Thin and flexible materials can provide simple and innovative solutions for hardware engineers

Jung-Ju Suh, Ph.D. Electrical Markets Division, 3M Korea; Seoul, South Korea

INTRODUCTION

Electromagnetic interference issues can arise anywhere in electronic equipment with unpredictable and troublesome effects. These issues challenge hardware design engineers, and the challenges escalate as today’s electronic equipment becomes both thinner and multifunctional. For example, modern cellular phones are being equipped with high-speed microprocessors, wireless LANs, Bluetooth, MP3s, cameras, motion sensors, touch screens, GPS and many other devices. Although there have been significant advances in device and PCB design technology that reduce electromagnetic interference (EMI), RF noise remains one of the most difficult problems facing design engineers.

Shielding with a conductive material is the most common way of solving RF noise problems. Widely used commercial shielding products include: shield can, conductive gasket, and foil- and mesh-type tapes. The shielding solution envelops the noise source, increases the grounding level, and suppresses radiated noise. However, modern electronic devices operate at hundreds of MHz with harmonic noise emissions in the GHz region. At these high frequencies, the reflected signal in a conductive shielding system can cause serious problems for the shielded device itself and/or for other adjacent components. Moreover, highly integrated electronic systems can create very complex issues around RF noise that cannot be eliminated with simple shielding and grounding techniques.

Recently introduced electromagnetic absorbing products can provide a relatively easy solution for reducing unwanted RF noise. This sheet-type absorbing product is a composite material with magnetic particles embedded in a polymer. It has good noise attenuation performance from hundreds of MHz to several GHz. These materials, with their unique electromagnetic and physical characteristics, have already been used effectively in a variety of applications.

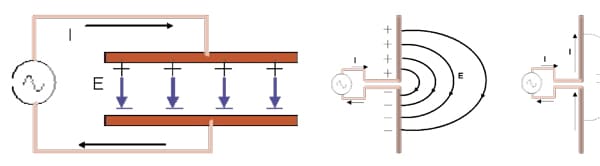

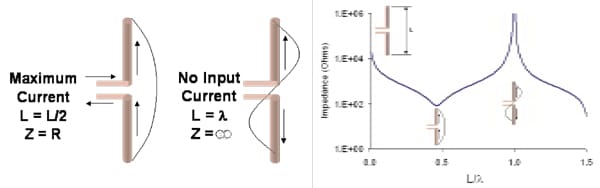

The noise-absorbing phenomenon in a composite absorber can be described in terms of both near-field and far-field applications. In the near-field application, magnetic loss of the absorber plays a dominant role in absorbing high frequency noise. Composite absorbers are magnetic materials characterized by permeability in the range of 10 to 200. These absorbers have stable permeability characteristics at low frequencies. However, they have second order permeability effects at higher frequencies. When very high-magnetic field strength is present, the individual magnetic particles in the composite sheet are unable to follow the applied field instantaneously, resulting in a phase-lag between applied field and magnetization. This phenomenon is represented in the following equation, where μr´is the real part of permeability and μr´´ is the imaginary part of permeability.[1]

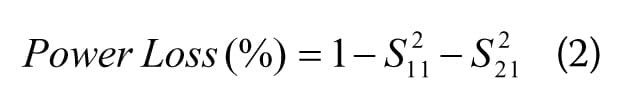

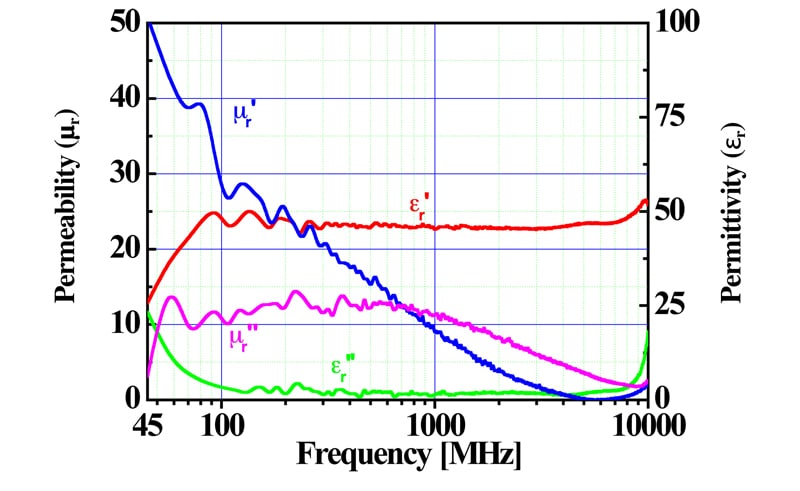

Figure 1 shows the typical permeability spectrum of an absorber sheet as a function of frequency. The pattern of μr” correlates closely with the noise-absorbing performance of the material because it takes into account the magnetic loss, from “ferromagnetic resonance and relaxation.”[2] With an incoming wave at higher frequencies, a phase lag occurs in magnetic spin. Within the absorbing material, the incoming wave energy is converted to a very small amount of heat. This effect can be measured by the Micro Strip Line (MSL) method as shown in Figure 2. Both ends of the MSL, with initial impedance adjusted to 50 Ω, are connected to a network analyzer through coaxial cables to measure the reflected signal S11 and transmitted signal S21 of the noise-absorbing sheet. The energy loss is expressed in the following equation.[3]

Figure 1 shows the typical permeability spectrum of an absorber sheet as a function of frequency. The pattern of μr” correlates closely with the noise-absorbing performance of the material because it takes into account the magnetic loss, from “ferromagnetic resonance and relaxation.”[2] With an incoming wave at higher frequencies, a phase lag occurs in magnetic spin. Within the absorbing material, the incoming wave energy is converted to a very small amount of heat. This effect can be measured by the Micro Strip Line (MSL) method as shown in Figure 2. Both ends of the MSL, with initial impedance adjusted to 50 Ω, are connected to a network analyzer through coaxial cables to measure the reflected signal S11 and transmitted signal S21 of the noise-absorbing sheet. The energy loss is expressed in the following equation.[3]

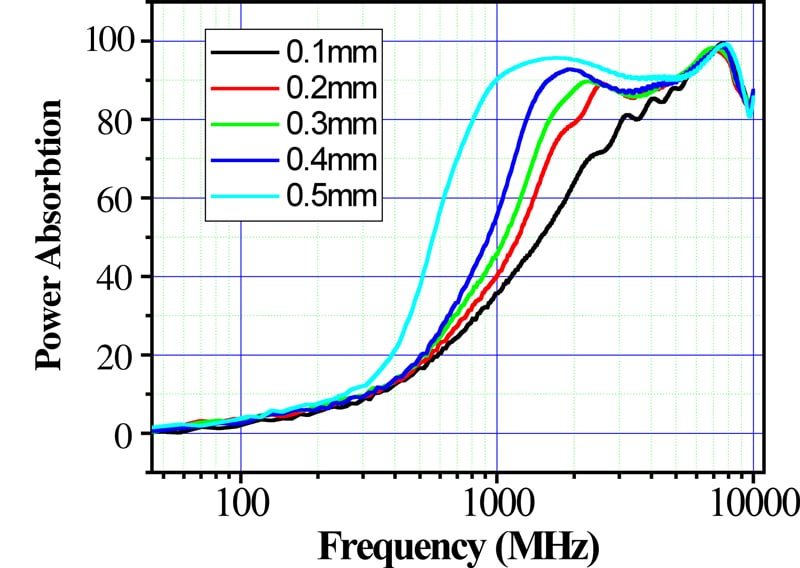

As shown in Figure 3, absorbing performance increases with sheet thickness over a broad frequency range. More than 80 percent of this loss comes from magnetic loss with the remaining loss resulting from dielectric loss, air radiation, and substrate loss. Intensity and frequency characteristics of magnetic loss can be modified by changes to the embedded magnetic material. Material properties such as saturation magnetization, particle size, magnetic anisotropy, and particle shapes are the key parameters used to tailor the absorbing performance.

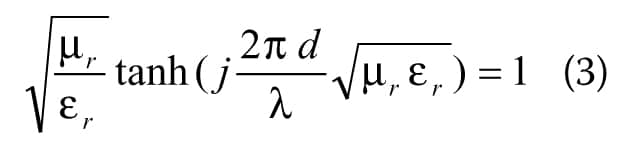

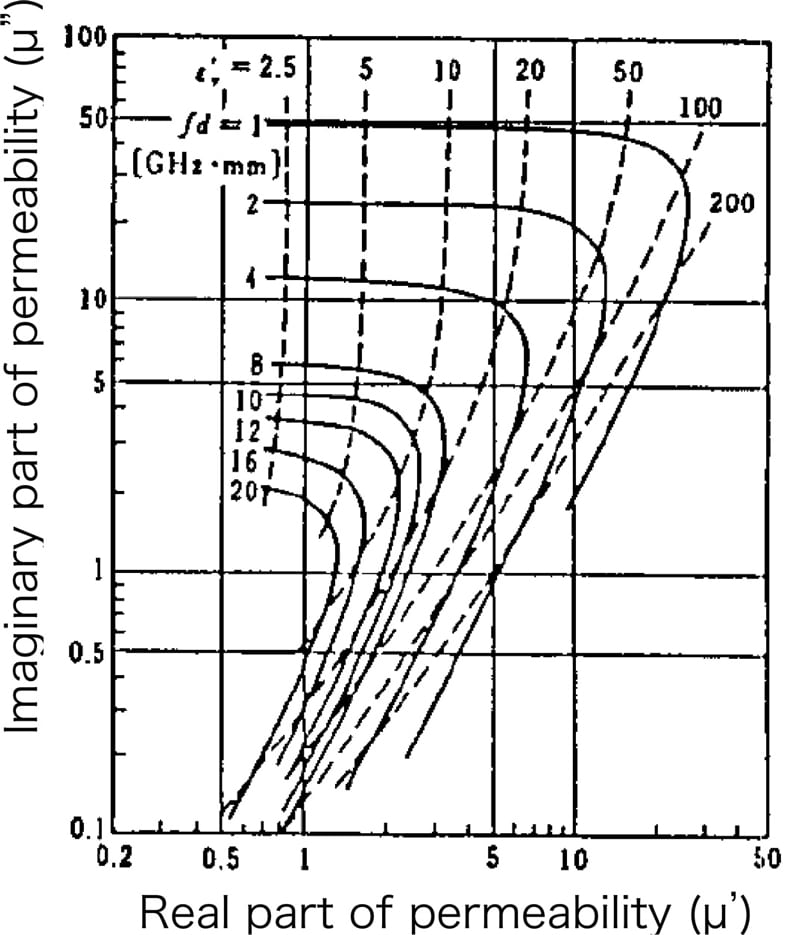

In the far-field application, the reflected loss of the composite absorber is determined by the wave impedance matching technique. For a microwave absorbing layer terminated by a high conductive material, the equation for wave impedance with zero reflection can be expressed by the following equation, where μr and εr are the complex permeability and permittivity, d is the thickness of the sheet absorber, and λ is the wavelength in free space.[4]

The combined effect of incident wave and reflected wave can be compensated for at the sheet surface. Figure 4 shows the frequency-thickness (fd) contours satisfying the above equation. Theoretically, perfect electromagnetic wave absorption happens where the complex permeability equals the complex permittivity. Still, composite absorbers have an inhomogeneous structure, which typically results in a dispersed frequency pattern with a dominant center frequency. Electromagnetic wave absorbers with high magnetic permeability and dielectric constant values can be optimized to attenuate over a specific desired frequency band.

APPLICATION EXAMPLES:

Attached Directly on Noisy Components

One of the most common approaches in the EMI debugging process is to find the second and third harmonics stemming from a specific clock frequency. Attaching a die-cut composite absorbing sheet to the noisy component can significantly attenuate the noise level (Figure 5). In this case, the composite absorbing sheet works by increasing impedance and thus reducing the coupled noise. Generally, an absorber sheet has high intrinsic electrical resistivity so electrical shorts do not occur even when the absorber is attached directly to the lead wire. Absorbers are most frequently applied to high-speed CPUs and video signal processors, memory chips, and oscillator chips in electronic systems.

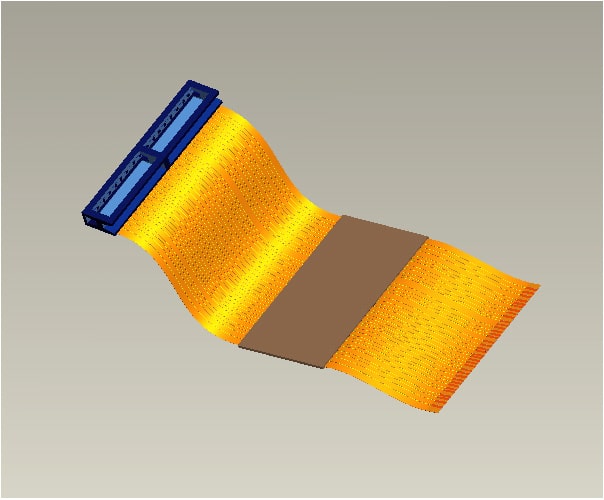

Wrapped Around the Interconnecting Field Programmable Circuit Board (FPCB) Cable

When debugging an interference problem, designers often focus their attention primarily on critical components. Meanwhile, the system FPCB cable that interconnects each of the components is frequently overlooked. Often, a FPCB cable exhibits noise coupled between the signal lines, picks up noise from other sources, and emits noise to other areas traversed by the interconnection. Sometimes, the FPCB acts as a noise-radiating antenna within the system. EMC ferrites, with their high magnetic permeability and ferromagnetic resonance characteristics, are a cost-effective material as an inductor and common mode noise filter. Composite absorber sheets have very similar EMI characteristics to EMC ferrites (Figure 6). However, while ferrite cores are bulky and rigid, composite absorber sheets are thin and flexible. Consequently, these sheets can be installed easily in a very compact enclosure without the need to change the PCB layout. The impedance composite absorber sheets often are a more practical solution than ferrites in reducing high frequency noise because of their relatively lower magnetic permeability and smaller effective volume.

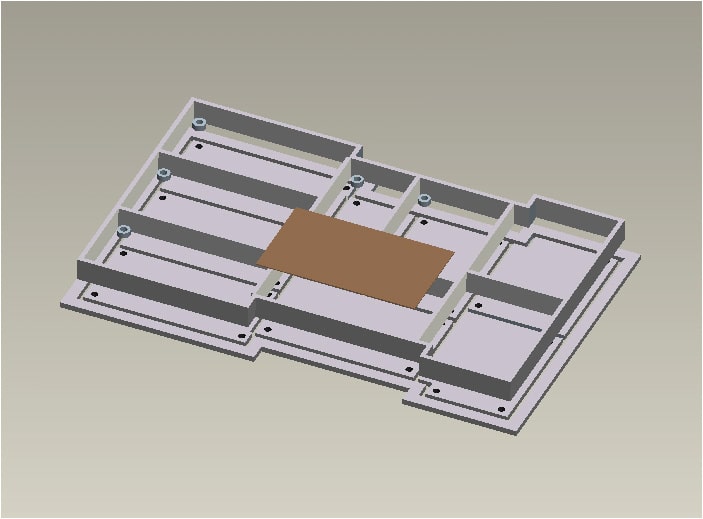

Applied to the Inside of a Shielded Can

The preferred way to design out crosstalk is to isolate components and circuits with different frequencies on the same circuit board. Unfortunately, in the newer miniaturized and densely packaged mobile communication equipment, it is almost impossible to separate circuits for each frequency band. Also, electromagnetic waves can reflect repeatedly off the shield wall, causing transmission interference and, ultimately, poor performance. In these cases, a shield by itself cannot provide a sufficiently effective solution for the system. However, attaching an absorber sheet on the wall of the shield can reinforce the effectiveness of can shielding (Figure 7). This absorber sheet soaks up the electromagnetic wave energy, converting it to an imperceptible degree of heat. This technique is also beneficial for the cavity resonance of the shield can and the small opening between the RF block wall and the PCB.

Attaching an appropriate absorber sheet on the shield can or conductive body results in a wave impedance matching condition as mentioned in Equation 3. In such an instance, this surface can attenuate the electromagnetic noise of a specific frequency. For example, the signal sensitivity of a GPS system using a 1.574-GHz satellite signal can be improved by attaching an impedance matching absorber with a controlled thickness.

Enhanced the Electrostatic Discharge (ESD) Control

System corruption from ESD can occur via two modes: actual contact and air discharge. High-frequency electrical current is generated during the discharge, resulting in both direct and secondary radiated noise within the system. Composite absorbing sheets are also effective for suppressing external noise generated by ESD. For example, a high-speed microprocessor surrounded by a conductive chassis can be the victim of radiated noise generated from the current loop passing through the adjacent body. In this case, the composite absorbing sheet not only attenuates self-radiated noise from the microprocessor, but also protects the microprocessor from the external noise caused by ESD.

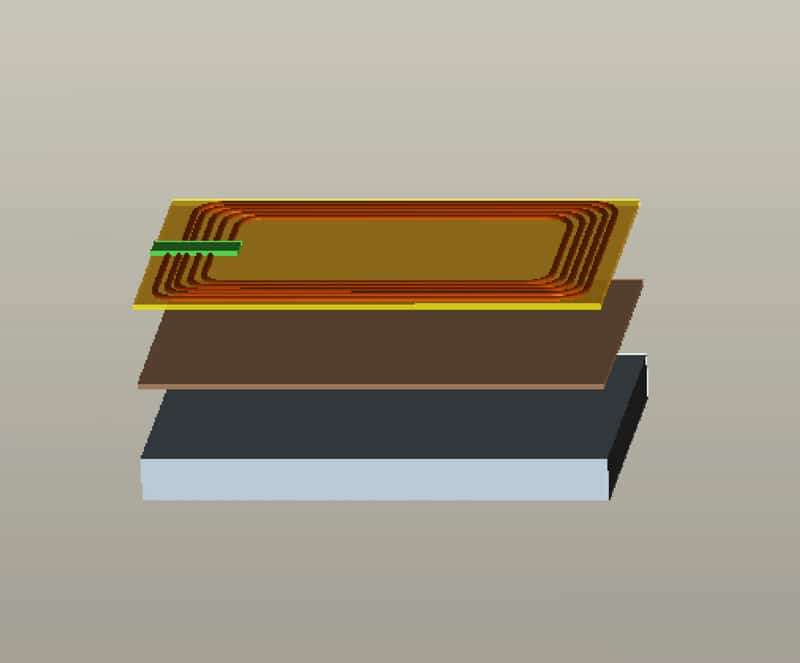

Protected from Magnetic Fields

A magnetic shield works by changing the direction of magnetic flux. The shield is achieved by placing a high magnetic permeability material between the field source and victim component. A Hall sensor and other magnetic field sensitive components can be protected easily with high permeability material, such as a composite absorber sheet. In general, the higher permeability materials give more shielding effectiveness, but their effective frequency range is inversely proportional to permeability value.

Composite noise absorber sheets have lower magnetic permeability value than soft magnetic alloy sheets, but they are still an effective magnetic shield up to the range of several tens of MHz. An application of an absorber sheet in conjunction with a 13.56-MHz RFID tag illustrates the value of the absorber. This RFID system uses magnetic coupling for communication between the reader and the tag. When the tag is attached on the metal surface, the diamagnetic field between the tag and metal object can interrupt the communication between the tag and reader. When a composite absorber is inserted between the tag and metal, the magnetic field radiated from the tag is unimpaired by the metal and the RFID tag works with the reader. (Figure 8 )

CONCLUSION

This paper describes the theoretical background and application examples of composite noise absorbers. As detailed above, composite absorber sheets can solve a variety of EMI issues without costly modification to PCB layout or equipment re-design. Considering the pressures to reduce development time and to speed products to market, this product can provide innovative solutions for many electronic design engineers. Also, it allows manufacturers to meet the varying demands of EMC regulations or standards that differ from market to market. Absorber materials as described here are a new, viable means for controlling EMI noise that set them apart from conventional shielding methods.

REFERENCES

1. Snelling, E.C. Soft Ferrites, 2nd edition. London: Butterworth, 1988.

2. Boerekamp, J.G. and Visser, E.G. “Grain size dependency of the Steinmetz coefficient of soft ferrite power losses,” Journal de physique 4, Vol. 7. (1997): pp. C-125-C126. Les Ulis, France: Editions de Physique.

3. Ono, H., Takase, Y., Yoshida, S., and Hashimoto, O. . “Analysis on noise suppression effect of the composite magnetic sheet for the use in near field,” in Proceedings of the IEEE International Symposium on EMC. Istanbul, Turkey, pp. 938-941, 2003.

4. Musal, H.M. and Smith, D.C. “Universal Design Chart for Specula Absorber,” International Magnetics Conference, 1-3 April, 1990.

JUNG-JU SUH, PH.D. is a senior engineer in the Electrical Markets Division of 3M Korea. Currently, he works in product development on EMC materials. In 2000 he received his Ph.D. in material science engineering from Sungkyunkwan University in Korea, where he specialized in soft magnetic materials such as ferrites. Prior to joining 3M in 2005, he was employed as a product development engineer at ISU, Inc., developing new EMC materials.