Continuous efforts are needed to maintain a consistently repeatable test

Jason Smith, AR Worldwide Souderton, PA

The IEC 61000-4-3 standard on radiated electromagnetic field immunity has long been used in order to satisfy one key criterion of the European Union’s requirements for obtaining the CE mark. It is usually used in conjunction with a specific product test standard that includes detailed requirements for regulatory compliance. Such a product standard may provide additional guidance on testing, including test level severity and changes in procedure.

The object of this test standard is to establish a common reference for radiated RF immunity caused by any source. Electronic products need to be designed and tested for immunity to these sources. RF energy can radiate from many sources such as other electronic devices, electric motors and intentional transmitters such as walkie-talkies and cell phones. The introduction of more wireless devices in the past couple of years has increased the need for this testing not only to satisfy governmental requirements but also to increase product reliability and customer satisfaction.

Major Changes in IEC 61000-4-3 Edition 3.0

Some recent changes could have a big effect on some facilities and test equipment. These include:

- New Harmonic distortion requirement of test setup: better than 6 dBc.

- New Linearity check to make sure the RF amplifier is not operating in compression.

- New extension of frequency range up to 6 GHz.

- New test table material requirement.

HARMONIC DISTORTION

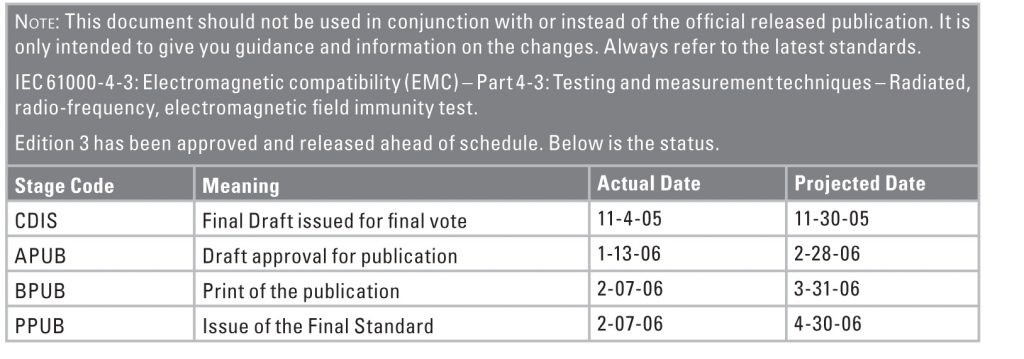

Harmonic distortion is the difference in dB between the fundamental and the harmonic of the fundamental. The new standard calls for a harmonic distortion of more than -6 dBc for the test setup. Consequently, all harmonics need to be 6 dB below the fundamental out of the transmitting antenna. This requirement could become a problem when using RF amplifiers in compression or when using Traveling Wave Tube (TWT) amplifiers. TWT amplifiers have been used historically for testing above 1 GHz when high power is required. They can offer significant cost/performance benefits at very high power levels. Since the introduction of solid-state amplifiers in this frequency range, many of the limitations of TWT amplifiers have been overcome. (At lower power levels, solid-state amplifiers are readily available.) TWT amplifiers can still be used for high field testing but care must be taken to satisfy the standard. Some TWT amplifiers combine tubes or switching-in filters for harmonic reduction. For most other TWT amplifiers, RF filters can be attached externally to block out these unwanted harmonics. Figure 1 shows an example of the harmonic content of a solid-state and a TWT amplifier (20 watt rated). The solid-state amplifier has an excellent level of -24 dBc while the TWT amplifier’s level is only -0.8 dBc.

The harmonic of the TWT will contribute to the calibration level since a broadband RF field probe is used, a device that cannot distinguish between a wanted and an unwanted signal. Also, antenna gain usually increases over its operating band. The antenna gain can be as much as 5 dB higher at the harmonic. In the above case, the -0.8-dBc harmonic distortion of the TWT will result in a much higher field level at the harmonic than at the fundamental. These harmonics will result in a significant error in field level. RF filters will be needed. The consequence of using filters will be some loss in power and productivity when switching these filters in and out. The amplifier used will dictate what frequency range(s) the filter will need to cover, or if multiple filters will be needed. Most solid-state amplifier will not need filtering.

High harmonic content can also have an unwanted adverse effect on the Equipment Under Test (EUT). The harmonic could occur at a frequency that causes the EUT to fail. Since the test personnel are testing at the fundamental frequency, they will mark this frequency as the failure which is not really the case. It is quite possible that this harmonic may be outside the intended test frequency range, and therefore should not even be part of the test. Obviously, dealing with unwanted harmonics and their potential for causing apparent failure of the EUT, is a paramount concern for EUT manufacturers.

By working backwards, a tester can estimate an acceptable amplifier harmonic content rating:

Max antenna gain between harmonic and fundamental = 5 dB

Other effects from setup and room (safety factor) = 3 dB

Required by spec = 6 dB

Total = 14 dB

Therefore, a harmonic content for the amplifiers better than -14 dBc will be more then acceptable.

This allows calculation for a safer harmonic content requirement for the amplifier, guaranteeing an acceptable harmonic level during testing. Also, the amplifier should not run into compression and filters should be used when necessary to achieve this safer harmonic content.

Linearity Check

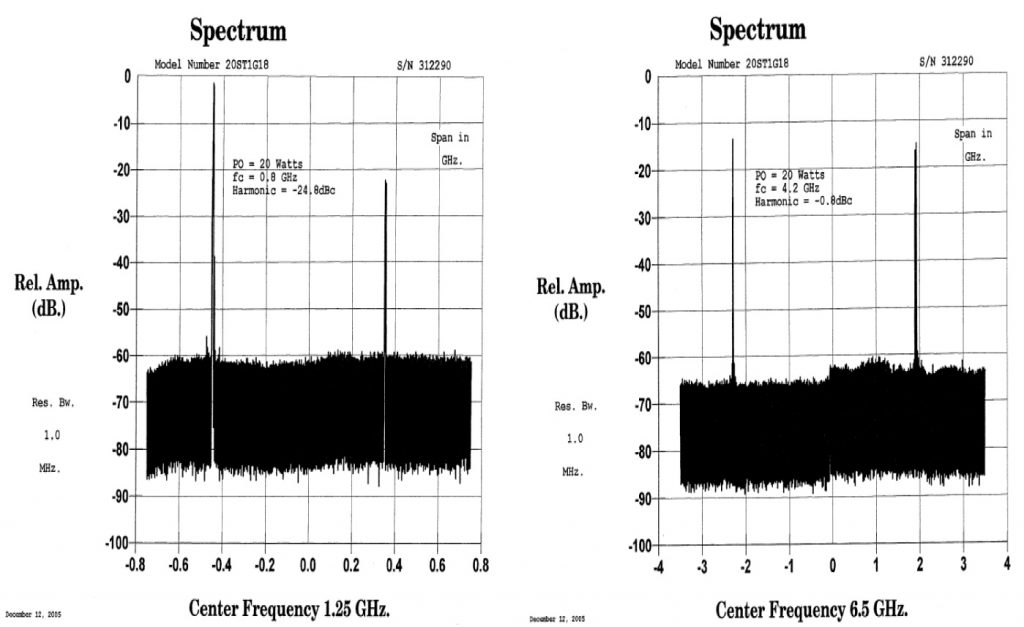

The linear region of an amplifier is the power range in which there is a 1:1 ratio in input (dB) change to output (dB) change. As the amplifier starts to saturate, this rating will alter. Solid-state amplifiers may be specified at both a 1-dB and a 3-dB compression point. Below the 1-dB compression point, the amplifiers response is referred to as linear. Above the 3-dB compression point, the amplifier is in full compression.

This distinction is important for two reasons. Firstly, if amplifiers are running in compression, the output signal will be distorted. For example, a sine wave will start to resemble a square wave. In the case of the IEC 61000-4-3, amplitude modulation (AM) will also be distorted possibly causing different unrepeatable test results. Secondly, when an amplifier is running closer to saturation, the harmonic content will increase.

Figure 2 shows one solid state amplifiers and the method for determining its 1-dB and 3-dB compression points. Basically, the point at which the input is increased by 10 dB but results in only a 9-dB change on the output will be the 1-dB compression point (Orange triangle). The point at which the input is increased by 10 dB but results in only a 7-dB change on the output is the 3-dB compression point (green triangle).

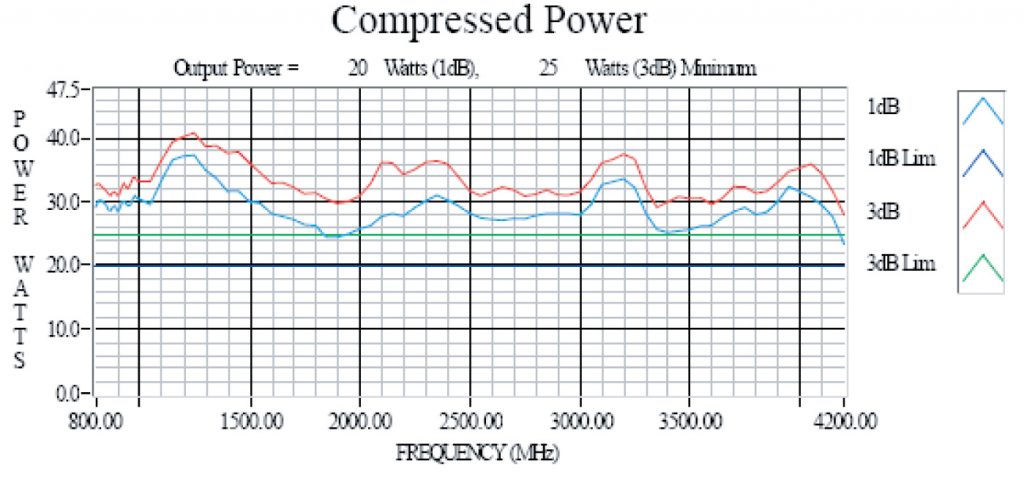

The new specification calls for a check for a 2-dB compression point (aqua triangle) while connected to the antenna. If the load (antenna) on the amplifier is a pure 50 Ω, then amplifier manufacturers could easily specify this new 2-dB compression point to be used as a reference when calculating test needs. Since any antenna which is used during testing is not a pure 50-Ω load but an unknown complex load, the compression point may very slightly. Thus, it is best to size amplifiers based on the manufacturer’s supplied 1-dB compression point to allow for some margin of error. This allowance could be a concern when using a TWT amplifier since they are normally not as linear as solid-state amplifiers. The 1-dB compression point is usually around 50% of its rated power; therefore, a 20-W TWT amplifier will have a 1-dB rating of about 10 W. In the case of the solid-state amplifier, it has a minimum output rating of 25 W. The minimum 1-dB compression rating is at about 20 W. Figure 3 shows production data of an amplifier. At 1.5 GHz it is producing 38 W with about a 1-dB compression rating of 30 W. It is always best to check the amplifier’s specification or to contact the manufacturer directly for this information and assistance with the selection of the product.

Increased Frequency Range

The frequency range increase from 2 GHz up to 6 GHz is a direct response to the use of more of the RF spectrum by the communication industries. In different countries and locations, the RF spectrum is being divided up depending on each country’s laws. So based on where the EUT is being used, not all frequency bands will need to be tested. In addition, not all communication standards use the same signal strengths. Because of these variations throughout the world, the new IEC 61000-4-3 leaves more precise definitions up to forthcoming product standards. These standards will specify what additional frequencies to cover in the communications bands: e.g., 800 to 960 MHz and 1.4 to 6 GHz. Product standards will also specify test levels which may not be consistent throughout the bands. The current 80 MHz to 1 GHz should remain the same.

Chamber setups may have to change because of this higher frequency requirement. Many labs have only a ferrite lined chamber. This works well when testing less than 1 GHz; but as frequency increases, it is difficult to meet the field uniformity requirements. The ferrite is not very absorbent above 1 GHz and will reflect the RF field. Annex C of IEC 61000-4-3 Ed. 3 explains this situation and gives good advice and options for correcting this problem. A fully lined anechoic chamber with ferrite and absorber material will work fine.

Test Table

The test table is now specified to be made of low permeable material. Rigid polystyrene is one material that is suggested. In the past many labs have used wood, which is fine when testing at lower frequencies. Now that testing can be as high as 6 GHz, wood will start to display some unwanted properties. High frequencies will reflect, making it difficult to meet the uniform field requirement. The reflections will also make test results less repeatable.

General Test Tips

These new requirements could require labs to upgrade and to purchase new equipment. Some helpful hints may increase the likelihood of success. If harmonic content is an issue:

- RF filters on the amplifier’s output may fix the problem.

- Make sure the additional losses of filters do not force the amplifier into saturation.

- Test time will increase as filters are switched in and out.

If working in saturation:

- Reduce all RF losses in the system.

- Use good low-loss RF cabling and connectors.

- Make sure all connections are torqued to specification.

- Make sure all connectors are clean.

- Shorten RF cabling (may require amplifier to be moved closer to the antenna).

- Use a different RF antenna.

- Higher gain antennas will require less power.

- Narrow beam width may not cover the full window of 1.5-m x 1.5-m uniform field calibration requirement. (See Appendix A for antenna coverage calculations.) Calibration to a smaller window is allowed above 1 GHz.

- Horn antennas will direct the energy forward better then Log antennas for better field performance.

- Move antenna in closer, no less than 1 meter.

Using the checklist above, a tester may still comply with the new requirements and may avoid the need for purchasing a new amplifier. A typical radiated test setup is shown in Figure 4.

Conclusion

The increased frequency range of this standard has brought to light some common test problems and their contribution to test error. Continuing efforts are needed to maintain a consistently repeatable test. Both harmonic distortion and amplifier linearity are issues that were not addressed by this standard in the past. All RF amplifiers can run in compression and can produce harmonics. If the amplifier is running in compression and if the antenna and cabling cannot be improved upon, a higher power amplifier will be needed. If harmonic content becomes an issue, RF filters will be needed to block out these harmonics. With some solid-state amplifiers, filters will not be needed. It is also a good idea to ask manufactures for examples of test data taken from production units. This data can aid in product selection and can provide a better level of confidence of manufacturers’ ability to meet their published specifications. Quality of testing and repeatability should be the goal of every EMC test lab. Repeatability is the important goal of these international test standards.

Source

IEC 61000-4-3 Ed3.0 2006 Electromagnetic compatibility (EMC) – Part 4-3: Testing and measurement techniques – Radiated, radio-frequency, electromagnetic field immunity test

Jason Smith is Sr. Sales Applications Engineer for AR Worldwide. His responsibilities include product applications support to customers, technical training, technical writing, and guidance for product development. He has over seven years’ EMC experience as a lab manager and test engineer for independent EMC test labs. He has experience testing to IEC, MIL-STD, DO160, Medical, Telecom, and Automotive requirements. Jason can be reached at 215-723-8181, jsmith@ar-worldwide.com.