Consumer demand for more entertainment, safety, and communication options within automobiles has significantly increased both the density of electronic components and the number of on-board wired and wireless signals. The result: an ever-expanding range of signals contained within the same car-sized fixed space.

USING AN OSCILLOSCOPE TO VERIFY EMC TESTS FOR AUTOMOTIVE ELECTRONICS

It’s important for electronic components used within automobiles to be robust and to function correctly in a real-world environment increasingly filled with electromagnetic (EM) waves originating from cell phones, Bluetooth headsets, satellite radio, AM/FM radio, wireless internet, RADAR, and countless other potential sources of electromagnetic interference (EMI). Ensuring robustness means meeting rigorous EMI immunity standards within a controlled environment. Electronic Control Units (ECUs) under test typically must comply with strict ISO (International Organization for Standardization) guidelines and with requirements negotiated between the automobile manufacturer and the ECU component supplier.

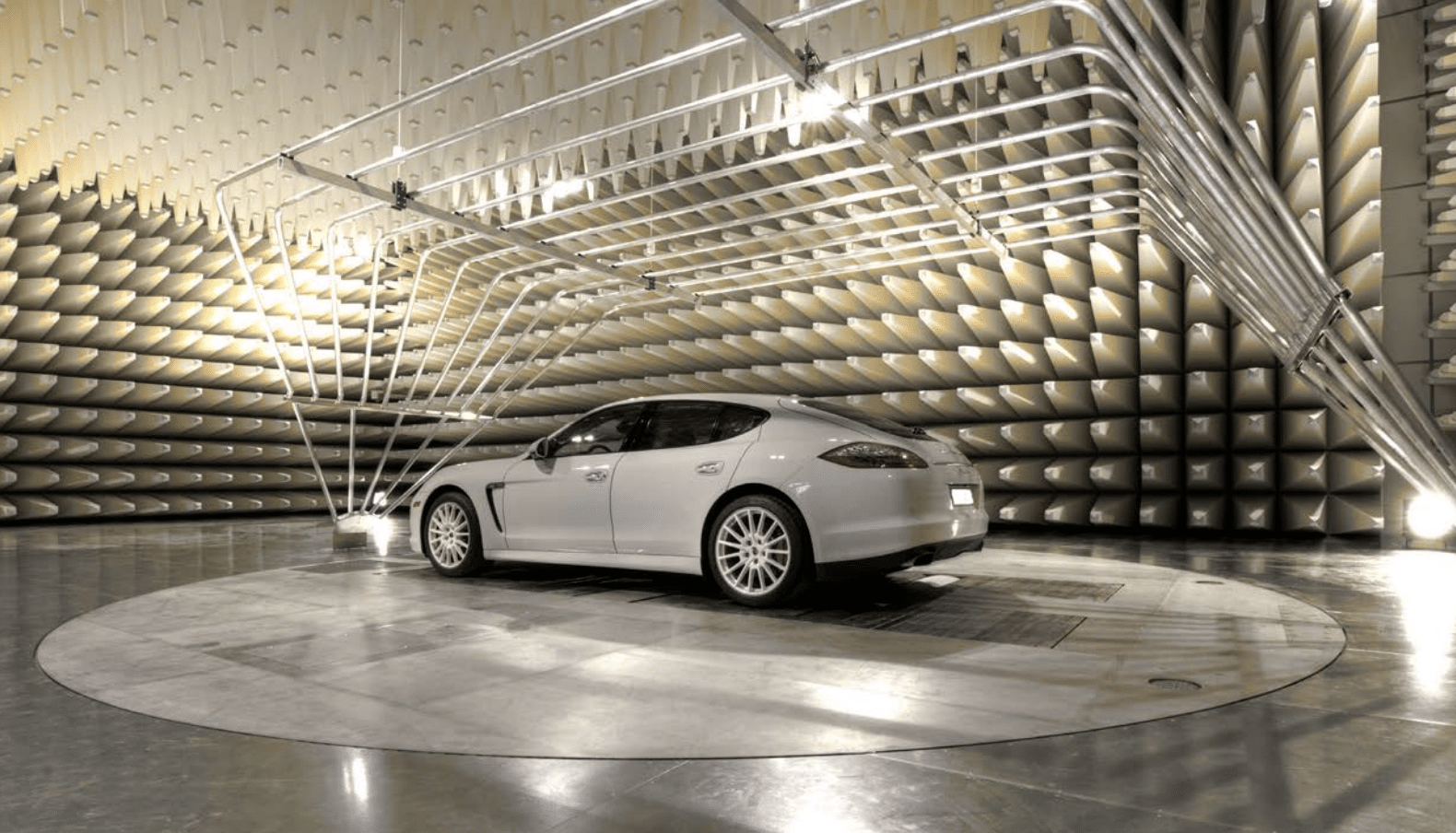

As an example of typical frequencies and field strengths seen during testing, consider the radiated RF immunity test described in ISO/IEC 61000-4-21. The test utilizes a reverberant chamber containing a mechanical-mode tuner. When a sufficient number of tuner positions have been obtained at a given test frequency, the tuner produces a statistically uniform field within the useable volume of the chamber with test frequencies ranging from 0.4 to 3 GHz and field strengths as high as 200 V/m (CW and AM) and 600 V/m (radar pulses). Field strengths in such test environments are too high, both for electronic test equipment to monitor the signals, and for test personnel to be safely within the reverberent chamber. Thus, measurement instruments and test personnel remain outside of the sealed chamber. Fiber-optic transmitter and receiver units and fiber optic cables transport the signal from the ECU inside of the chamber to the test equipment outside of the chamber.

Figure 1 shows a real-world test configuration for deviation detection in immunity testing, photographed from inside the sealed chamber (while the transmitting antenna was powered off). Note that the mode tuner is shown to the right of the chamber. The left side of the chamber has CAN bus fiber-optic transmitters placed on a foam bench having a relative permittivity of < 1.4 and located within the usable volume of the reverberant chamber. The fiber-optic transmitters optically convert the output signals from the ECU under test. The signals are transported through the chamber by means of RF-hardened fiber-optic cables that exit the chamber near the floorboard via waveguides.

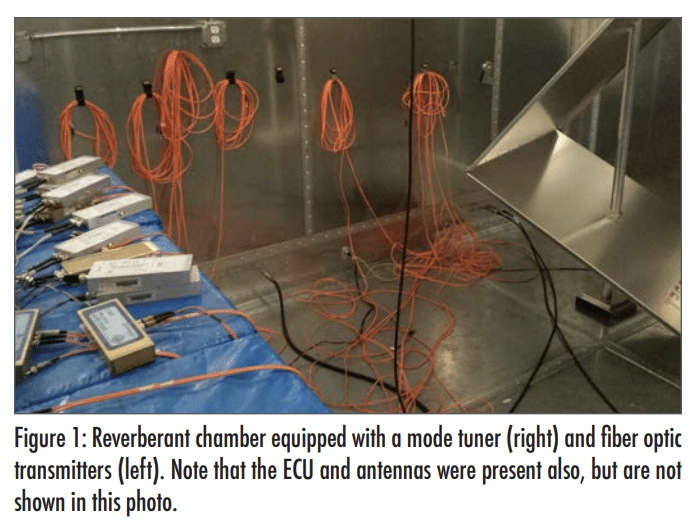

In addition to immunity to EMI, automotive electronic components are designed to have a certain level of immunity to ESD. Test levels for ESD immunity range from 2 kV to 25 kV. Voltage is typically applied in steps until it reaches an established limit. Before an ESD simulator is applied to the ECU under test, it must first be calibrated using an oscilloscope. Figure 2 shows an ESD simulator gun applying a contact discharge into a current shunt target that is connected to the oscilloscope’s 50Ω DC-coupled input via a double-shielded cable and inline attenuators.

Verifying the ESD simulator includes characterizing the discharge pulse waveform. The second edition of ISO 10605 identifies rise time, first peak current, current at t1, and current at t2 as the parameters of interest. The values of t1 and t2 vary with the value of R and C in a given RC network for the purpose of verifying its time constant. An oscilloscope rapidly and automatically characterizes each of these measurement parameters.

Another important measurement requirement for automotive electronics is the Electrical Fast Transient (EFT), a phenomenon in which current flow is instantaneously interrupted, resulting in arcing between contacts. Common causes for EFT can include relay-contact bounce, opening and closing of circuit breakers, switching of inductive loads, and powering down equipment. Breakdown of the air gap between electrical contacts often triggers a rapid burst of EFT pulses. The sudden sequence of energy bursts from EFT pulses can couple into nearby electrical paths, risking digital signal corruption of automotive electronic systems and ensuing potential malfunctions. Therefore, electronic products must be tested to ensure safe operation in the presence of EFT events.

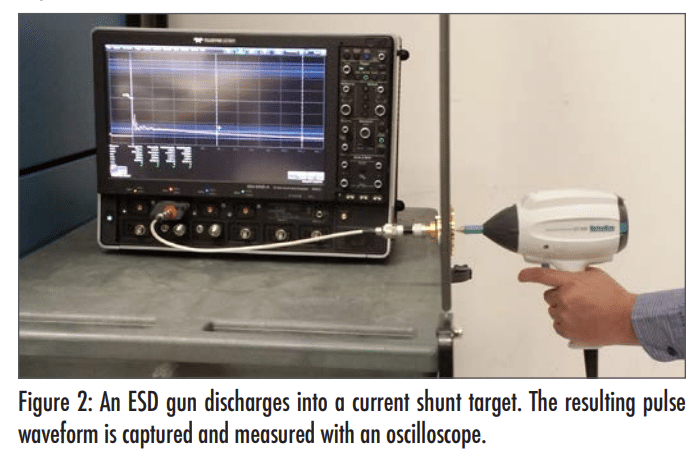

Figure 3 depicts a series of EFT bursts acquired as segments using an oscilloscope’s sequential capture mode. Note that the long gap time between bursts has been removed by the process of sequential capture, leaving only the desired burst waveform within the acquisition.

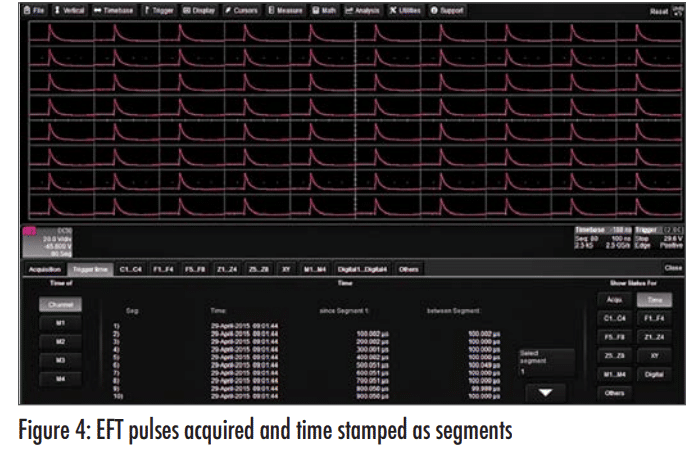

In contrast, Figure 4 shows EFT pulses, rather than bursts, acquired as segments.

Potentially tens of thousands of individual pulses could be acquired. Note that the time scaling for sequential burst capture here is 2 ms per division (corresponding to a 20-ms time capture window), while the time scaling for sequential pulse capture is 100 ns per division (corresponding to a 1-ms time capture window).

The intersegment time stamps in EFT burst capture mode shows an inter-burst timing of approximately 100 ms between bursts, while the intersegment time stamps in EFT pulse capture mode shows an inter-pulse timing of approximately 100 ms between pulses. The time scaling between the two captures differs by a factor of 1000x, highlighting the contrast between the characterizations of either individual EFT pulses or EFT bursts.

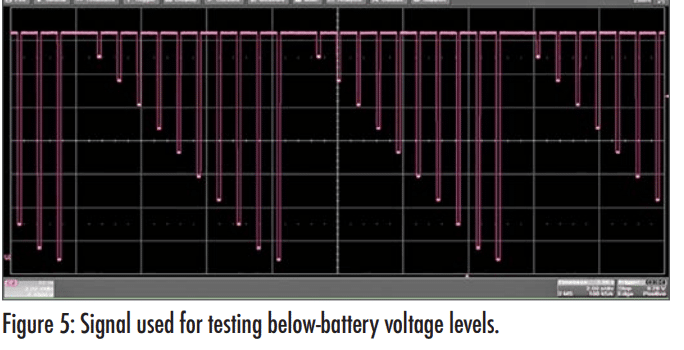

A final consideration is voltage drop and interruption testing. To verify that devices will operate properly in the presence of a voltage supply interruption, electronics must be tested for voltage dips (defined as a sudden reduction in voltage followed by recovery to the original voltage), short interruptions (defined as a complete absence of supply voltage for a short period of time followed by a recovery to the original voltage), and voltage variations (defined as gradual changes of the supply voltage to a higher or lower voltage value than the rated voltage).

To ensure that the signal generator outputs the intended conditions to simulate these effects, the signal generator waveform characteristics must be validated with an oscilloscope before connecting the generator to the electronic units under test.

Figure 5 shows an example (abbreviated) waveform from the standard ISO 16750-2. This waveform shape is used to verify the reset behavior of devices with reset functionality (such as microcontrollers) at different voltage drops. Note that the waveform begins at 13.55 V. In the first dip, the voltage level drops approximately 10.6% to 12.12 V where it dwells for 105 ms, then the level returns to its original 13.55-V battery level. One half second later, the second dip lowers the voltage level 21.2% to 10.68 V, where it dwells for 105 ms before returning to the original 13.55 V. This process of decrementing the voltage-dip level and returning to source voltage continues at fixed intervals until the level reaches zero volts.

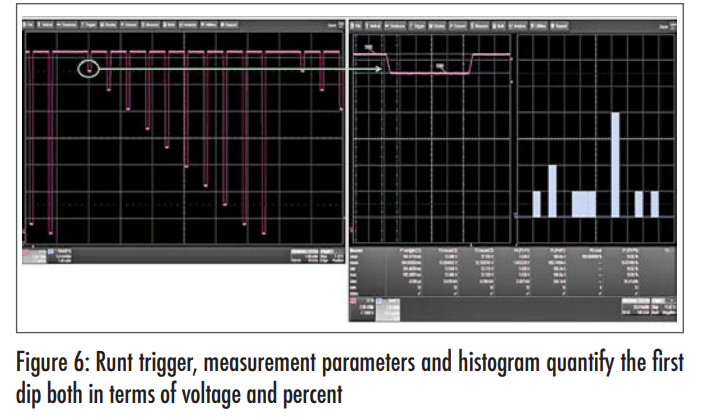

Testing the time duration and voltage level reduction of each dip is a time-consuming and error-prone task when relying on a live operator to measure using cursors from a single waveform capture. Not only do cursors rely on the operator’s hand-eye coordination, but they are also specified to yield a 2% measurement inaccuracy. In addition, significant time is lost as an operator manually places each cursor at the correct time and voltage level. Lastly, the results will cover only a single acquisition, which by definition does not provide statistical significance.

Figure 6 shows a measurement method that resolves each of the problems listed above. With this method, we use a negative going runt trigger to isolate a specific dip level. A runt trigger is a hardware trigger selection in which the waveform must first pass through one threshold, but not cross through a second threshold, to meet the trigger criteria. By selecting the runt polarity to be negative going, the trigger circuit isolates a voltage dip, which meets the criteria. Because the trigger circuit can lock onto this specific dip level each time it occurs, the oscilloscope rapidly accumulates measurement statistics. In Figure 6, the trigger circuit has locked onto the first dip. With display persistence turned on, one can see that the first dip is the only dip acquired by the oscilloscope (Figure 6, right, pink). A histogram further displays quantified results with statistical significance. In this case, the histogram plots the distribution of pulse width along the X-axis, with the number of occurrences of each width displayed on the Y-axis (Figure 2, right, blue). Statistics showing measurement results are tallied in the measurement parameter table (Figure 6, right, bottom).

Automotive EMI and ESD testing involves many forms of testing. Oscilloscopes are well equipped to perform the rapid parametric measurements required for EMC immunity testing as well as calibration of an ESD simulation simulator. Using a fast-segmented acquisition mode, both electrical fast transient pulses and bursts can be captured and characterized. New techniques have been developed for validating the setup for voltage drop tests, providing rapid and accurate characterization.

Note: Photographs and images used in this article appear courtesy of Hitachi Automotive Systems, Farmington Hills, MI (an ISO-accredited lab).

Mike Hertz may be reached at; Mike.Hertz@teledynelecroy.com

David Maliniak may be reached at; David.Maliniak@Teledyne.com