Dion Neri, Chief Engineer

MCG Surge Protection, Inc.

Contrary to the popular perception that only a high-energy lightning strike can damage equipment, the truth of the matter proves otherwise. How does non-lightning damage occur? Every day surges enter a facility via the AC power lines as a result of grid switching and other sources. These surges will not typically cause breakers to trip or fuses to operate because they are too fast and do not have sufficient energy. But their energy does exceed the maximum electrical ratings of semiconductor components used in equipment. Over time both the electrical spacings between conductors and the conductors themselves become compromised. When the dielectric or insulator between the conductors breaks down and loses its insulating properties, the spacings are compromised because what was once a virtual open circuit is now a low resistance, unintended pathway. Failure of the spacing can also be due to arcing across the surface of the dielectric as opposed to through it. Either way, the presence of any voltage (nominal or surge) impressed on the compromised spacing can cause the conductors to bridge. Conductor damage occurs when they’ve pass surge currents of sufficient magnitude and duration, resulting in changes to their molecular structure. The result is they may no longer be able to carry nominal currents and their ability to pass surge currents is greatly diminished. When tiny conductors can no longer pass the surge current, they open like a fuse. In semiconductors, constantly exceeding the maximum ratings between electrodes will eventually cause a breakdown internal to the device and subsequent failure. Surge protection prevents damage by eliminating the overvoltage and overcurrent stress caused by surges, keeping the components within their safe operating voltage region. Today’s smaller and more densely packaged electronics are more susceptible to damage from surges than ever.

A common example of equipment highly susceptible to damage by surges is control boards in unprotected Automatic Transfer Switches (ATS). The ATS is one of the first components connected to the distribution transformer, consequently it receives the full brunt of the surge. Downstream equipment receives less of the energy due to dissipation and fanning out of the surge. (But it’s unwise to be lulled into a false sense of security regarding equipment deep in the system. See “Data Line Protection Considerations,” sidebar.) On one particular ATS application, a control board was working fine for about six months and then suddenly it ceased to function. The control assembly was visually inspected and no damage was observed. Closer electronic inspection and troubleshooting revealed that two integrated circuits had shorted out. Not only did the two components cease to operate, they dragged down the entire DC bus leaving the other surviving components without sufficient power to perform vital functions.

Such a scenario is a costly predicament because the assembly has to be replaced and, until such time, the switch will not operate. It is of note that this event occurred in a part of California where lightning activity is not that common. The cause of the failure was attributed to utility switching surges, which occur on a daily basis. A utility switching surge may be caused by actual utility company switching or the operation of and powering up/down of heavy machinery (e.g. foundries, presses, cranes, and conveyors) from your grid-connected neighbors. A new control board costs $4,000.00, excluding installation. Add downtime costs at the businesses serviced by the Automatic Transfer Switch and the real cost of surge damage emerges. And, unless surge protection is applied, odds are that the replacement board with fail just as the original board did. Unlike the occasional lightning occurrence in this geographical area, utility surges are repetitive and will show up on a regular basis. Less visual drama, but more insidious damage.

To put it into perspective, think about ESD (Electrostatic Discharge). ESD is a form a surge, albeit a lower energy one. However, many components are sensitive to ESD and can be damaged by virtue of improper handling alone. For example, someone carrying an integrated circuit picks up an ESD charge then hands the component to someone else. A tiny spark occurs which is caused by both subjects being at a different voltage potential – possibly even as much as a 15 to 30kV difference. The energy in this spark is sufficient to cause damage to integrated circuits and other sensitive semiconductor devices before the component is even put into the assembly and powered up. During a surge event, a powered component already carrying the load of its nominal voltages and currents is now required to handle superimposed surge voltages and currents that it was not designed to address. Thus, it does not take much energy to cause damage and render equipment nonoperational.

The ATS is the gateway of power to the facility and all power to critical loads flows through it. The ATS passes both utility (normal) power and generator (emergency) power and automatically switches from utility to generator power should the utility power go off. If the ATS goes down, the facility power feed will be disrupted. Given the cost to replace such an assembly as well as loss of revenue caused by the damaged switch, it’s imperative to protect this critical piece of hardware. See Figure 1.

Equipment failure is common but can be prevented by making a onetime, appropriate surge protection device (SPD) purchase. Use an AC protector on the ATS’s Normal input with a surge current rating of 160,000 Amps per phase minimum. Depending on service size and lightning frequency, a heftier unit may be required due to the higher surge energy it will experience. Smaller capacity protectors are required on the Emergency Panel and the Emergency feed to protect those areas as well. Doing so eliminates loss of revenue and ongoing replacement of damaged hardware. Easy to install, quality surge protection equipment is designed to outlast the very equipment it is protecting. It is not uncommon for a properly designed surge protective device to last greater than twenty years. Whether your equipment is subject to dramatic nearby lightning events or the insidious repetitive surges, employing appropriately-rated SPDs will ensure that your equipment realizes its design life and functions reliably for many productive years. “Appropriately-rated” means that the protector is designed to repeatedly handle the surges at a given location for decades. Avoid using poor quality or under-rated surge protectors as this will result in poor results and higher costs in the long run. Correctly choosing a protector is easily achieved by contacting a surge protection applications engineer.

Figure 1: Location of SPD (TVSS) for Automatic Transfer Switch and Critical Load protection

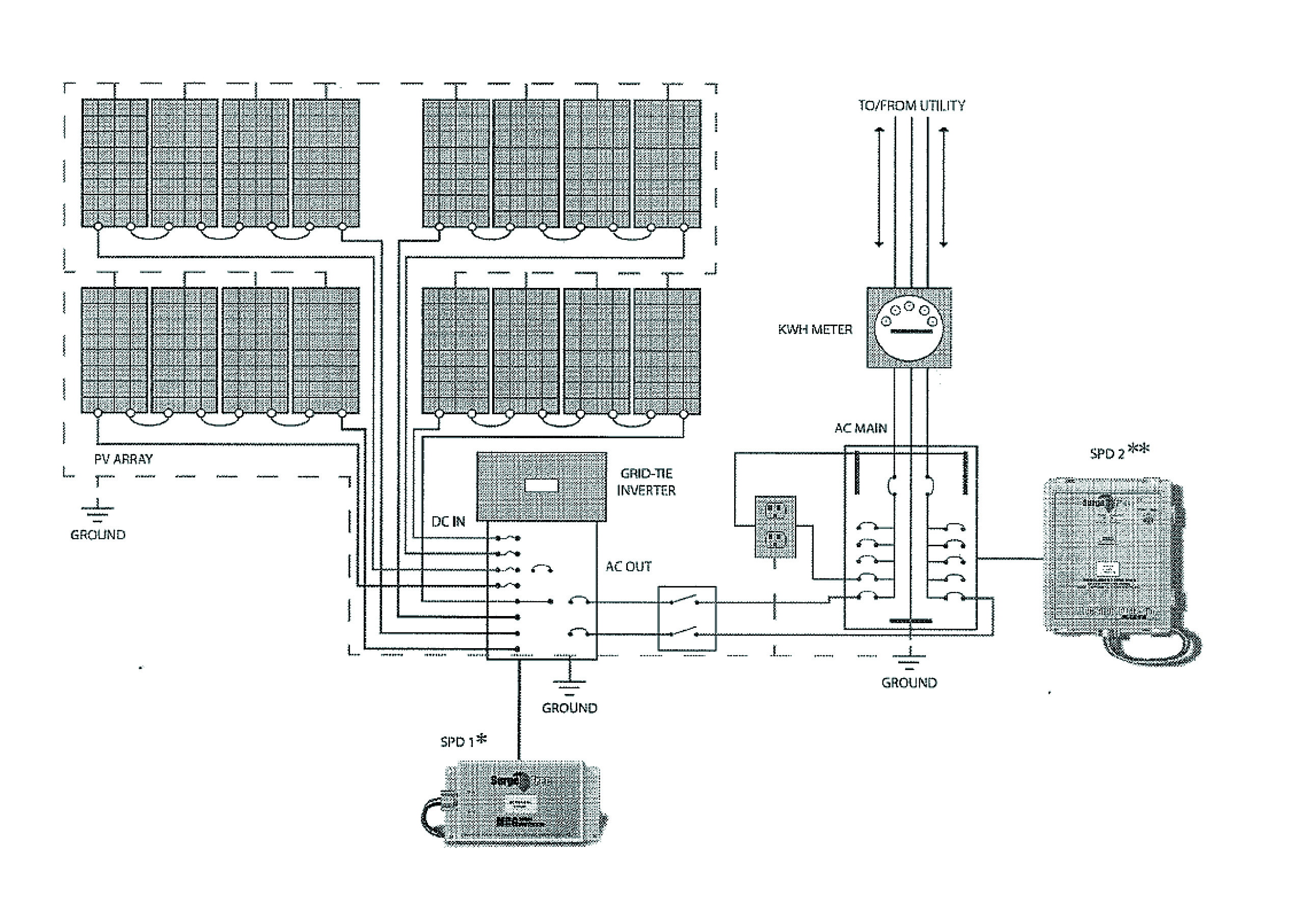

Like an ATS, an inverter is also the gateway of power, but for solar power or photovoltaic systems. Solar generated power flows into the inverter and is converted from DC voltage to AC voltage. To protect this device, a DC surge protector on the inverter’s input is required and an AC surge protector on its output, especially if it is a Grid Tie inverter since they are always exposed to surges from the utility grid. Figure 2 shows is an example of how to protect a Grid Tie inverter. Note that the AC protector’s function is two-fold as it also protects the AC loads wired to the panel.

*SPD 1 protects inverter’s DC Input

**SPD 2 protects inverter’s AC Output and Panel Loads

Figure 2: Protector locations for protection of inverter and AC panel loads.

Don’t Forget Data Line Protection

Figure 3 shows a typical example of damage caused by surges on data lines. A network switch is seemingly operating smoothly, until it’s not. The culprits are high-speed transients caused by differences in ground potential between the ports, represented by transistors Q1 and Q2. To address this problem, adding data line surge protection at the equipment at each end of the connecting cable protects the equipment at both locations. These protectors typically use RJ45 connectors, so installation is five minutes or less. Some installations may require protectors with screw terminals or IDC (insulation displacement connectors) like an IDC110 block, which are readily available. Installing data line protection prevents an entire network-connected department from sitting idle because it cannot connect to the Internet.

Figure 3: Ground potentional shift due to lightning current I1B

Dion Neri is Chief Engineer at MCG Surge Protection, Deer Park, NY. He can be reached at: 800-851-1508 or dion@mcgsurge.com