The essential information about which tests apply to automotive product types is now contained within the one directive.

Martin O’Hara, Trafficmaster, Cranfield, Beds, UK

INTRODUCTION

This article discusses the changes implemented in the new European Automotive EMC directive 2004/104/EC1. The new directive, released in November 2004, effectively replaces the existing Automotive EMC directive 95/54/EC beginning January 1, 2006.

BACKGROUND

The EU commission recognized shortcomings in the European Automotive EMC Directive 95/54/EC2 almost as soon, as it was released as it contained conflicts with other international standards—in particular, CISPR-253 for automotive component testing. It was considered by most automotive OEMs as inadequate as a basic standard for automotive products primarily due to lack of conducted transient testing in the directive. Another area of concern expressed by aftermarket equipment suppliers was the status of aftermarket products with “CE” approval to the generic EMC directive (89/336/EEC) and telecommunication products type approved to the R&TTE directive (1999/5/EC) that have no control function in the vehicle. The current status of these products in 95/54/EC is that after October 2002 these have to be “e”-marked for vehicle use.

In the late 1990s, the EU commission set-up a project to consider revisions to the Automotive EMC directive and York EMC Services (YES) won the contract to run the project. YES produced a detailed report on changes requested to the directive by the automotive industry; automotive OEMs, automotive tiered suppliers and EMC test service providers, as well as the wider consumer electronics and radio-communications industry. The “York Report”4 was well publicized within the EMC community and made freely available via the Internet. Many of the changes implemented in the new edition of the automotive EMC directive discussed here, reflect the findings of this work.

GENERAL NOTES ON THE NEW EU AUTOMOTIVE EMC DIRECTIVE

The new directive is still what is classified as an “old style” directive, this means that the tests and test levels are contained within the single directive document, however, it now references other international standards for some of the test methods and set-up. The referencing of multiple standards increases the cost for obtaining all necessary documentation, but being an “old style” directive still makes the cost and quantity of necessary documentation lower than with “new style” EMC directives. There is also less confusion over which tests apply to automotive product types as all the essential information is contained within the one directive.

The new directive (2004/104/EC) is a significant improvement over the current directive (95/54/EC), it is both clearer in the requirements and test levels. In using international automotive test standards it brings the test methods for the EU directive in-line with the test configurations used by most automotive OEMs. In the future translating the results from “e”-mark testing to an OEM specification will be much more straightforward.

Whereas the existing directive disguises the true limit lines applicable by using phrases such as “shall be at least 2 dB below the reference limit” in the text of the directive, the new edition removes any possibility of confusion and explicitly states precisely what the limits levels are. If the rewrite were purely for clarification purposes alone it would be worthwhile as 2004/104/EC is significantly easier to read than 95/54/EC. A prime example of the improvement in clarity is the well defined “immunity related functions” in the first annex of the new directive, this clearly defines what interfaces are required to be immunity tested, an area left open to some interpretation in the current edition.

WHOLE VEHICLE TESTING

Although primarily only relevant to the vehicle manufacturers (OEMs), ultimately it is on-vehicle testing that is the final approval requirement for OEM line-fit products; the largest market segment for any type of automotive product. Changes to vehicle tests will also have an impact on those products that are only ever tested on-vehicle, certain sensors for example.

RADIATED EMISSIONS TESTING

The most significant change in 2004/104/EC for whole vehicle radiated emissions testing is the removal of the exclusion for compression-ignition engines (i.e., diesel engined vehicles). In 95/54/EC only spark-ignition (petrol) engined vehicles are explicitly covered by the broadband radiated emissions testing. The electronics on-board most vehicle models are identical between petrol and diesel variants; with the notable exception of the engine management controller. Most OEMs will have tested their diesel variants as well as their petrol versions, however, there is the option to not test diesel vehicles in the existing directive that is removed in its replacement.

The frequency range of 30 MHz–1 GHz, limit levels and test methods remain the same as the existing 95/54/EC directive for both 3-m and 10-m vehicle-to-antenna test set-ups, with the narrowband limits 10 dB below the broadband limits (Figure 1). The new directive utilizes CISPR-125 for its test set-up parameters that are otherwise not defined in the document, in particular the operating mode of the vehicle is taken from CISPR-12 directly rather than quoted in the directive.

Narrowband emissions has an “initial step” in 95/54/EC that permits omission of further testing if over the range 88 MHz to 108 MHz at the vehicle broadcast antenna the emission level measured is below 20 dBµV. This “initial step” option has been removed and full frequency range emissions testing for a whole vehicle is required in 2004/104/EC.

RADIATED IMMUNITY TESTING

A major change for immunity testing is an increase in the upper frequency limit from 1 GHz to 2 GHz. The field strength remains at 30 V/m over 90% of the 20-MHz to 2-GHz frequency band with a minimum of 25 V/m at any specific frequency point. Vehicle radiated immunity testing in the new directive refers to the standard ISO 114516 for free field test set-up, currently the test method is explicitly described in 95/54/EC. Although the 95/54/EC test method is similar to ISO 11451-2 for free-field testing, the ISO standard also allows Transmission Line System (TLS) testing of whole vehicles and consequently the new EU directive could also be interpreted to allow TLS testing for whole vehicles (Figure 2).

Another addition to the new directive is the use of BCI on-vehicle in accordance with ISO 11451-4, for the complete 20-MHz – 2-GHz frequency range where the vehicle size exceeds 12 m long and/or 2.6 m wide. This is potentially a significant cost saving but availability of BCI probes up to 2 GHz may in practice limit the up take of this test option.

The vehicle test conditions and fail criteria are explicitly tabulated in 2004/104/EC making the test engineers job easier and the directive more readable.

The test signal modulation in 95/54/EC is amplitude modulated (AM) only at 80% depth with a 1-kHz modulation frequency. This is retained in the 2004/104/EC for 20 MHz to 800 Mz. Above 800 MHz pulse modulation (PM) is used with a pulse width of 577 µs and a period of 4.6 ms. This PM scheme suitably represents the coding commonly used by mobile telephony and is a long overdue addition to this EU directive.

Only vertical polarization is specified for whole vehicle radiated immunity testing in 2004/104/EC, this is consistent with TLS testing but a departure from the existing EU automotive EMC directive test requirement.

INSTALLATION OF RADIO EQUIPMENT ON VEHICLES

The vehicle manufacturer is required to make a statement on the requirements for installation of RF transmitters in their vehicles as part of their application for approval certification to 2004/104/EC. This can potentially have an impact on restricting the equipment type and installation location of aftermarket radio equipment. As this is a statement on their approval documentation it is not necessarily obvious to either user or aftermarket suppliers (although it is likely to be repeated in the owners handbook) and could be a potential bone-of-contention should a problem come to light in service. For example the manufacturer may state use of mobile telephony with installed car-kits with an external antenna only, this would mean that anyone using a mobile phone without an installed kit whilst sat in the vehicle would be invalidating the vehicles certification? Should an unexpected event occur (e.g., airbag deployment) during such a situation the manufacturer could claim this is a specific exclusion and that due diligence has been demonstrated? It is possible that this may come into conflict with local product safety regulations and may ultimately not provide an adequate defense.

COMPONENT TESTING

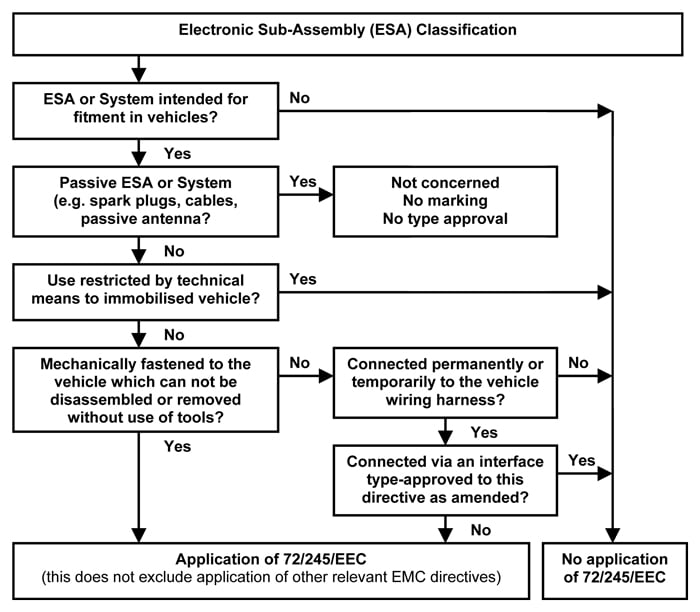

This is the area that OEM suppliers’ products and aftermarket automotive systems have to comply with to be sold as suitable for vehicle fit within Europe. Components and sub-systems are still referred to under the generic description Electronic Sub-Assembly (ESA).

An area where suppliers in certain EU markets should gain more access is the restriction to interpretation of the directive. For example the German market currently interprets 95/54/EC to prevent any aftermarket electrical product fit (with or without e-marking) without the vehicle manufacturers written confirmation that the product does not invalidate the vehicle type approval. This is effectively a restriction of trade for non-OEM approved products. The new directive does not allow manufacturers to restrict aftermarket products, with the exception of a general statement for radio equipment.

CE- AND R&TTE-APPROVED PRODUCTS

Products that are not permanently wired to the vehicle harness and can be removed without specialist tools, or are technically restricted to operation while the vehicle is stationary, will no longer have to prove compliance to the Automotive EMC directive once 2004/104/EC comes into effect. Such products can be CE marked (if necessary) and obtain a Declaration of Conformity via the generic EMC directive (89/336/EEC) processes, this includes self-certification and technical construction file (TCF) routes to compliance. The same situation is applicable for R&TTE products (e.g., mobile telephony and radio equipment) where meeting the R&TTE directive is determined as adequate for vehicle fit given the above provisos.

This change to the automotive EMC directive provides a method for some suppliers to reduce their testing by self certifying products (CE marking) based on “use of known good circuits” and TCF. However, there may be a commercial imperative to retain “e”-marking on some products to maintain credibility in the automotive marketplace. There could also still be the dictated requirement from aftermarket product retailers, forcing “e”-mark testing on the product by otherwise threatening to remove from their sales portfolio. It is highly unlikely that automotive OEMs will approve products for fit to their vehicles (e.g., at franchised dealerships), even as aftermarket items, if “e”-mark certification is not obtained as a minimum.

RADIATED EMISSIONS TESTING

There are no changes to the test frequency range or limit levels applied (broadband and narrowband, Figure 3). There is a significant and sensible change to the test set-up, this now references the standard CISPR-25, the most commonly used automotive OEM reference set-up for both radiated and conducted emissions. Consequently it should be possible to utilize measurements taken for “e”-mark certification to compare directly with OEM specification requirements specified under CISPR-25 test conditions.

The main difference in test set-up is a change in test table height from 1 m to 0.9 m and the associated change in height of the receiving antenna. Overall the effect of this small table height change will have minimal impact on the radiated emissions measured and results from the current 95/54/EC test set-up and 2004/104/EC (CISPR-25) are very similar.

CONDUCTED EMISSIONS TESTING

The specifications section (Section 6) in the directive update states that “ESA(s) shall be tested for radiated and conducted emissions … ” (section 6.1.1.2). CISPR-25 is the radiated emissions reference specification for most automotive products, this is the de-facto standard for OEM conducted emissions testing, however, the new EU directive utilizes the transient immunity specification ISO 7637-27 as its conducted emissions reference standard.

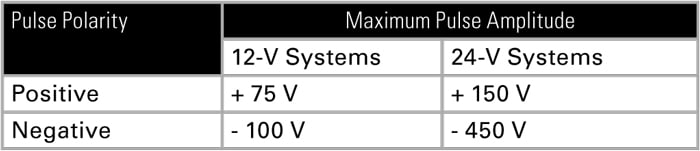

The use of ISO 7637-2 for conducted emissions testing is unusual (although the test methods have always been in the ISO 7637 standard) and the definition of pass/fail limits is not as well defined as the limits in CISPR-25. Measurements of the voltage transients only (previous editions of ISO 7637 included transient current measurements) are made with an oscilloscope and there are no frequency parameters defined, only test time capture for nanosecond (ns) and microsecond (µs) pulses or milli-second (ms) pulses. Emission failure levels are also defined in absolute voltage terms rather than the usual decibel-microvolt (dBµV) measure (Table 1).

Although this is a new test requirement, the limits and measurement methods are such that the additional test cost will be relatively low (these tests can be performed at the same time as conducted immunity, see below) and the probability of failure is extremely small for all except inductive coil drivers and motor control circuits. Even inductive load drivers should be able to meet these requirements with the minimum of suppression circuitry on their drive outputs.

There are exemptions from conducted emissions testing stated in Section 8; “Exceptions”, where Section 8.5 states; “ESAs that are not switched, contain no switches or do not include inductive loads need not be tested for conducted emissions … .” This suggests that just about all electrical products will have to be tested for conducted transients, even a digital clock in a modern car has switches for adjusting the time settings. This may be a pedantic interpretation of the wording and the term “switches” may specifically refer to electrically switching products, however, this is still a broad definition and anything with a digital oscillator (including those operating below the usual 9-kHz cut-off frequency) would still be encompassed by this definition.

RADIATED IMMUNITY TESTING

As with whole vehicle testing the most significant change has been to extend the upper frequency range to 2 GHz for radiated immunity testing plus the adoption of the relevant ISO standards (ISO 114528, parts 1 to 5) for test set-up. The same AM and PM scheme introduced for whole vehicles is repeated for components; 80% AM for 20 MHz to 800 MHz, 577 µs/4.6 ms PM for 800 MHz to 2 GHz.

Free field testing is specified for vertical polarization only in 2004/104/EC, this should offset the increased test time for the frequency extension by having a single polarization mode, hence immunity test cost should be unaffected by the update.

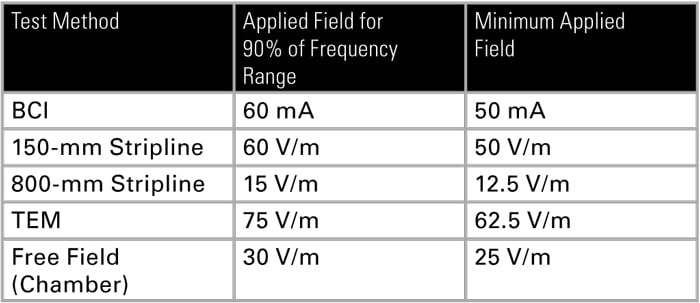

There has always been a discrepancy with the EU automotive EMC directive and OEM standards in the area of radiated immunity testing. The magnitude of the applied field for each of the applicable test methods is different (Table 2), this is unusual for an EMC standard, but is consistent with the existing edition of the Automotive EMC directive. The different levels were based on comparative testing of the different test methods for equivalent effects, however, access to this information seems to have been lost in the committee stages or may never have been made public. Most OEM standards use the same field strength for whichever test method they apply and usually an equivalent BCI current level to the equivalent field strength (i.e., 100 V/m for free-field or TLS measurement methods and/or 100 mA for BCI). Consequently this has always given the 30-V/m free field test in the EU directive the image of a less aggressive immunity test, hence easier to meet, and will continue to do so.

CONDUCTED IMMUNITY TESTING

The new Automotive EMC directive requirement should more accurately be called transient immunity testing. This is the most significant single change to the new directive and constitutes new test regimes not previously implemented in the 95/54/EC directive. The new directive utilizes ISO 7637-2: 2002. The ISO 7637 series of standards are commonly used by OEMs and are a basic test of any ESA for electrical compatibility with the vehicle environment. Consequently, although previously not compulsory, these tests should be performed on any electrical products intended for vehicle fit.

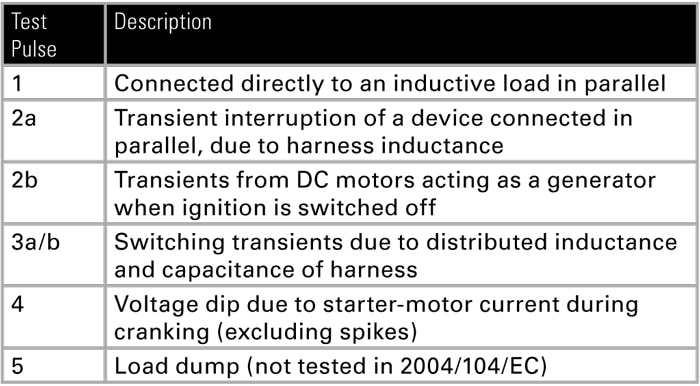

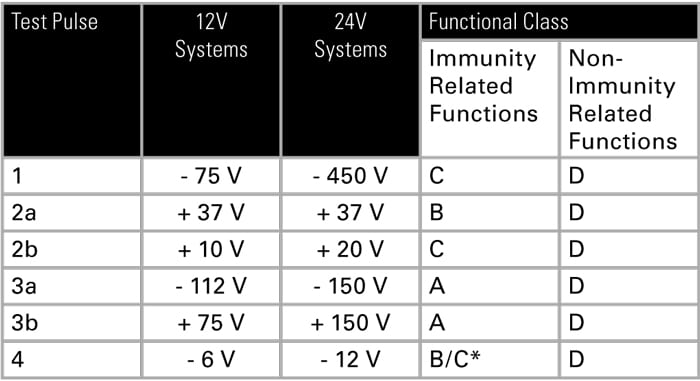

Tests are performed on lines connected to the power supply only, including lines operationally connected such as ignition sense and switched ignition-supplied lines. The tests include pulses 1 to 4 of ISO 7637-2, including switching of inductive loads and cranking, but noticeably excludes the load dump pulse (pulse 5, see Table 3 for pulse definitions). Severity level 3 is utilized for all tests for both 12-V and 24-V systems (values given in Table 4). Level 3 is quite a severe test level, especially for aftermarket products, however, on-vehicle measurements made and published by 3C Test Ltd9 have shown that this test level is typical of the transient voltage magnitudes and waveforms observed at the accessory socket in a modern vehicle.

The applicable functional class (see appendix A for definitions) is very low for non-immunity related functions, however, this may be applicable to only a few products given the newer definitions of what constitutes an immunity related function in the update. The functional class for immunity related function is tough, especially for test pulse 3 where the ESA should technically remain within parametric tolerances. In reality it is difficult to accurately test that functional class A is obtained since this would require ATE to be running while the ESA is undergoing transient immunity testing, a condition rarely (if ever) encountered. Providing the ESA does not perform any unexpected function during exposure, functional class A and B are difficult to distinguish.

THE IMPACT ON EXISTING PRODUCTS

Until the 2004/104/EC becomes law existing automotive products will still have to comply with the requirements of 95/54/EC. Products that are already on the market when the new directive becomes law will not have to be retested immediately, unless there is a significant design change to the product; the determination of “significant” is at the discretion of the relevant certification agency and guidance on this is not yet available.

LINE-FIT PRODUCTS

Line fit products, supplied directly to the OEM, are unlikely to require any design changes to meet the requirements of 2004/104/EC. Most automotive OEMs have an EMC specification that is significantly more stringent than the EU directive; existing or new version.

The possible exception to the above is in the area of immunity testing, where currently the definition is mainly related to the vehicle control surfaces (i.e., direct vehicle control implications) and safety features. The new directive now also includes “driver distractions” including optical and acoustic distractions. Although the directive clarifies some of the immunity related functions in the text, the rather broad “driver disturbance” classification could be applied to in-car entertainment (ICE) and line-fit telematics systems such as satellite navigation. In the existing directive interpretation these later products are exempt from immunity testing (radiated immunity only in 95/54/EC). Telematics and ICE products often have a lower severity level in many OEM specifications. Consequently there could be cost associated with re-design of some in-vehicle products to meet the increased immunity requirement of the new directive.

AFTERMARKET PRODUCTS

Many, if not most, aftermarket products are unlikely to be able to meet the full requirements of 2004/104/EC. In particular the relatively aggressive conducted transient immunity requirements and the radiated immunity test requirements will not be currently tested on many aftermarket products if they have no line-fit derivative. Few suppliers go to the expense of performing non-essential additional tests on their products.

The cost of re-designing certain aftermarket products to meet the increased immunity requirements may be prohibitive for relatively simple devices, in particular aftermarket ICE and devices such as hands-free phone kits. However, these could be CE marked and then be used in-vehicle. The intervention of a Technical Service is required to determine that the product is non-safety related (hence has no immunity requirements to the Automotive EMC directive) prior to following this route to compliance, otherwise the product could be banned from sale for use in-vehicle. The product will still have to meet the essential emissions requirements of the Automotive EMC directive to obtain its declaration of conformity and this also has to be assessed by a Technical Service, hence some form of testing is still likely to be required.

Consequently, e-marking will not be required for non-immunity related aftermarket accessories (Figure 4); however, they will need to do both:

- Self-certify compliance to the Automotive Directive emissions and conducted transients requirements, and

- Obtain a certificate from the automotive authorities to certify the product or range of products is not related to immunity and thus does not need type approval.

COMMERCIAL VEHICLES AND COMPONENTS

The basic requirement is that (like 95/54/EC) it will be mandatory under whole vehicle type approval (WVTA) for passenger cars (M1 category) and their aftermarket accessories, and at Member State discretion whether to apply it to other categories of vehicle. Therefore, for goods vehicles and buses, and for components intended for fitment to these, each member state has discretion as to whether or not to amend national legislation to require that new approvals and new registrations have to be approved to 2004/104/EC for EMC.10

TIMESCALES

The new Automotive EMC Directive 2004/104/EC was published in the Official Journal (OJ) of the EC in November 2004 and is available on-line at www.autoemc.net.

- New approvals to 2004/104/EC are available from 1st January 2006.

- New vehicle or component type approvals for EMC must comply with 2004/104/EC from 1st July 2006, testing to 95/54/EC will no longer possible from this date.

- Existing vehicles and components already approved for EMC before 1st July 2006 can carry on being sold.

- New registrations of passenger cars and all new aftermarket components on sale that are intended for fitment to passenger cars must comply from 1st January 2009.

CONCLUSION

There are possibly some missed opportunities in the radiated emissions and immunity tests. Why, for example, has the frequency limit for radiated emissions not been extended to 2 GHz to match the immunity range and cover mobile telephony interference risks? There is also an industry push for higher frequency wireless communications in the cabin, particularly Bluetooth (2.45 GHz) and similar technologies for hands-free phone interfacing. An extension of the radiated emissions and immunity requirement to 3 GHz would have covered most foreseeable in-vehicle technologies and reduce the need for yet another update in 3 or 4 years time.

Undoubtedly the new automotive EMC directive is a well-written document, clarifying many aspects of the test process and referencing international automotive test standards for the test methodology. Increasing the radiated immunity upper frequency range and use of PM coding is a somewhat overdue extension to cover mobile telephony products. Similarly the inclusion of transient immunity is a sensible test regime for any automotive electrical product.

My greatest concern is the possible use of self-certified CE marked products in-vehicle. However, the requirement for an automotive Technical Service assessment should prevent the excess of non-compliant CE marked products12 making their way into the vehicle-fit market.

ACKNOWLEDGMENTS

I’d like to thank Mike Lowe of the UK Department for Transport and Terry Beadman of MIRA Ltd for their assistance in preparing this article.

REFERENCES

- COMMISSION DIRECTIVE 2004/104/EC of 14 October 2004 adapting to technical progress Council Directive 72/245/EEC relating to the radio interference (electromagnetic compatibility) of vehicles and amending Directive 70/156/EEC on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers.

- COMMISSION DIRECTIVE 95/54/EC of 31 October 1995 adapting to technical progress Council Directive 72/245/EEC on the approximation of the laws of the Member States relating to the suppression of radio interference produced by spark-ignition engines fitted to motor vehicles and amending Directive 70/156/EEC on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers.

- CISPR 25 “Limits and methods of measurement of radio disturbance characteristics for the protection of receivers used on board vehicles” (2nd Edition 2002).

- Study on the Application of Directive 95/54/EC Relative to the EMC of Road Vehicles, I.E. Noble, I.D. Flintoft, L.M. McCormack, 24th April 2001 (http://www.yorkemc.co.uk/research/automotive).

- CISPR 12 “Vehicles, motorboats and spark-ignited engine driven devices Radio disturbance characteristics – Limits and methods of measurement” (5th Edition 2001).

- ISO 11451 “Road vehicles – Electrical disturbances by narrowband radiated electromagnetic energy – Vehicle test methods.”

Part 1: General and definitions (2nd Edition 2001).

Part 2: Off vehicle radiation source (2nd Edition 2001).

Part 4: Bulk current injection (BCI) (ISO11451-4: 1st Edition 1995). - ISO 7637- 1 “Road vehicles – Electrical disturbance from conduction and coupling

Part 1: Definitions and general considerations” (2nd Edition 2002).

Part 2: Electrical transient conduction along supply lines only on vehicles with nominal 12 V or 24 V supply voltage” (2nd Edition 2004). - ISO 11452 “Road vehicles – Electrical disturbances by narrowband radiated electromagnetic energy – Component test methods.”

Part 1: General and definitions (2nd Edition 2001).

Part 2: Absorber lined shielded enclosure (2nd Edition 2001).

Part 3: Transverse electromagnetic mode (TEM) cell (2nd Edition 2001).

Part 4: Bulk current injection (BCI) (2nd Edition 2001).

Part 5: Strip line (2nd Edition 2002). - Transient Test Requirements for “e”-Marking – Necessity Or Bureaucracy?, James Gordon-Colebrooke and Alex McKay, p 108 – 119, Automotive EMC 2003, 6th November 2003.

- Release of 2004/104/EC (the replacement Automotive EMC directive), Automotive EMC Newsletter, Issue 8, December 2004.

- The Effects of the New Automotive EMC Directive, Terry Beadman, p 6 – 12, Automotive EMC 2004, 12th October 2004.

- Compliance Update Seminar, Automotive EMC Newsletter, Issue 7, September 2004.

Appendix A: ISO Failure Mode Severity Classification

All classifications given below are for the total device/system functional status.

Note: The word “function” as used here concerns only the function performed by the electronic system.

Class A: all functions of a device or system perform as designed during and after exposure to interference.

Class B: all functions of a device/system perform as designed during exposure; however, one or more of them may go beyond the specified tolerance. All functions return automatically to within normal limits after exposure is removed. Memory functions shall remain Class A.

Class C: one or more functions of a device or system do not perform as designed during exposure but return automatically to normal operation after exposure is removed.

Class D: one or more functions of a device or system do not perform as designed during exposure and do not return to normal operation until exposure is removed and the device or system is reset by a simple ‘operator/use’ action.

Class E: one or more functions of a device or system do not perform as designed during and after exposure and cannot be returned to proper operation without repairing or replacing the device or system.

Martin O’Hara is a senior design consultant for Trafficmaster. He can be reached via e-mail at [email protected]. Find more information about the Auto EMC group at www.1klic.com/762.