals or accessories. The pe- ripheral or accessory devices shall be unmodified, commercially available equipment

DEVICES AUTHORIZED UNDER DECLARATION OF CONFORMITY

• 47 CFR 2.1075(a)(3)

i. The actual date or dates testing was performed

ii. The name of the test laboratory, company, or individual performing the testing. The Commission may request additional information regarding the test site, the test equipment or the qualifications of the company or individual performing the tests

iii. A description of how the device was actually test- ed, identifying the measurement procedure and test equipment that was used

iv. A description of the equipment under test (EUT) and support equipment connected to, or installed within, the EUT

v. The identification of the EUT and support equipment by trade name and model number and, if appropriate, by FCC Identifier and serial number

vi. The types and lengths of connecting cables used and how they were arranged or moved during testing

vii. At least two photographs showing the test set-up for the highest line conducted emission and showing the test set-up for the highest radiated emission. These photographs must be focused originals which show enough detail to confirm other information contained in the test report

viii. A description of any modifications made to the EUT by the testing company or individual to achieve compliance with the regulations

ix. All of the data required to show compliance with the appropriate regulations

x. The signature of the individual responsible for test- ing the product along with the name and signature of an official of the responsible party, as designated in §2.909

xi. A copy of the compliance information, as described in §2.1077, required to be provided with the equipment

In Taiwan, the Bureau of Standards, Metrology and Inspection (BSMI) has a few of their own requirements for report content.

•If testing with different numbers of cables connected to multiple samples of a given I/O port type is performed, data for each number of cables used shall be provided to show that the addition of the final cable did not in- crease emissions by more than 2 dB.

•A statement that the final test results represent the worst case, along with a listing of the configuration variations that were investigated to determine the worst case.

•Clear photographs of the test setup providing sufficient detail to duplicate the test results. Each test setup must be documented.

-6 exterior pictures of a system EUT for class A equipment

-6 exterior and 6 interior pictures of a system EUT for class B equipment.

-Pictures required for the power supply and internal boards. Board photos required of both sides with sufficient detail to identify EMC critical parts.

-Minimum photo size is 4 by 6 inches

•List of removable EMI suppression components in the product.

•List of key EMI generation components (clock generators and distribution parts)

•Block diagram of the EUT showing the clock distribution

•BSMI cover sheet containing the following information:

-Product Name. This shall be the same name as provided on shipping and final sales packaging

-Applicant (Intel for our products)

-Description of nameplate mains characteristics

-Logo or Brand

– Model Number or Type. Detailed model number(s) ◦ Test Result. Passed. State class A or class B

-Original Signature. Electronic signatures are acceptable if the report and all supporting documentation is submitted on a CD-ROM

The following items may be specific to one regulator, but should be provided in the report:

• List of accreditations, approvals, listings, etc held by the laboratory. Include identification numbers if applicable. • If multiple model numbers are covered by the report, provide a description and evidence of differences re- viewed by the laboratory.

• Name and signature of the person taking the data. Needed for each set of data in the report.

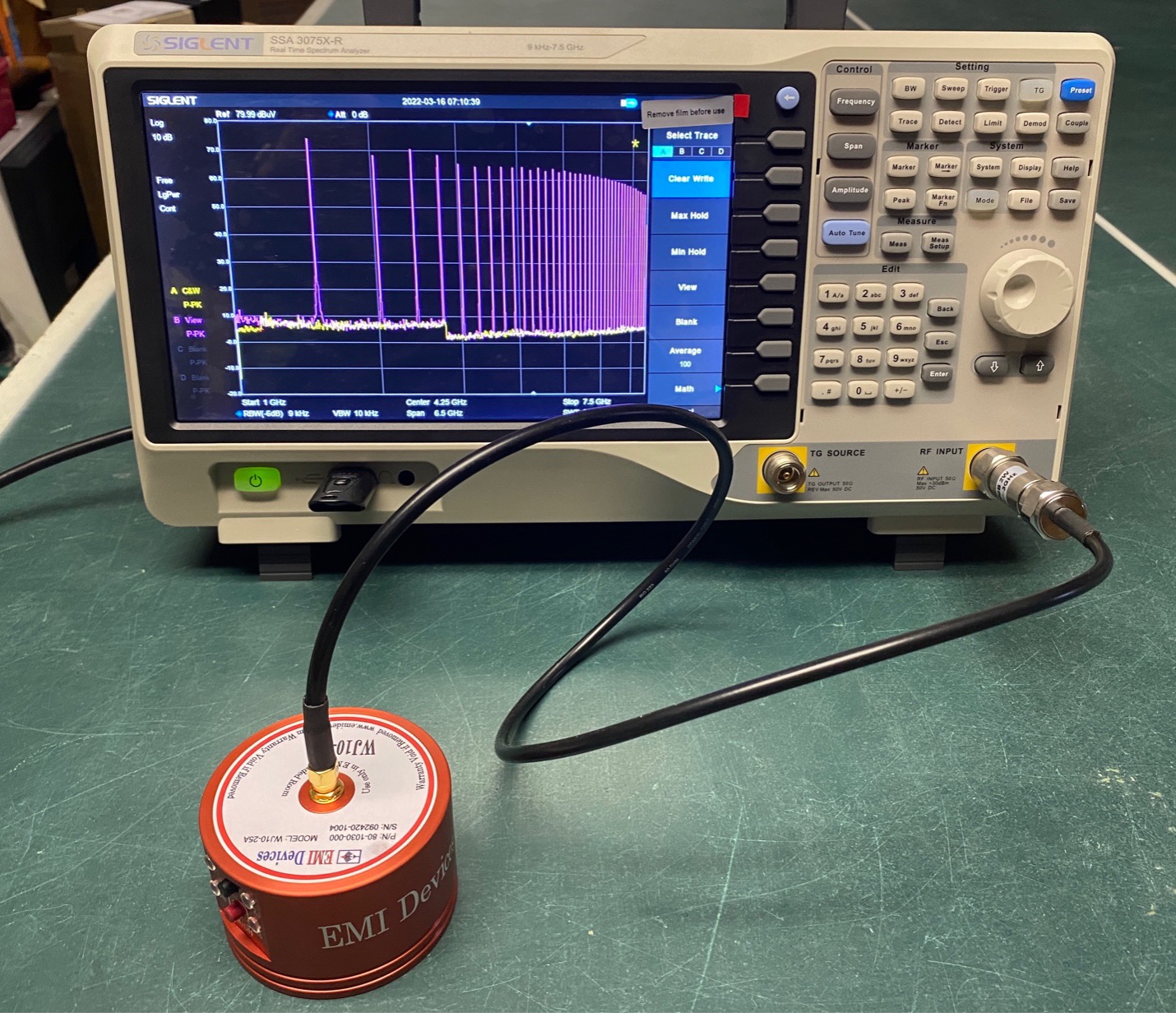

• List all test equipment used during the tests.

-Test equipment type

-Manufacturer

-Model number

-Serial number

-Calibration date and calibration due date

• Details of applicable regulatory compliance labels showing label details and location on the product.

• List of all components of the EUT system. Include in- ternal components such as power supplies, mother- boards, hard disk drives, floppy disk drives, CD-ROM drives and add-in cards.

-Equipment type

-Manufacturer

-Model number

-Serial number

• List of all cables

-Length

-Type (shielded, unshielded, coax, etc) ◦ Devices interconnected with the cable

• EUT exercise/stimulation software used

• Any required user warning statements.

As you can see, preparation for testing a product to EMC requirements is an intensive process. You will need to go through this list of information and make sure that any of it that must be provided to the laboratory is identified and provided in a format that is useful to the laboratory.

Talk to them in advance and make sure that you have everything they need, in a format that they can use. The time (and money) that you save is your own (or your employers).