Introduction

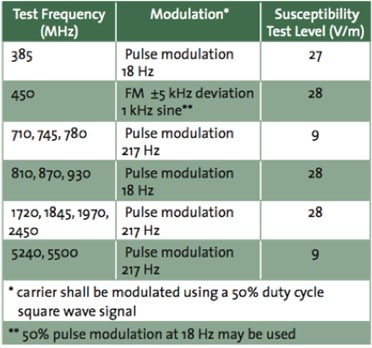

Companies making medical products have much more stringent requirements now that the new IEC 60601-1-2 (Edition 4) became effective June 17, 2017. One of the many changes included increased radiated immunity requirements in several specific wireless and communications bands (Table 1). Highlights of all the changes are included in Interference Technology’s free 2017 Medical EMC Guide, authored by Darryl Ray, and downloadable here.

The IEC also has a guidance document, TR 60601-4-2:2016 that provides help in assessing products for general immunity. The highlights and download links for this are also included in the 2017 Medical EMC Guide mentioned previously.

Troubleshooting radiated immunity can be extremely difficult unless you have the means to simulate the appropriate RF immunity levels in-house. Traveling back and forth to the EMC test lab can consume a lot of time and cost many thousands of dollars. I’ve written a number of articles on simple techniques to create the lower levels typically required for general consumer or commercial products, but achieving the higher levels as high as 28 V/m is beyond the capability of these simple methods (see References).

Case Study

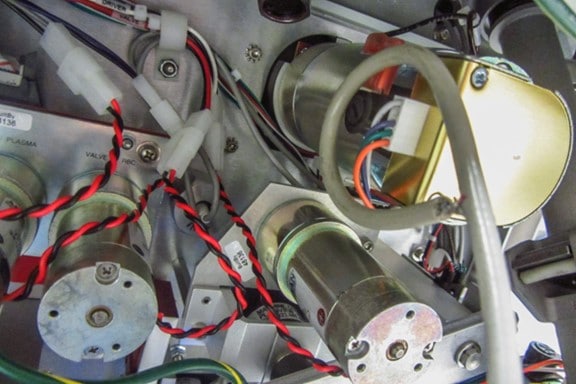

I was recently called in by a client to help with a tough RF immunity issue they’d been attempting to troubleshoot on a large medical product. It included several motors, a couple of circuit boards and several wiring harnesses – much of which was unshielded with a large plastic enclosure. They’d tried shielding cables and grounding several points to chassis – all of which helped to a degree. The good news was that they were passing radiated emissions OK, but there were still a couple of frequencies that were susceptible.

The issue during qualification testing was that two of the motors were “taking off” at a much higher than normal RPM. Each motor speed was controlled via a digital encoder feedback system and the suspicion was that RF was affecting this circuit – either directly or upstream somewhere.

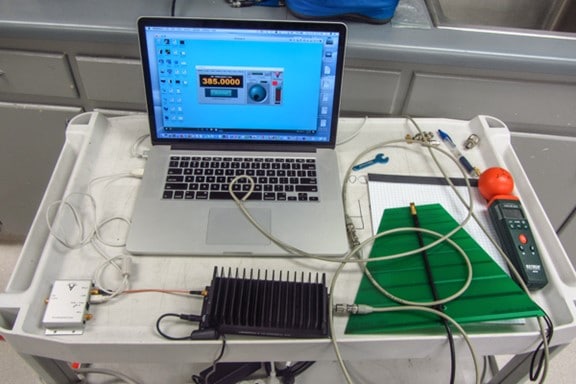

I decided to use a technique I’d used with a previous client by augmenting my simple immunity test system with a small 3-watt broadband amplifier, rated from 10 to 1000 MHz. Vectawave makes a compact amplifier, model VBM 2500-3 that was perfect for the job. I had used this previously to generate up to 40 V/m from the PC board log-periodic antenna (close in) that I normally use for emissions troubleshooting. The basic setup is shown in Figure 1.

The list of equipment used is comprised of the following:

- Windfreak SynthNV RF synthesizer (https://windfreaktech.com)

- Vectawave VBM 2500-3 RF amplifier (see Referances)

- 400 to 1000 MHz PC board antenna from Kent Electronics (http://www.wa5vjb.com)

- Homemade H-field probe made from coax cable

I also have an Extech 480836 E-field meter for measuring the resulting field levels, but this is really optional for this sort of troubleshooting. What we’re trying to do is cause a controlled disruption in the product under test and the absolute level is secondary in importance.

The Windfreak SynthNV RF synthesizer can tune from 34 to 4,400 MHz and create output levels to +19 dBm. It is USB-powered and controlled by a supplied Windows software (see Figure 2).

However, for this particular case, that wasn’t a sufficient level to duplicate the issue. So I connected the synthesizer to the 3-watt amplifier, which boosted the level from the antenna to 16 to 20 V/m, but that was still not enough to cause disruption. I found it difficult to get the antenna in close enough to the various cables and circuit boards.

I then tried a homemade H-field probe fashioned from a piece of coax cable. The loop was about 5 cm in diameter and the center conductor is simply soldered to the outside of the shield. Probing around the circuit boards and cables didn’t cause any issues, but when the loop was brought near the motor encoder circuits, the motors started spinning up to high speed. Success! See Figure 3.

Once we were finally able to duplicate the problem, the fix was simple and just involved the addition of a ferrite choke around the encoder cable. See Figure 4. As in many cases, the motor assembly was an OEM product, so could not be easily redesigned for better immunity margins, so the ferrite filter was the lowest cost solution.

Just a note… when selecting a ferrite choke, make sure the peak impedance is generally close to the affected frequencies for best results. Much more information on ferrite selection may be obtained from the excellent handbook from Würth Electroniks, Trilogy of Magnetics. This may be obtained from your local field engineer.

Conclusion

The new radiated immunity levels for medical products can be a real challenge as manufacturers are forced to re-qualify products to Edition 4 of the standard. Troubleshooting “blind” at the EMC test lab can be costly in time and expense. However, a simple troubleshooting solution costing about one day’s time at the test lab can help pinpoint sensitive areas of a product in a few minutes.

References

- 2017 Medical EMC Guide, Interference Technology, http://learn.interferencetechnology.com/2017-medical-emc-guide/

- TR 60601-4-2:2016, IEC, https://webstore.iec.ch/publication/24811

- Vectawave VBM 2500-3 amplifier, http://vectawave.com/products/general-purpose-amplifier-modules/

- Trilogy of Magnetics, Würth Electroniks, http://www.we-online.com.

- Wyatt, Inexpensive Radiated Immunity Pre-Compliance Testing, https://interferencetechnology.com/inexpensive-radiated-immunity-pre-compliance-testing/