Today, Suspect Counterfeit ESD Control and Non-Compliant Packaging is a growing issue throughout the Global Supply Chain. EEE parts (ESD sensitive devices) damage transcends circuit cards, touch screen displays, handheld devices, and other microprocessor driven products. Suspect counterfeit static control or non-compliant electrostatic discharge (ESD) shielding bags can be purchased over the internet, in tech-savvy catalogs, GSA approved suppliers, recognized brokers, authorized and unauthorized distributors or direct from a manufacturer.

The author is the First to Present on Suspect Counterfeit and Non-Compliant ESD Materials in the Supply Chain at the NASA Quality Leadership Forum 2010, Cape Canaveral, Florida. No longer can a Supplier Technical Data Sheet serve as proof of compliance for a static control shielding bag. The end-user (who is ANSI/ESD S20.20-2014 compliant) is required to have traceable in-house or 3rd party ANSI/ESD traceable test data for static control products used in and out of the ESD Protected Area (EPA).

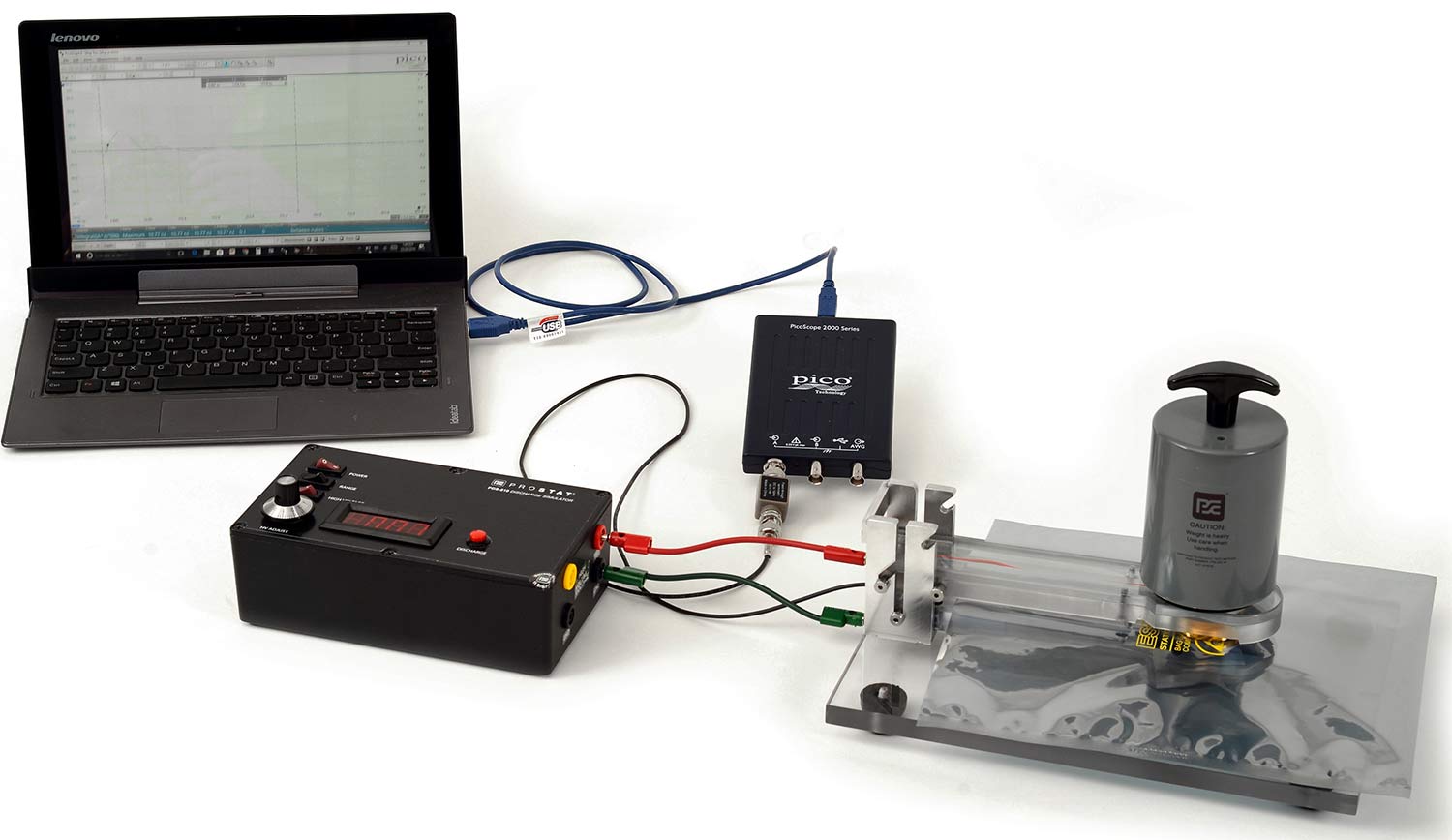

Figure 1

ANSI/ESD S541 is the standard for ESD safe Packaging Materials (ANSI/ESD S20.20 program) that incorporates the following test methods for ESD Qualification: ANSI/ESD S11.4, ANSI/ESD STM11.11, ANSI/ESD STM11.12, ANSI/ESD STM11.13, ANSI/ ESD STM11.31 and ESD Adv. 11.2.

ANSI/ESD S11.4 lists qualification requirements for Static Control Bags. Section 6.0 Markings (ESD S11.4) that calls out: “All bags should be marked with information that allows traceability to the packaging manufacturer and to the manufacturer’s date/lot code information.”

In this article, the commercial designation of Level 3 is used for static shielding bags. Note the Department of Defense (DoD) uses the term “Type III” for static shielding bags.

In this article, several testing methods employed for formal ESD qualification were conducted at 12%±3%RH, 730±50F (230C±30C) for 48 hours minimum as follows:

- Surface Resistance; inside and outside of bag per ANSI/ESD STM11.11 at <1.0 x 10(11) Ω

- Volume Resistance; inside of bag to plate per ANSI/ESD STM11.12 at <1.0 x 10(11) Ω

- Electrostatic Decay per MIL-STD-3010C, Method 4046 (±5kV to ±500 volts or lower) at 2.0 seconds max (various RH and Temperature levels were utilized)

- Charge Retention (Faraday Cup) per ESD 11.2 at <1.0 nC

- Static Shielding; 12%RH and 50%RH per ANSI/ESD STM11.31 at <20 nJ

An accredited ESD laboratory is a valuable resource to verify static control materials and packaging for qualification testing per ANSI/ESD S541. Several online advertised labs have been known to deviate from the environmental conditioning requirements for ANSI/ESD S541 compliant testing. For example, some will conduct ESD testing at ambient or room conditions even though low RH preconditioning (12%±3%RH) is required. Or, just as bad, one should never pull product out of a dry chamber to test at ambient conditions!

This haphazard approach to ESD testing may account for significantly different costs when required testing protocols are circumvented. In an unregulated industry, this practice appears to be the norm for some labs due to the divergent test results for static control materials.

Many static control materials are topically coated with antistats that rely on moisture in the air for performance. Today, it is probable that topically coated antistat packaging material will pass at 50% RH yet fail at 12%RH.

Due to the rise of suspect counterfeit ESD packaging & materials in the supply chain, Google Earth is a valuable tool for the end user to ensure that a test lab is not located on an empty lot, home garage, a shack or PO Box. ESD Test Labs because of proprietary technologies must be safeguarded with limited access. Equally important is lab grade, calibrated instrumentation in a controlled environment.

Utilizing advanced instrumentation for ANSI/ESD S541 material qualification testing will better ensure static control packaging integrity for the protection of EEE devices. From Aerospace & Defense to the pharmaceutical and medical device sectors, reliability and repeatability of test results will protect the consumer as well as the safety of patients and for soldiers in the field.

SURFACE RESISTANCE VERSUS RELATIVE HUMIDITY (RH)

At the insulative range, humidity dependent materials become nonconductive and hold static charges for several seconds or more. In practice, however, a lower cut-off is often desired for packaging materials because dry air may be encountered during staging, shipping, material handling, and storage. In cold and dry climatic conditions, relative humidity can drop to <4%. Surface resistance testing constitutes a boilerplate ESD test method for the evaluation of static control materials. At 1.0 x 1011 Ω, and above, materials are nonconductive (exhibit insulative properties) and hold static charges for several seconds to days. Surface resistance rises when relative humidity (RH) is lowered. In everyday use, Tribocharging can contribute to damage by Field Induction

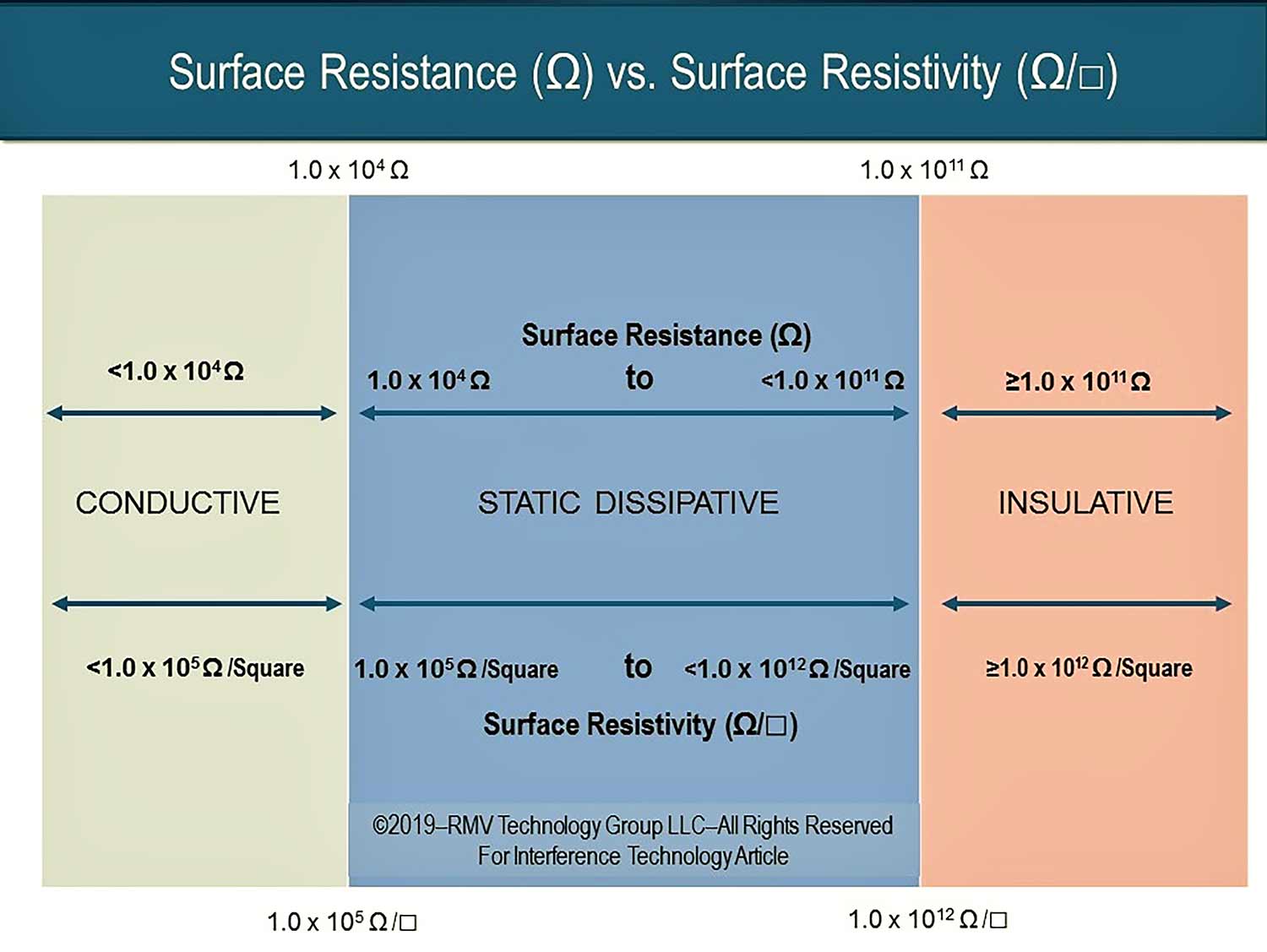

Table 1 – depicts the surface resistance classification in ohms per ANSI/ESD S541 for Packaging & Materials) and ASTM D257 for surface resistivity in ohms per square.

SURFACE RESISTANCE PER ANSI/ESD STM11.11

Figure 2 – Left Figure 2 – Right

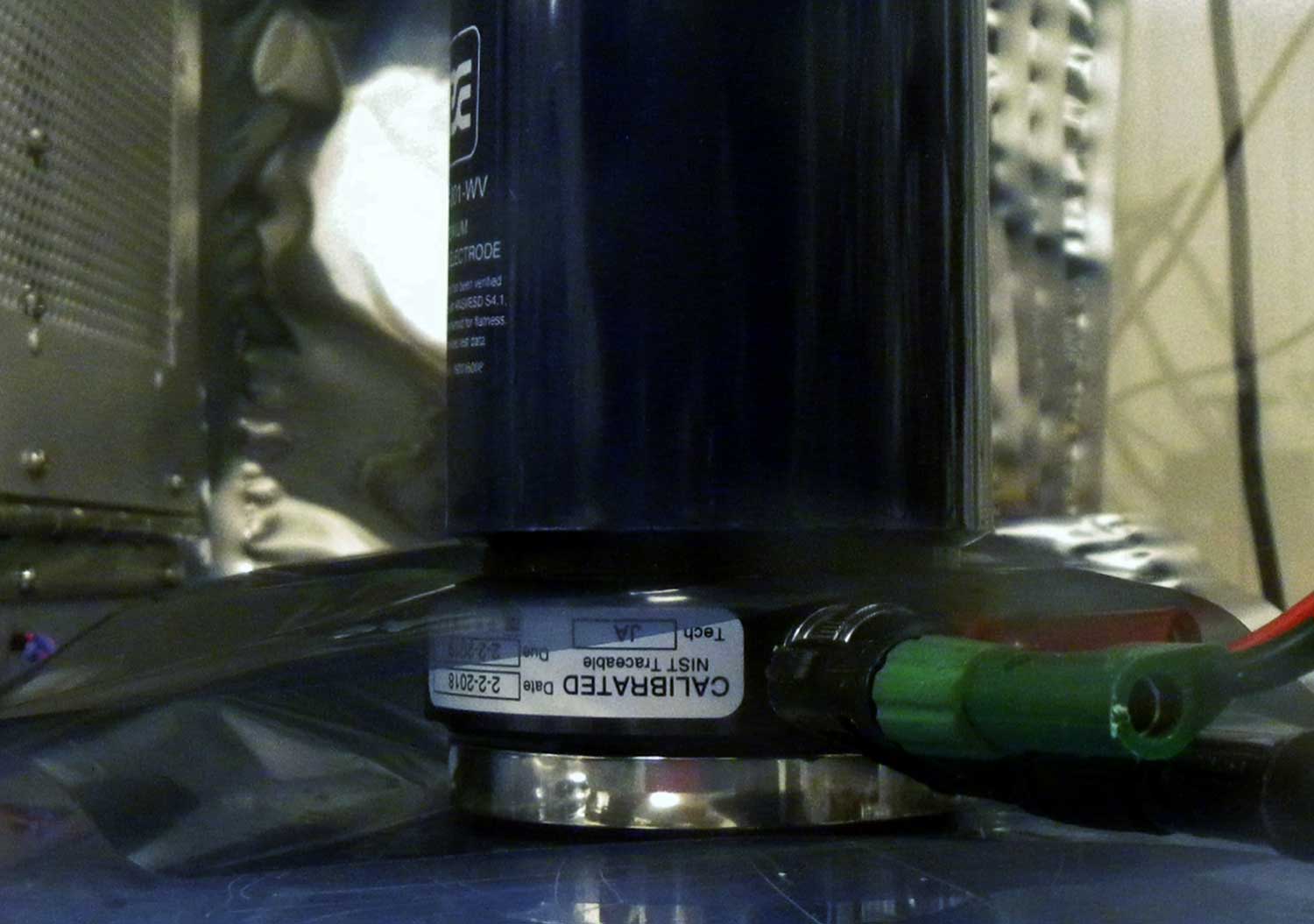

A concentric ring fixture is utilized to measure the outside and inside of bags. To ensure the electrometer and concentric ring are in calibration, a favorable reference measurement of 1.0 x 10(12) Ω is verified for compliance to ANSI/ESD STM11.11 (see Figure 2, left and right).

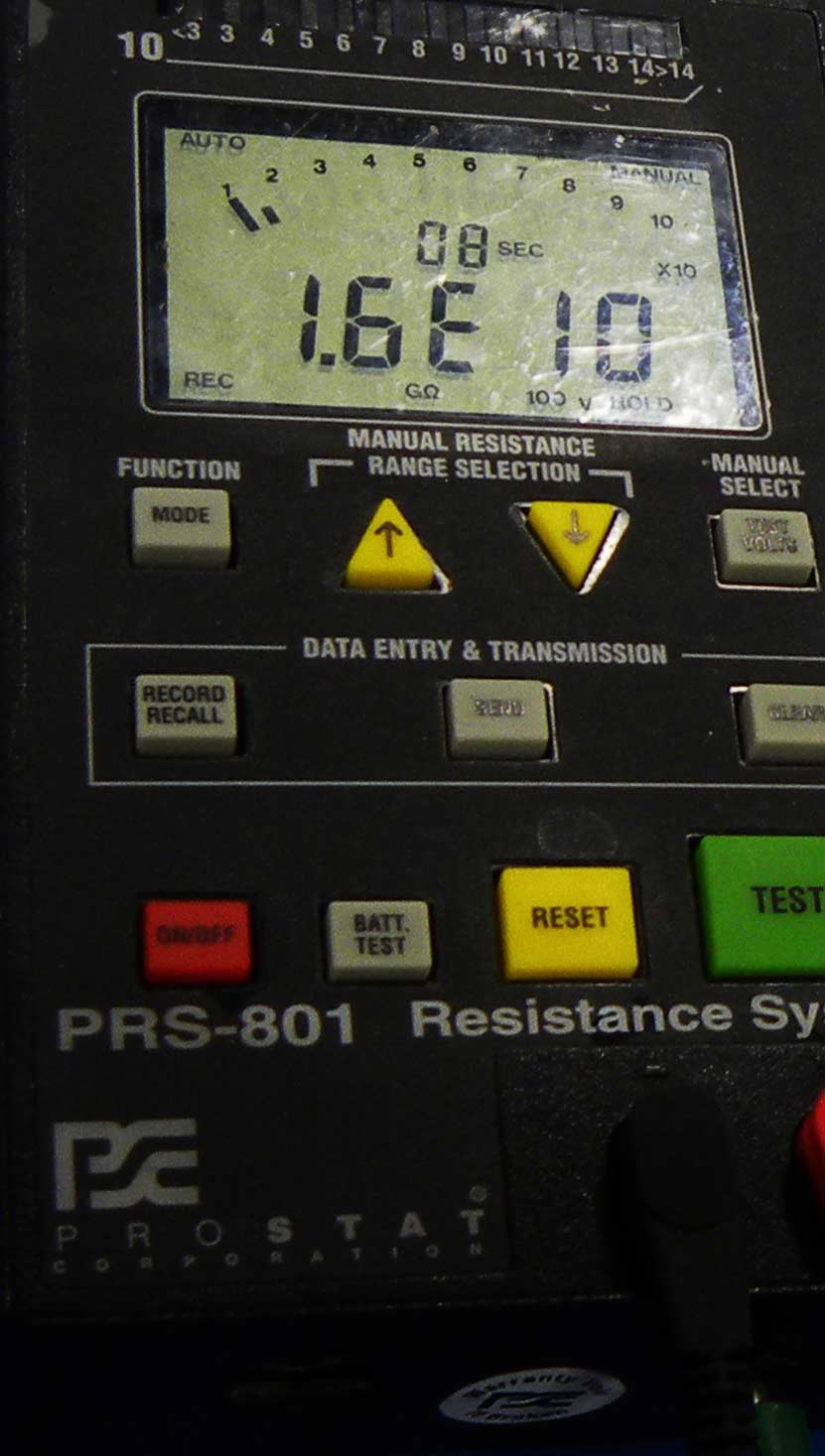

Figure 3

ANSI/ESD STM11.11 is employed to measure the surface resistance of the Level 3 (Type III) vacuum deposited metalized static shielding bag. In Figure 3, the surface resistance for the inside of the bag measured 1.6 x 10(10) Ω under the limit of <1.0 x 10(11) Ω.

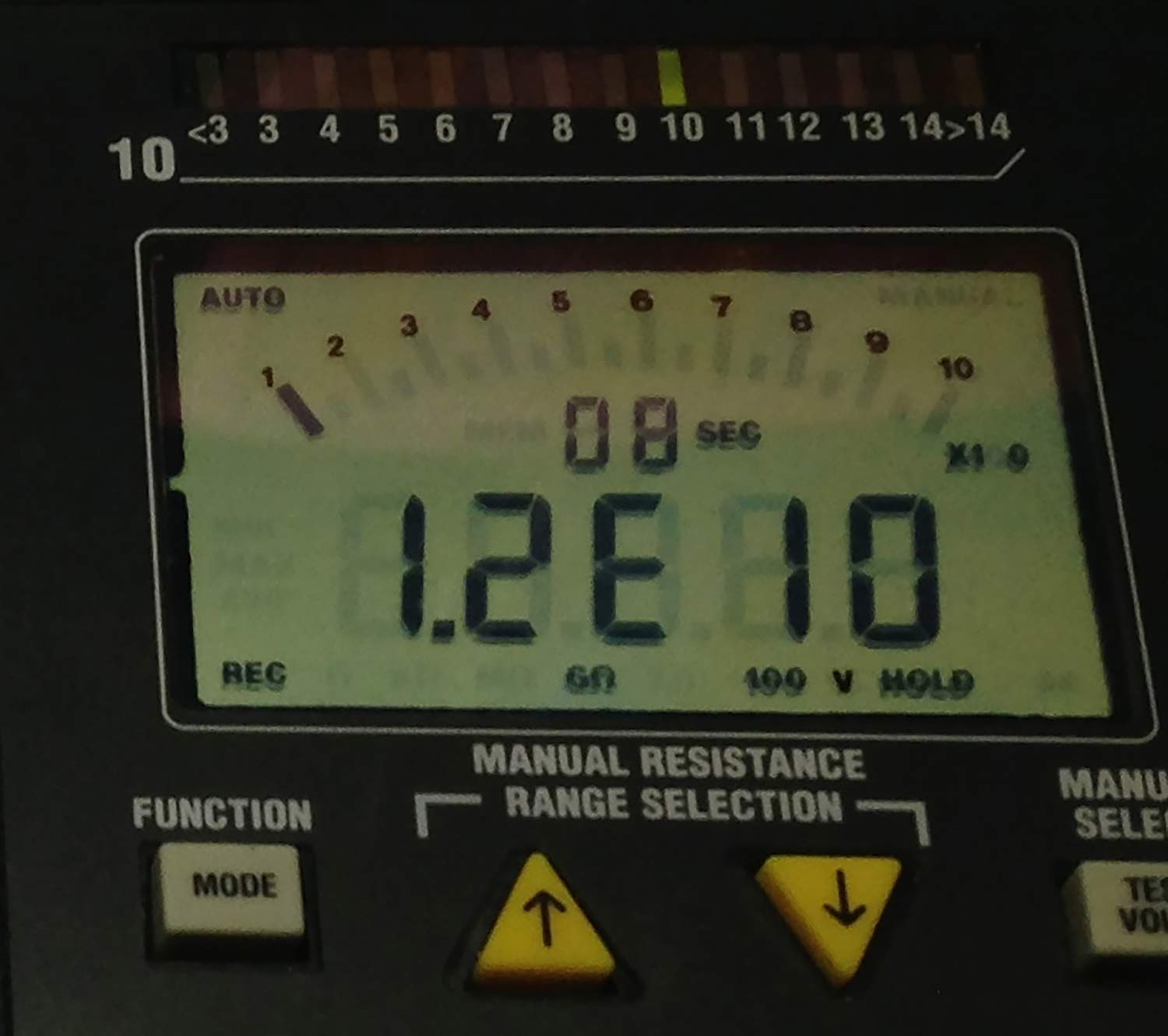

Figure 4

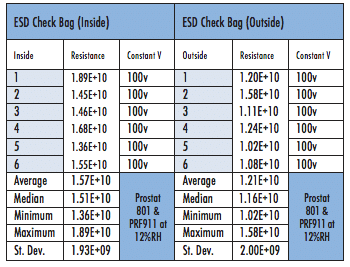

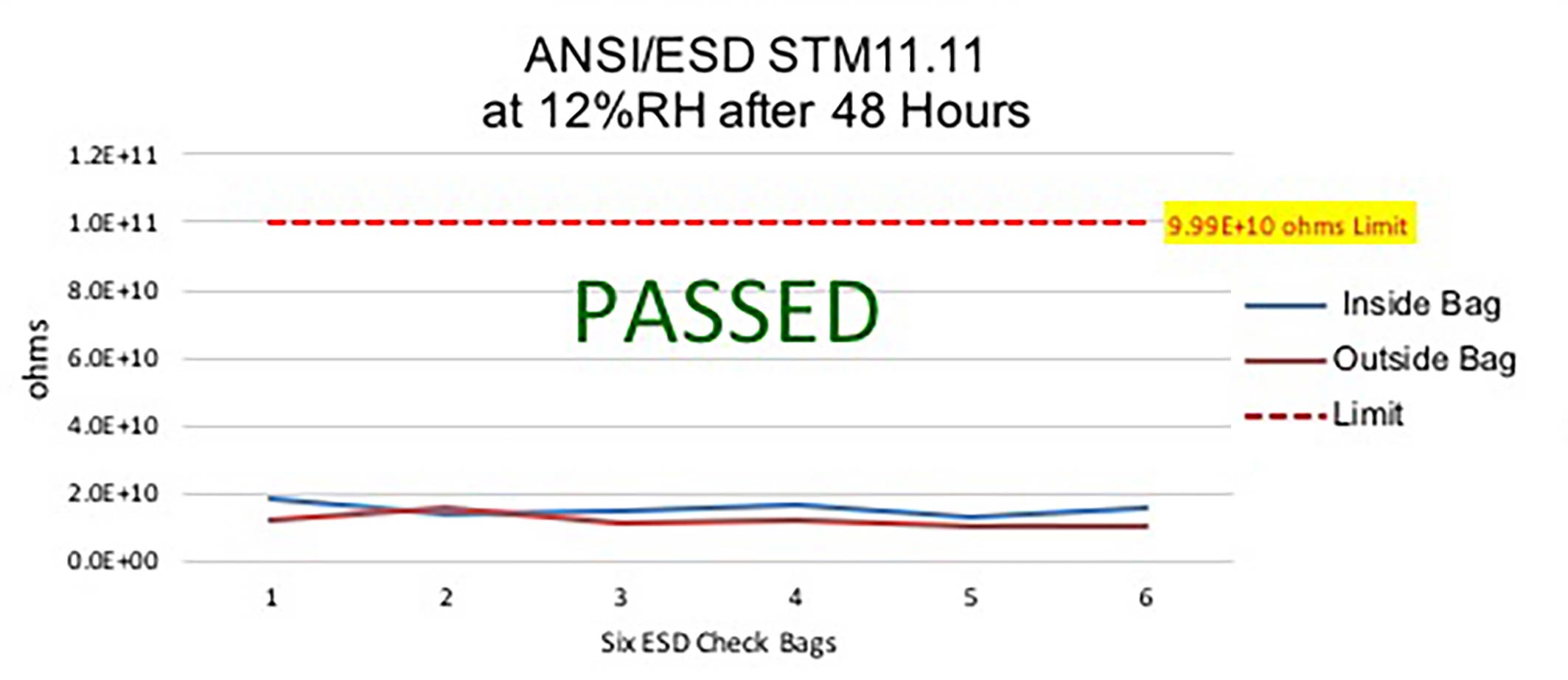

In Figure 4, the outside of the bag measured 1.2 x 10(10) Ω (<1.0 x 10(11) Ω). Test results are listed in Table 2 of this article. Note: Samples must be measured at 12%±3%RH without removal from the chamber during any part of the evaluation process for ESD lab integrity and to maintain compliance with the standard.

Table 2 – 12%RH at 73.40F after 48 hours of preconditioning

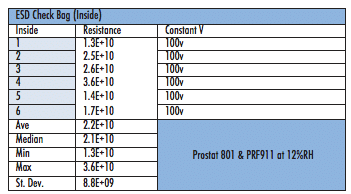

Table 3

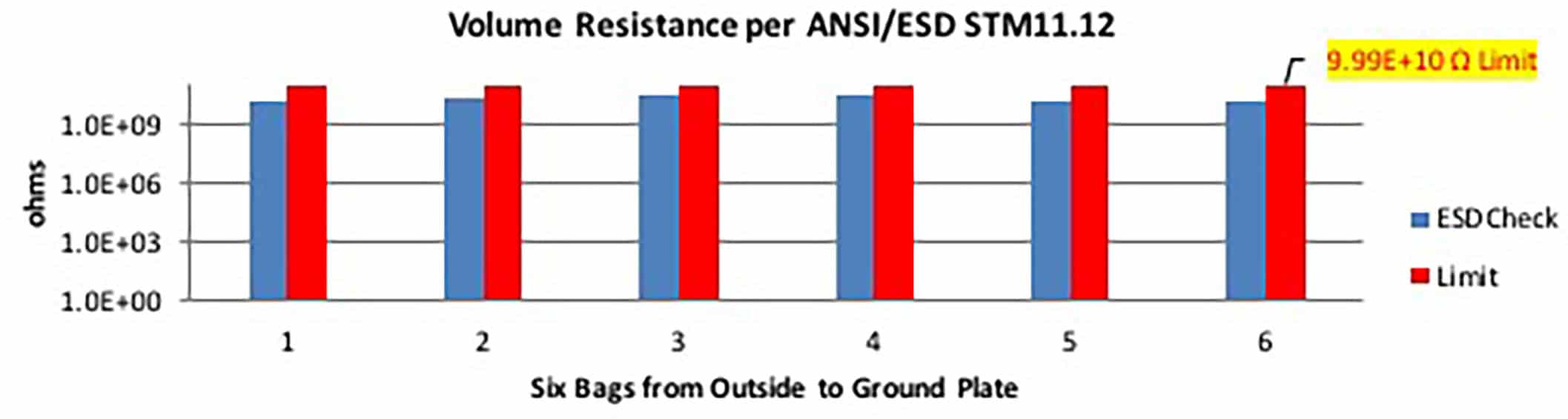

VOLUME RESISTANCE PER ANSI/ESD STM 11.12

Figure 5

ANSI/ESD STM11.12 defines the standard test procedure, equipment, sample preparation and conditioning required to achieve reproducible volume resistance test results on static dissipative planar materials. This test will determine if charge bleed-off could occur when a static control bag is opened in the ESD Protected Area (EPA). Results were within acceptable levels as illustrated in Table 4.

Table 4 – ANSI/ESD STM11.12 at 12.3%RH, 72.30F for 48 hours

Table 5

In short, the static shielding bags provide favorable volume resistance in compliance with ANSI/ESD STM11.12.

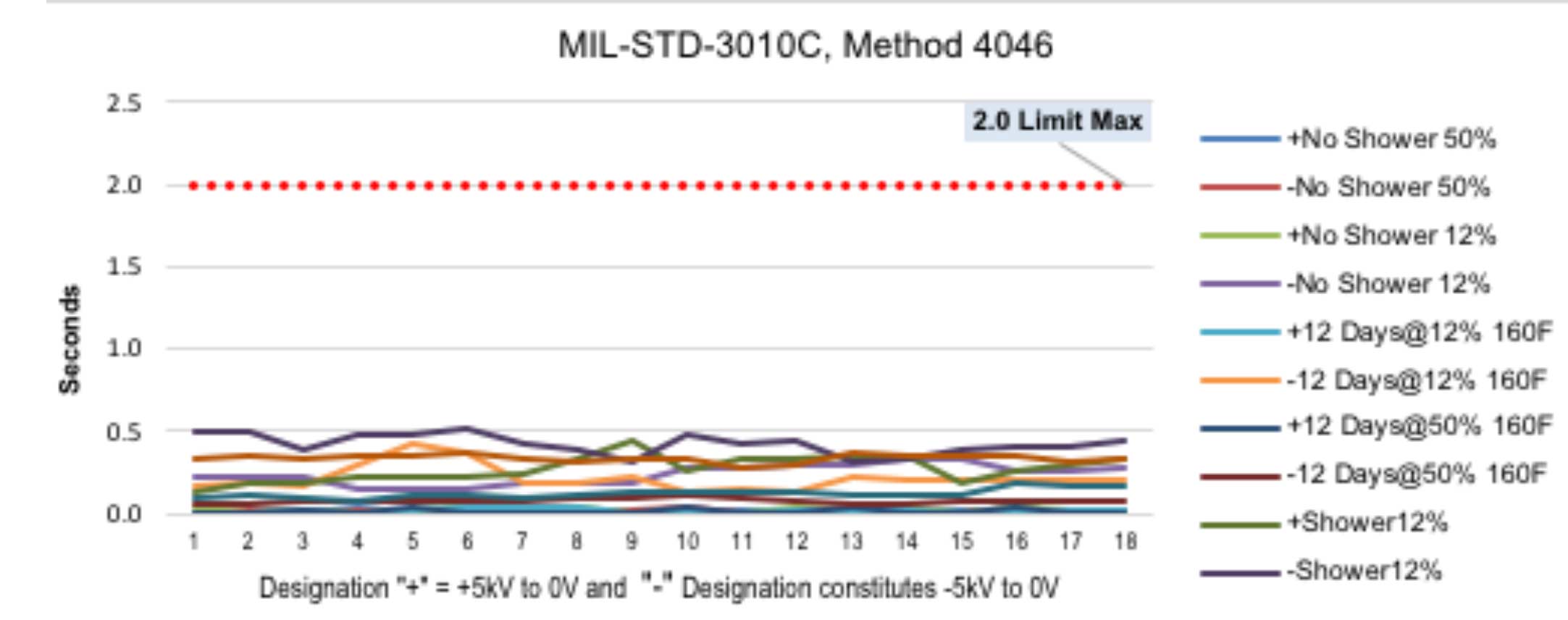

ELECTROSTATIC DECAY PER MIL-STD-3010C, Method 4046 (1 Aug 2013)

The latest revision for MIL-STD-3010C, Method 4046 (1 Aug. 2013) section 5.4.3.4.2 (after 160 ±5 ºF oven conditioning for 12 days) states: Test environment. Immediately after preconditioning, unless otherwise specified in the test plan, all specimens shall be placed in the electrostatic test chamber (maintained at 73±5ºF and 12±3% relative humidity) for a minimum of 24 hours; for this testing sequence, 48 hours of preconditioning after oven and dry conditioning took place.

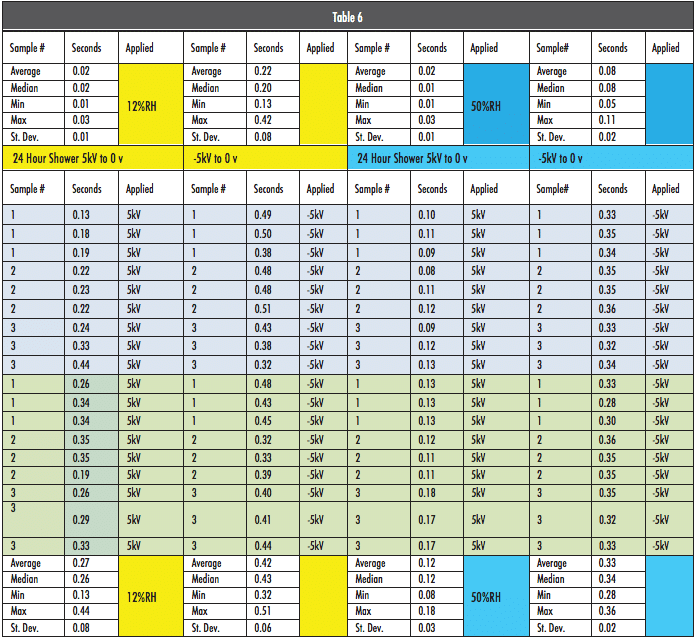

FIGURE 6

FIGURE 7

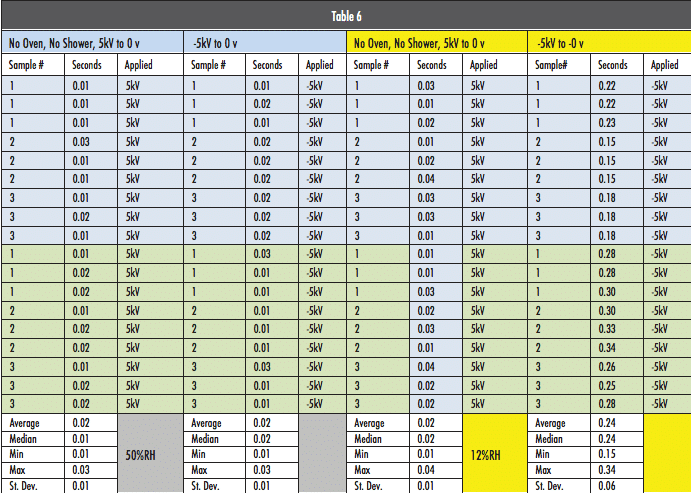

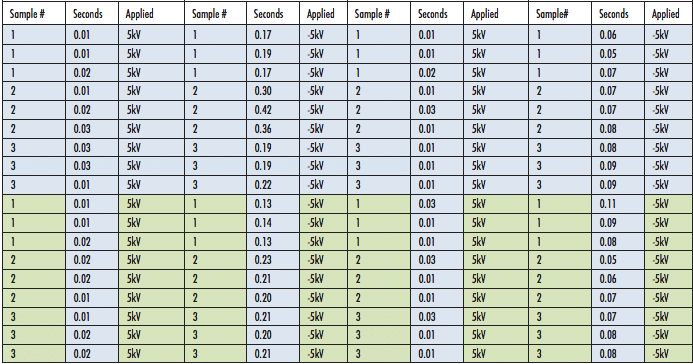

After preconditioning, the six samples were evaluated for electrostatic decay from ±5kV to ±0 volts. For Type I & III ESD bags, the DoD sets an electrostatic decay time at 2.0 seconds maximum. Using a calibration fixture, said decay test unit was verified at 0.28 and 0.27 seconds respectively and within the level of acceptance. Note: The decay test was modified from ±5kV to ±500 volts for a cutoff at 0 volts to represent a worst-case scenario. The 3” x 5” samples were cut after completion of other electrical tests in the length (blue) and cross (green) direction as illustrated in Table 6 (see below). Table 7 illustrates passing decay results.

Table 7

It should be noted that electrostatic decay testing is required by many end-user organizations. In this case, the results in Table 5 passed. However, Military Handbook 263B states in Appendix I: “… Decay time measurements, for an induced voltage on a given sample, may not correlate with surface or volume resistivity measurements for materials of complex construction.

Table 6 – pt. 1

Table 6 – pt. 2

Additionally, decay time measurements can become complex from the viewpoint of understanding exactly how materials of complex construction, that is, laminates/ multilayer materials, are performing…”

Figure 8

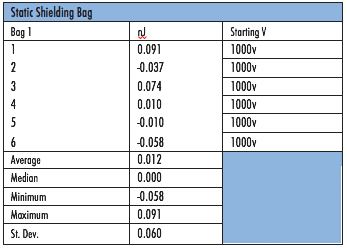

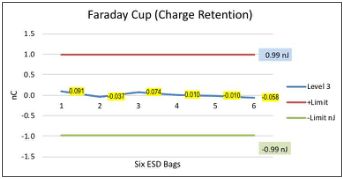

CHARGE RETENTION USING A FARADAY CUP PER ANSI/ESD ADV.11.2 (Modified)

ESD Adv.11.2, Appendix D calls out a Faraday Cup charge retention test required by some end-users in the ESD Materials Qualification Process. Said test requires skill to reproduce findings without human influence. This test was conducted at 12%RH ±3%RH after 48 hours of preconditioning. In Figure 8 (left), the static shielding bag is positioned on a charge plate. Six static shielding bags were charged to 1000 volts and then removed from the charge plate by the grounded evaluator at 11.8%RH.

Six Level 3 bags were released to free fall into the Faraday Cup. The results are illustrated in Tables 8 and 9; the static shielding bags passed the test with a peak charge of <±1.0nC.

Table 8 12%RH after 48 Hours of preconditioning

Table 9

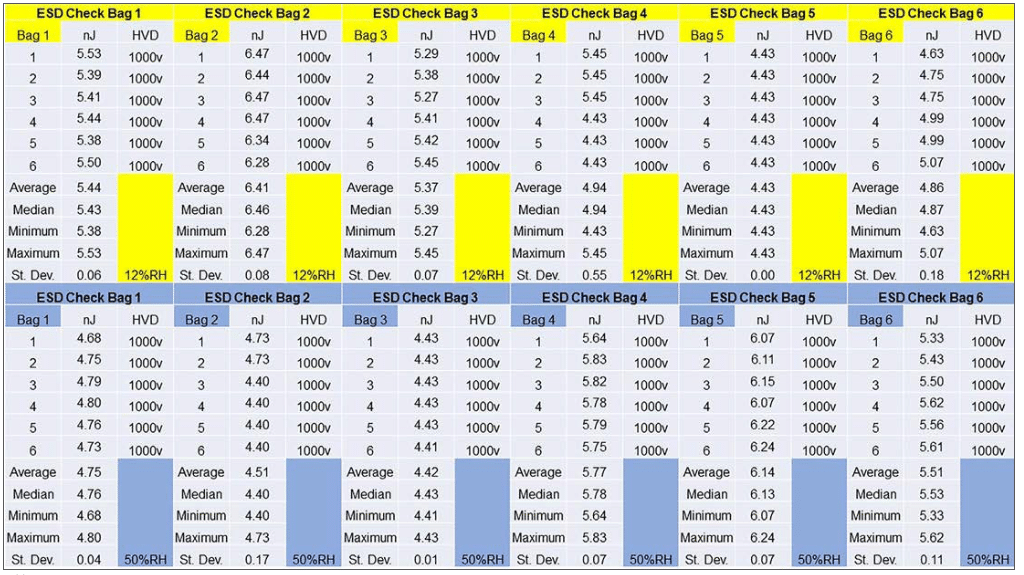

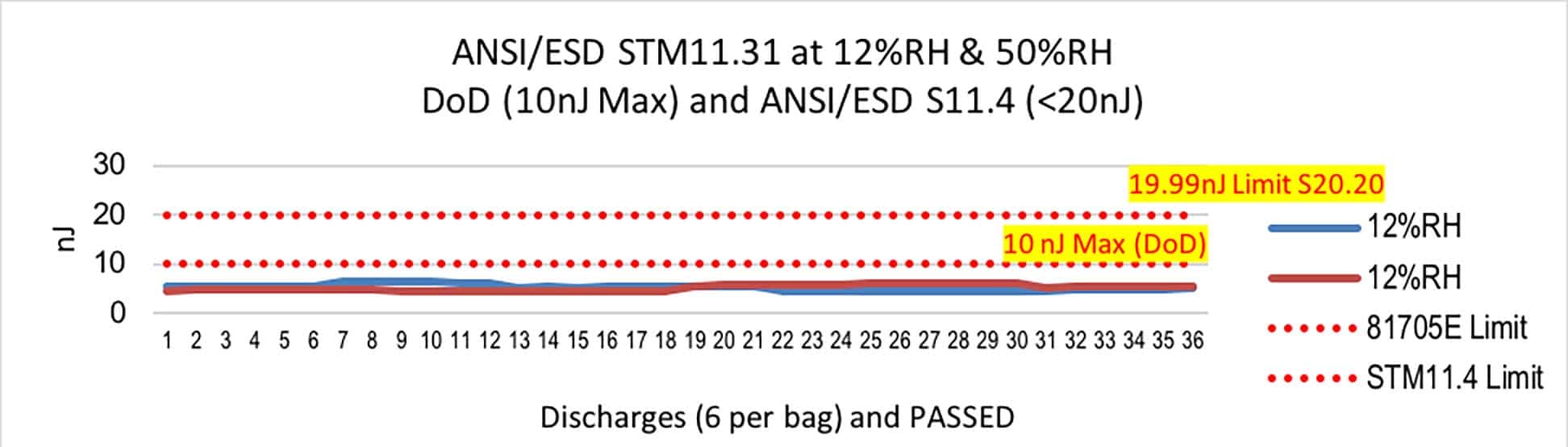

ELECTROSTATIC SHIELDING PER ANSI/ESD STM11.31

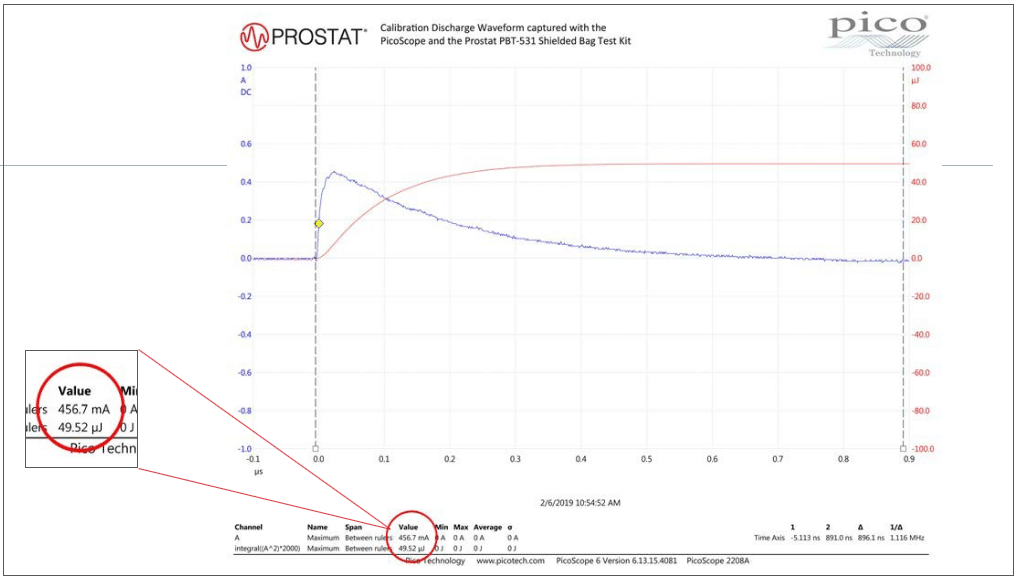

Figure 9

ANSI/ESD S20.20-2014 calls out ANSI/ESD STM11.31 per ANSI/ESD S541. ANSI/ESD S11.4 calls out a limit of <20nJ. Six discharges per bag were conducted. ANSI/ESD STM11.31 provides a test method for determining the shielding capabilities of electrostatic shielding bags. Said method employs a capacitive sensor inside the package. A 1KV discharge to the outer package was conducted; the fixture then measures the current across a resistor connected to the fixture’s upper and lower sensing plates. This test has the objective of measuring energy per specified RH levels (at 12% or 50%). See below Figure 10.

Figure 10

Table 10

Table 11

The static shielding bag under test allowed <7.0nJ to penetrate the structure. Thus, the static shielding bags measured <20nJ and are ANSI/ESD S20.20 compliant.

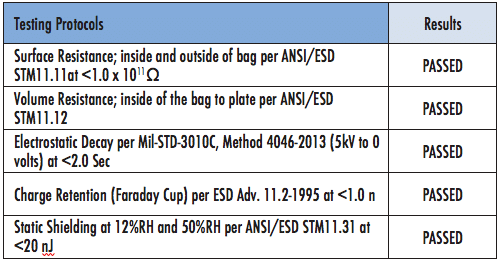

In summary, the test methods utilized for formalized ESD qualification testing are as follows:

Table 12

In short, said testing methods for evaluation are traceable to ANSI/ESD S541 and MIL-STD-3010C, Method 4046.

This article clearly demonstrates that qualification of ESD control packaging as with any static control product from the USA, Eu- rope, Mexico, Central, and South America, and Asia-Pacific must follow a formalized qualification process. In this instance, the ESD bags are suitable for use inside and outside the ANSI/ESD S20.20- 2014 ESD Protected Area. Moreover, ESD product qualification needs to be combined with periodic verification of incoming materials and packaging during the product life cycle to prevent substitution or downgrading of static control products. The ever increasing expansion of suspect counterfeit materials and packaging in the global supply chain demonstrates how important it is to use vetted ESD test labs that are credentialed and adhere to a code of ethics. Trust but verify a potential ESD test lab before issuing a purchase order as is done with other proven suppliers.

Author’s Note: Special Thanks to Frank Coloccia of Prostat Corporation for providing the ESDcheck® Bag for Level 3 test specimens (fcoloccia@prostatcorp.com or 630.238.8883).

REFERENCES

- ESD 1.0

- ANSI/ESD S54i

- ANSI/ESD 20

- ANSI/ESD 11

- ANSI/ESD 12

- ANSI/ESD STM 31

- MIL-STD-3010C, MTD 4046

- ANSI/ESD S11.4 (Static Shielding Bag Standard Following ESD Materials Validation Process, Controlled Environments, Bob Vermillion, August 26, 2010

- Pin Holes & Staples Lead to Diminished Performance in Metallized Static Shielding Bags, In Compliance, September 2013, pp 42-48, Bob Vermillion