Many electronic designs need shielding materials that combine resistance to electromagnetic interference (EMI) with other application-specific requirements. For example, the EMI gaskets that are used in military touchscreens need to attenuate EMI emissions, provide electrical conductivity, and ensure environmental sealing. These shielding gaskets also must also cushion the unit from mechanical shock and be soft enough to avoid interfering with the display’s touch function.

The EMI shielding that’s used in automotive, aerospace, and medical electronics must also meet multiple requirements. For example, an EMI gasket that’s used with commercial aircraft may need to resist the splash of jet fuel or cleaning agents. EMI gaskets that are used in medical devices must combine required levels of shielding with corrosion resistance. Shielding that’s used with electric vehicle (EV) charging stations or robotics may require compliance with UL 94 standards for flammability.

For electronic designers, EMI shielding decisions can be complex. Particle-filled silicones are used in many demanding applications, but can they meet all of your application’s requirements? Are EMI gaskets made of these materials cost-effective, and do particle-filled silicones support design for manufacturability?

Understanding Particle-Filled Silicones

Particle-filled silicones are elastomeric compounds that combine the advantages of silicone rubber with the electrical properties of metals. An inert, synthetic elastomer, silicone offers thermal stability over a wide temperature range along with resistance to ozone, water, and sunlight. When filled with tiny metal or metal-coated particles, silicone compounds combine EMI shielding and electrical conductivity with environmental sealing.

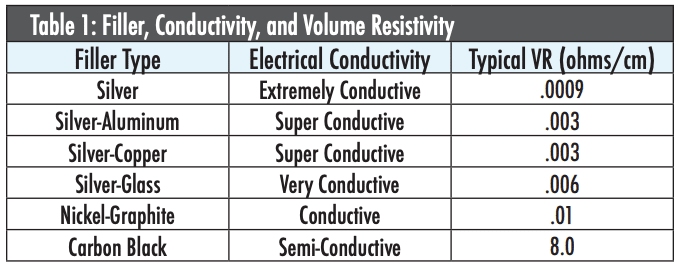

Table 1 shows the relationship between filler type, conductivity, and typical volume resistivity (VR) as measured in ohms per centimeter. Direct methods for measuring shielding effectiveness can be expensive and complex, so VR is a commonly used method for indicating EMI shielding effectiveness indirectly. Note the fill types for particle-filled silicones include pure silver, silver-plated materials, and nickel-coated fills.

Electrical Conductivity, Material Properties, and Cost

Silicones have many desirable properties, but loading them with a high percentage of metal particles to increase electrical conductivity can have negative tradeoffs. That’s why historically; some designers have rejected particle-filled silicones as too hard or too brittle. Other designers have complained about part size limitations based on mold dimensions and long lead times for sheet materials. Some industry professionals also believe (incorrectly) that all particle-filled silicones are too thick to support thinner electronic designs.

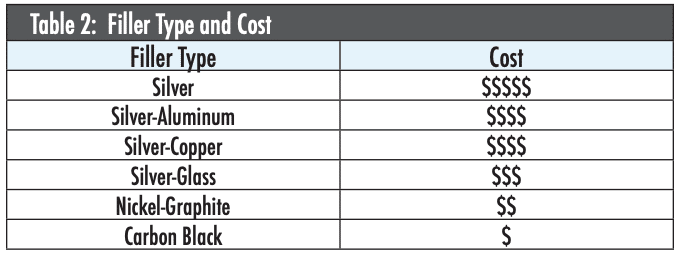

The cost of older, particle-filled products also discouraged their use. For years, the filler of choice for shielding silicones was silver-aluminum. The U.S. military’s development of the MIL-DTL-83528 specification played an important role in this particle’s popularity. When silver began approaching $50 per Troy ounce in 2011, however, the fact that these elastomers were specified on thousands of gasket drawings and prints became problematic. EMI gaskets made of silicones filled were pure silver were even more expensive.

Today’s electronic designers can specify alternative particle fills. As Table 2 shows, choices such as nickel-graphite cost significantly less. Note the difference in cost between silver, silver-aluminum, and nickel-graphite fills.

Nickel-Graphite Silicones

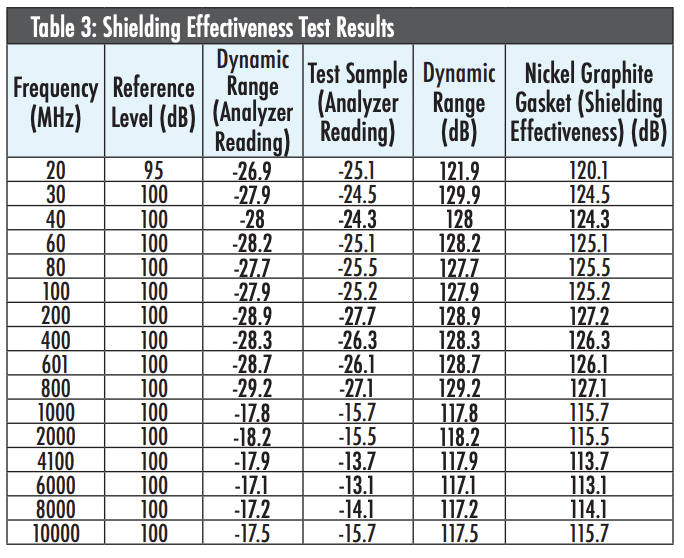

Manufacturers, including Specialty Silicone Products (SSP), now supply cost-effective nickel-graphite silicones that perform at the shielding levels of silver-aluminum filled products. Table 3 contains results from a third-party test report. It shows how SSP’s nickel-graphite silicones meet the shielding effectiveness requirements of MIL-DTL-83528, which sets a minimum shielding effectiveness of 100 dB.

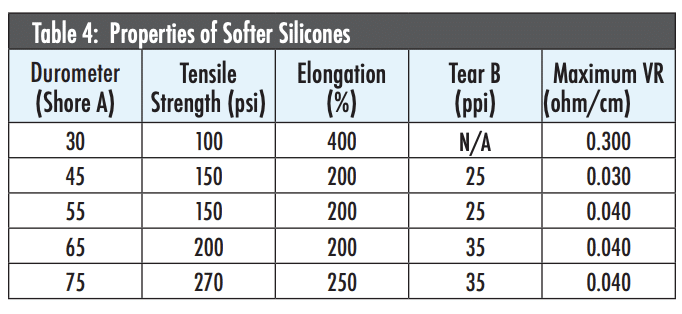

Particle-filled silicones also provide other desirable material properties. For example, as Table 4 shows, SSP 502-series SpecShield™ silicones include lower-durometer (softer) materials with good tensile strength, elongation, and tear resistance along with maximum VR levels. Durometer, a measure of harness or softness, is an important engineering property because it affects the flexibility and compressibility of an EMI gasket. With particle-filled silicones, the Shore A scale for durometer is used.

Conductive silicone gaskets can also resist salt spray and corrosion according to ASTM B 117:2003 requirements. This is an important consideration for EMI gaskets that are used in marine environments.

Silver-Aluminum and Other Silver-Filled Silicones

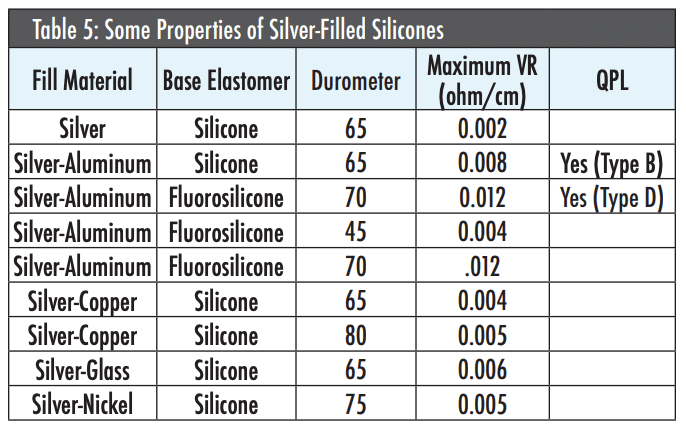

If necessary, electronic designers can still choose silver and silver-filled elastomers in various durometers based on their application requirements. Table 5 lists properties for silver and silver-filled elastomers, such as SpecShield™ materials that meet the requirements of MIL-DTL-83528. Included are two silver-aluminum products from SSP with a qualified product listing (QPL) from the Defense Logistics Agency (DLA), part of the U.S. Department of Defense.

Some silver-filled elastomers use fluorosilicone as the base material. Fluorosilicones such as the silver-aluminum products in Table 5 have physical and mechanical properties that are very similar to standard silicones; however, fluorosilicones also provide improved resistance to fuels, oils, and solvents.

Overcoming Design and Manufacturing Challenges

Thanks to innovations in silicone compounding, particle-filled elastomers can meet demanding shielding requirements along with other project specifications. For example, because nickel-graphite silicones such as SpecShield™ elastomers are available in 30, 40, and 45 durometer (Shore A), they’re soft enough for enclosure gaskets. Other, higher-durometer shielding elastomers that use fluorosilicone as the base elastomer can resist fuels and chemicals. These fluorosilicone compounds come in 50, 60, and 80 durometers (Shore A) for applications that require EMI gaskets made of harder materials.

Unlike older shielding elastomers, newer shielding materials such as SpecShield™ products contain enough metal filler to ensure effective EMI shielding and electrical conductivity. These material are also support the cost-effective fabrication of EMI gaskets. As the only supplier of shielding elastomers that offers solid, heatcured EMI silicones in continuous rolls, SSP can supply nickel-graphite silicones in higher durometers for applications that require harder materials. Compared to molded sheets, continuous rolls promote optimum yields for cost-effective conversion. Continuous rolls also support the use of automated equipment instead of time-consuming manual operations.

Various higher-durometer, nickel-graphite silicones are available, but some EMI gasket applications require reinforcement for added strength. For example, SSP’s ArmourRFI™ is a 65-durometer SpecShield™ elastomer that’s reinforced with an internal nickel-coated mesh. Lower-durometer, nickel-graphite silicones can also be reinforced with an inner layer of conductive fabric for added conductivity and material strength, which helps to prevent brittleness and tearing during EMI gasket fabrication.

During gasket cutting, particle-filled silicones won’t stretch or become deformed. Connector holes align properly, and the material’s structural properties support greater tear resistance – an important consideration for thinner wall gaskets. Product designers can also specify the use of an adhesive backing for ease-of-installation. For shielding applications where Z-axis conductivity is required, particle-filled silicones can support the use of electrically conductive adhesives.

Conclusion

Particle-filled silicones are good choice for meeting EMI shielding and many other application requirements. Electronic designers can choose from various types of filled elastomers, but it’s important to account for all of your project requirements – including cost and manufacturability. As silicone shielding elastomers are used in a growing number of military and commercial applications, designers can expect continued advancements in nickel-graphite and silver-aluminum materials.