Surface cleanliness is critical to good coating adhesion for any coating process

Rocky R. Arnold, Ph.D.

WaveZero, Inc.

Sunnyvale, CA

Many medical product manufacturers achieve electromagnetic compliance (EMC) for their electronic devices by coating the inside of the plastic enclosures with a conductive material; for example, silver-copper particle loaded paint, electroplated tin, or vapor-deposited (e.g., vacuum-metalized) aluminum or alternative metal.

In the last decade, the use of vapor deposited metals has seen increased use as both the process and coatings are environmentally friendly (e.g., green), and modern processes used for application of the coating are increasingly sophisticated and highly effective both in terms of achieving high coating adhesion and low surface resistivity. Conductive paint is used less often these days because of its potential for cracking and flaking which can create conductive particles that foil the electrical operation of the device. Obviously, medical product manufacturers take this risk very seriously. Electroplating is also declining in use because the processes tend to create high volumes of toxic waste which must be processed at added expense.

While vacuum metalization is preferred for the reasons given, in recent years the changes in composition of plastic resins has become problematic for all coating providers. For instance, because of the advent of the European Directive 2002/95/EC on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic equipment (RoHS), providers of plastic resins used by injection molders to make the plastic enclosure have eliminated brominated materials which are banned by RoHS in favor of other fire retardant additives that allow the plastic to pass requirements for flame retarding capability. These flame retardant material additives can reduce coating adhesion dramatically and thus are of great concern to providers of coatings.

In addition to excellent coating adhesion, medical OEMs seek conductive coatings that provide (1) a minimum surface resistivity (Ohms per square) and (2) a minimum point-to-point (P2P) resistance (Ohms). Achieving these specifications assures the OEM that the metal coating provides the required level of electromagnetic interference (EMI) shielding consistent with the design of the enclosed electronic devices.

In this article, we examine an actual case of a medical electronic product enclosure made from plastic resin materials that contained flame retardant additives that were especially deleterious to coating adhesion. The medical device was a universal programmer for implantable cardioverter defibrillators (ICD) and pacemakers. The medical device was in the form of a portable computer used for quick and efficient follow-up testing in a doctor’s office. The PC-based medical electronic device analyzes data from the ICD or pacemaker and combined with clinical data on the patient, enables rapid re-programming of the implantable devices. The device is now being sold in quantities of thousands of units per year, and patient satisfaction is reported to be very high.

Vacuum deposition or vacuum metalization is a well-proven approach for consistent and effective coatings for the inside of electronic product enclosures. This approach was chosen by the medical device OEM after considering the alternatives mentioned above.

Early Technical Issues

Vacuum metalization provides a relatively thin coating on surfaces located within the vacuum chamber. One to six microns total thickness is typical depending upon the metals and processes used. Also referred to as a functional thin film coating, a vacuum-metalized coating is known for its ability to provide cost-effective EMI shielding on plastic parts, especially on injection-molded enclosures. A major requirement for good adhesion, however, is that the surfaces to be metalized are relatively clean and thus have minimal or no surface contamination that could interfere with the in-chamber processes.

As with most, if not all, medical devices incorporating digital, analog, and RF electronics, radiated emissions is a key EMC issue as no medical device can be sold without first demonstrating its compliance with EMC requirements (CISPR 22, in this case). And, while early on, the exact emissions spectrum for the electronic product was not known, it was decided to use a three-layer metal coating comprised of (in order) stainless steel, copper, and stainless steel. This particular coating system provided a high degree of E-field shielding and some H-field shielding. More importantly, this particular coating had been proven in a myriad of medical and military systems going back over 10 years.

The OEM selected a GE resin, Cycoloy C6200, for the majority of enclosure parts (a total of eight individual pieces that fit together like a model kit). It was quickly discovered that coating adhesion was not adequate.1 Historically, plastic parts are cleaned when coating adhesion is a problem and was done in this case to no avail. Eventually, it was suspected that the Cycoloy C6200 contained an internal substance (such as a flame retardant) that was outgassing during the vacuum metalization process and thus preventing good consolidation of the coating material with the surface. A large number of tests were conducted to verify that the amount of outgassing was relatively very high and steps were taken with the vapor deposition processes to control the amount of outgassing.

While it was not absolutely confirmed as to which chemical was the major contributor to outgassing, it was strongly suspected that triphenal phosphate (TPP) was the culprit because of its low boiling point2 and its recently increased usage in plastics as a replacement for brominated materials which are outlawed by the RoHS Directive.

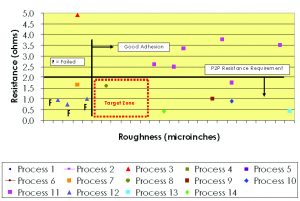

Even with the reduction in outgassed substances, coating adhesion continued to be below acceptable levels. It was decided at that point that roughening the surface (post injection molding) would provide improved adhesion. A number of surface roughening experiments were conducted, and they confirmed that coating adhesion was adequate to superior, depending upon the amount of roughness. However, with increased surface roughness came a dramatic increase in point-to-point (P2P) resistance.3 Thereafter, the question of how much P2P resistance was too much had to be addressed.

Final Experiments and Results

Each of the eight pieces used to form the enclosure had a specified maximum allowable P2P resistance of 2.0 Ohms which was needed to assure the high performance of the electronic device. This limit value was based on the design and electrical evaluations conducted by the OEM. The coating on the enclosure parts is electrically connected to a ground plane within the printed circuit board via standoffs (containing screwed metal sleeves) located on both front (as shown in Figure 1) and rear enclosure halves. P2P testing was conducted between any two standoffs; however, as P2P resistance is a function of surface roughness and separation distance, standoffs located the furthest apart controlled the requirement.

Three complete enclosure sets had their surfaces roughened using a standard grit formulation. Each set of enclosure parts were roughened by different amounts to provide the goal P2P resistance values of 2 Ohms, 6 to 8 Ohms, and 15 Ohms. They were then vacuum metalized. The OEM then assembled complete units and subjected them to EMC testing to determine their spectrums of radiated emissions. It quickly became clear that only units with P2P resistance less than or equal to 2.0 Ohms would be acceptable.4 It was also evident that achieving the P2P resistance requirement required a surface that had very little additional surface roughness AND was extremely clean.5 Indeed, the requirement for coating adhesion conflicted with the P2P requirement; that is, increasing surface roughness to achieve coating adhesion only made the P2P resistance higher. Thereafter, a systematic evaluation of surface roughening substances, cleaning materials, cleaning processes,6 and vapor deposition processes was conducted to determine the optimum surface roughness needed to achieve both a maximum P2P resistance and good coating adhesion.

The results are shown in Figure 2. Fourteen different combinations of roughening materials, cleaning materials, and processes were evaluated. Eventually, a “target zone” of preferred surface conditioning was discovered. With more experiments (not shown), an ideal combination of materials and processes was developed that provided reliable results in a production environment.

With proper surface roughening and cleaning and optimized vapor deposition processes to control internal contaminants, high coating adhesion was achieved.

Conclusions

Surface cleanliness is critical to good coating adhesion for any coating process and vacuum metalized coatings are no exception. It was discovered that internal contaminants can also be brought to the surface by the deep vacuum, thus interfering with the vapor deposition processes. Roughening the surface to achieve good adhesion, while always possible, is, in most circumstances limited by the concurrent need to limit P2P resistance. Apparently, only a highly optimized combination of processes is sufficient in some situations. The OEM’s medical device passed all applicable EMC tests and is now being marketed and sold throughout the world.

Endnotes

- WaveZero used a non-destructive adhesive tape test (equivalent to the destructive testing specified in ASTM 335902) that it developed. The adhesive tape test and selected tape were approved by the OEM.

- Materials, like TPP, which have relatively low boiling points (698° F at room temperature), have a greater propensity to become volatilized in deep vacuum (1 x 10-6 torr, for example).

- Roughness increases the electrical path length according to the number and size of microscopic hills and valleys over which current must travel. It was discovered experimentally and confirmed analytically that even a very modest increase in roughness can easily double the electrical path length over that of an absolutely smooth surface.

- The OEM specifications called for a minimum 5-dB separation between maximum tested peak and the FCC emissions requirement.

- Achieving the desired P2P resistance could be accomplished by doubling the coating thickness; however, this would require the metalization process to be accomplished twice virtually doubling the cost.

- Cleaning processes include both pre-metalization washing and in-chamber plasma processes.

For more information, please contact moreinfo@wavezero.com.