IEC 61000-4-3: 2006’s frequency escalation

Jason Smith and Pat Malloy

AR RF/Microwave Instrumentation, Souderton, PA, USA

An increasing number of new and proposed EMC standards are pushing the upper frequency test limits higher into the microwave spectrum. The latest EMC standard released, IEC 61000-4-3: 2006, is no exception. The upper frequency test limit has been increased from 2.5 GHz to 6 GHz to reflect the increased use of the microwave spectrum, primarily by wireless communication devices. While the standard is written to take into account some of the present threats to equipment, regrettably, it does not cover all potential threats.

With the world’s ever growing hunger for more sophisticated communication and control devices, it’s a sure bet that more of the microwave spectrum will be used to accommodate new electronic products in the near future. In addition to this “frequency creep” issue, EMC standards fail to take into account the possibility of transmitters operating in close proximity that can produce RF fields considerably greater than those mandated in the standard.

From a manufacturer’s perspective, it is prudent to consider these “worst case” scenarios involving higher test frequencies and test levels to insure quality assurance and reliability, and ultimately, to maintain customer satisfaction and loyalty. The alternative of testing just to the required specifications may provide an initial cost savings, but in the long run can prove disastrous if a customer discovers problems with product that just “squeaked” through a minimal EMC testing protocol.

INTERFERENCE TESTING

In radiated immunity testing, products must withstand a given electromagnetic energy field while maintaining an acceptable degree of performance. The electromagnetic field used in testing represents the possible interference that the equipment-under-test (EUT) may be exposed to in normal use. There are numerous sources of possible RF interference. These include electronic digital devices operated nearby, some with clock frequencies exceeding 2 GHz. Other likely “culprits” are transmitters such as walkie-talkies, mobile phones, WiFi, WiMAX, and Bluetooth, as well as commonplace electric motors and generators.

HISTORY OF IEC 61000-4-3

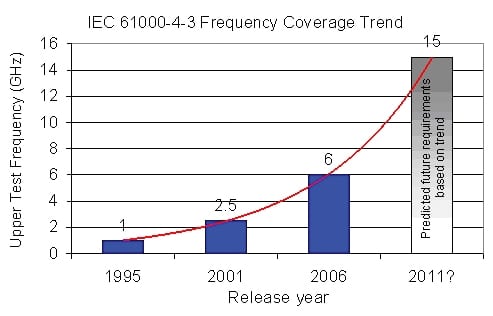

As the nature of electronic products has changed over the years, immunity standards have changed to reflect the ever increasing complexity of electronic gear. For example, increasing clock speeds and transmission frequencies have forced the International Electrotechnical Commission (IEC) to test for immunity at frequencies unheard of a decade ago. Note the progression in the upper frequency test limit (frequency creep) in the various editions of the primary commercial immunity standard shown below:

- IEC 1000-4-3:1995—Original release coverage of 80 MHz to 1 GHz

- IEC 61000-4-3:2001—Released with frequency coverage 80 MHz to 2.5 GHz

- IEC 61000-4-3:2006—Released with frequency coverage 80 MHz to 6 GHz

The graph in Figure 1 clearly shows the increasing test frequency trend. The next release of IEC 61000-4-3 is scheduled for 2011; and if the past is any prediction of future requirements, it is apparent that the test frequency will possibly be in the 15-GHz region.

THE UPWARD TREND

Wireless digital communications now cover frequency ranges up to 6 GHz. Annex G of IEC 61000-4-3: 2006 lists some of the common transmission standards used throughout the world today and clearly shows operating frequencies approaching 6 GHz. The standard does not consider all RF interference sources (Table 1), nor does it include new emerging technologies.

WIRELESS FREQUENCY COVERAGE

Most industrial countries regulate use of the RF spectrum and have mapped out allocations for frequency usage up to 300 GHz. Given our insatiable need for more frequency bandwidth, it’s just a matter of time before additional chunks of bandwidth are licensed not only for emerging wireless applications, but for yet unimagined systems of the future.

In addition, radar used for commercial aircraft, military, naval vessels, and police operates at frequencies up to, and in some cases, exceeding 60 GHz.

FINDING AN ACCEPTABLE SOLUTION

It is important to change the mind set from the minimal requirements a product needs to meet as mandated by adherence to the current EMC test standard, to creating optimal product quality and safety—and, therefore, customer satisfaction. Keep in mind that EMC standards are always going to be lagging the actual frequencies in use because the IEC can include only transmitting technologies that are available at the time of the standards release. In addition, they do not take into account extreme cases in which the transmitter may be in close proximity resulting in RF fields exceeding the maximum test levels called out in the standard. Since the IEC cannot predict how technology evolves, by necessity, the standard is designed to be a minimum base line for testing.

While some electronic products can benefit from applying a “minimum base line test” philosophy, products that are of a critical nature must be held to a much higher acceptance level. For example, if one is manufacturing collision avoidance systems for military or commercial aircraft or automotive ABS systems, minimal EMC testing is not advisable.

Over-testing is not a particularly new concept. Many manufacturers of so called non-critical products have for years tested at twice the required test voltage to insure EMC compliance. Given the existing rush to push further into the microwave spectrum, it is now practical to “push” the upper test frequency past that required in the standard.

How should one proceed to set up a viable test protocol? One extreme path to cover all your bases would be to test to a “worst case scenario.” This option requires that all possible RF/microwave sources be identified, along with their maximum power levels and operating frequencies. Then one must apply an acceptable safety margin to both field level and frequency range to cover variations and the unexpected. Still, adopting the worst case scenario philosophy when testing is not only a daunting task, but a very expensive one as well.

A more reasonable solution would be the adoption of a “design to meet” criteria throughout product development. The goal of this design philosophy would be to achieve an inherent degree of “ruggedness” in the basic product design. This approach involves the application of a modest increase in safety margins to all the required EMC test levels. For example, a requirement of 3 V/m at a frequency of 10 GHz could translate into a test conducted at 10 V/m up to 20 GHz.

When a product conforms to an EMC test that applies these extended levels, the margin built into the product insures a high level of quality and reliability and also ensures a level of technical quality that boosts customer confidence and protects market share. Keep in mind that while the current issue of the commercial IEC EMC standard mandates relatively modest test levels up to a maximum frequency of 6 GHz, other segments of the marketplace are already operating and testing at 18 to 40 GHz on a routine basis.

CONCLUSION

In summary, ever changing applications requiring additional microwave spectrum are best handled by a testing philosophy that applies a reasonable amount of “over-testing” that involves the extension of not only voltage levels (an time-honored practice), but also an extension in the upper test frequency. By gearing up now to test to higher frequencies, a manufacturer will be positioned to deal with the inevitable increase when the next EMC standard is released. As a result of applying larger safety margins in EMC testing, one can provide products that stand the test of time and stand up to the quality customers expect and deserve.

Jason Smith is Sr. Sales Applications Engineer for AR RF/Microwave Instrumentation. His responsibilities include product applications support to customers, technical training, technical writing, and guidance for product development. He has over seven years’ EMC experience as a lab manager and test engineer for independent EMC test labs. He has experience testing to IEC, MIL-STD, DO160, Medical, Telecom, and Automotive requirements. Jason can be reached at 215-723-8181, [email protected].

Pat Malloy worked in Application Engineering at AR RF/Microwave Instrumentation for fifteen years. He retired in 2004 as a Senior Applications Engineer. Prior work experience includes sixteen years as a Senior Sales Engineer at Tektronix, Inc., seven years in an engineering group at AT& T Bell Laboratories, and four years as a Guided Missile Technician in the U.S. Navy. He was graduated from Lafayette College in 1972 with a bachelor’s degree in electrical engineering. Pat can be reached at [email protected].