This article is the second and final part of Static Control Resilient Flooring Qualification Procedures Ensure Space and Defense ESD Compliance. Read Part 1 here.

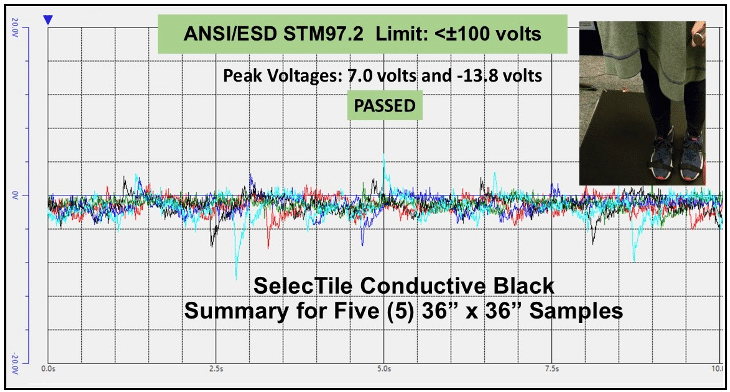

ANSI/ESD STM97.2

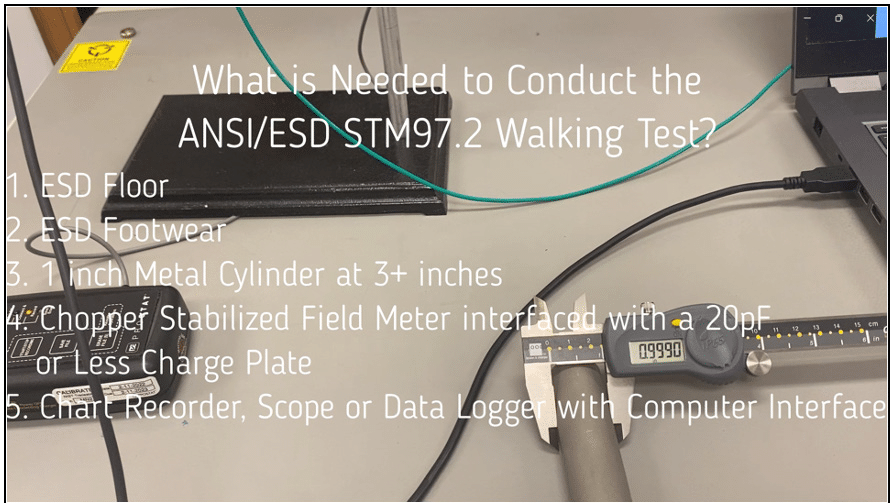

This critical standard test method attests to the static control resilient flooring’s ability to minimize charge buildup and provides the user with traceable data to assign a voltage flooring rating within the EPA.

Static Generation or Voltage in Combination with a Person (Figure 10) testing requires a result at <±300 volts for static control carpet when tested per AATCC-134 (Electrostatic Propensity of Carpets) wearing conductive footwear.

However, this test method is superseded by use of ANSI/ESD STM97.2 that sets a requirement of <±100 volts. ANSI/ESD STM97.2 applies for all types of flooring and is not limited to carpets.

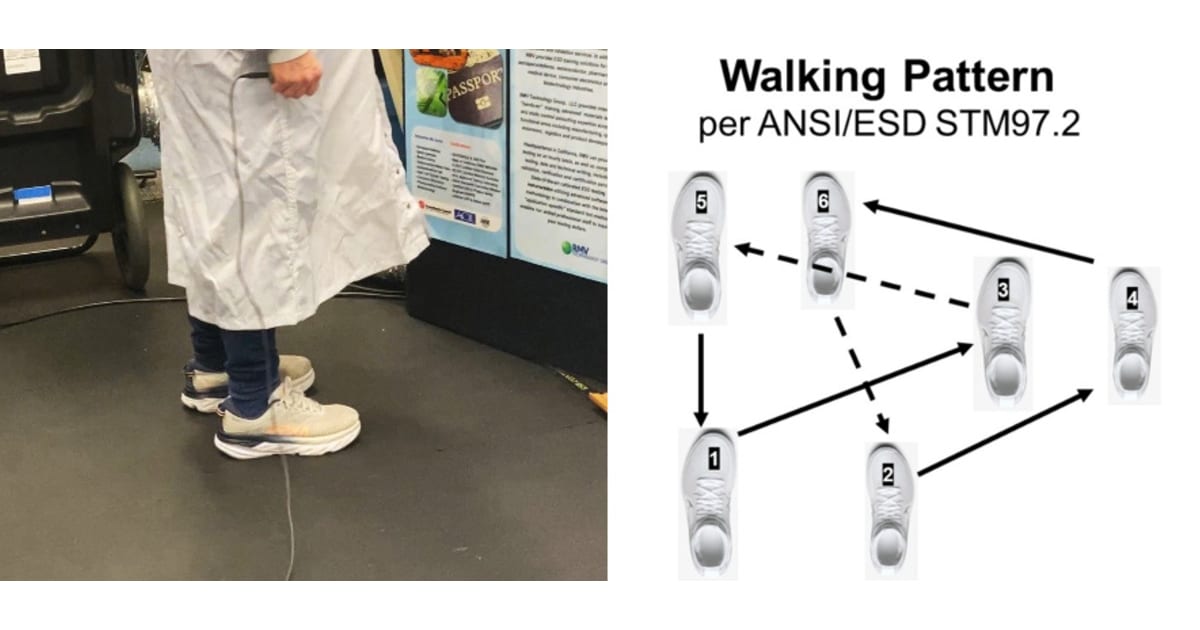

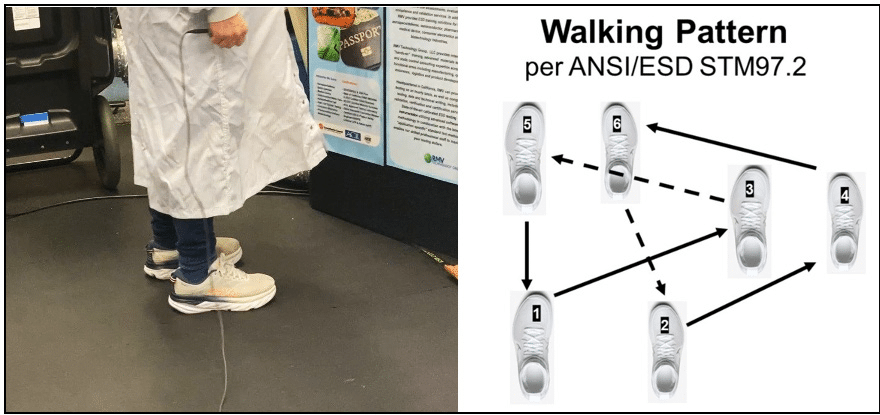

The following walking pattern is required per ANSI/ESD STM97.2 when conducting ESD qualification and installing testing as illustrated in Figure 10, right side.

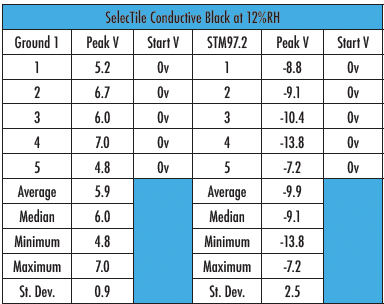

The voltage in combination with a person, flooring, and footwear per ANSI/ESD STM97.2 produced no voltage in excess of -13.8 volts for a PASS at <±100 volts. This floor product PASSED the test and was very low charging.

ANSI/ESD STM97.2 WALKING TEST IN PERSPECTIVE

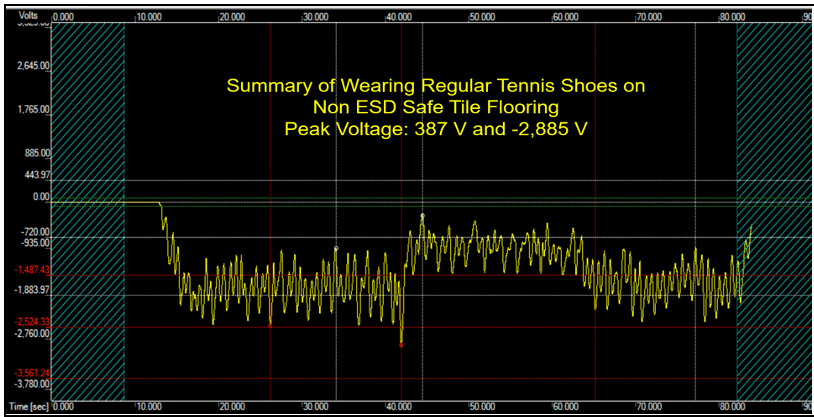

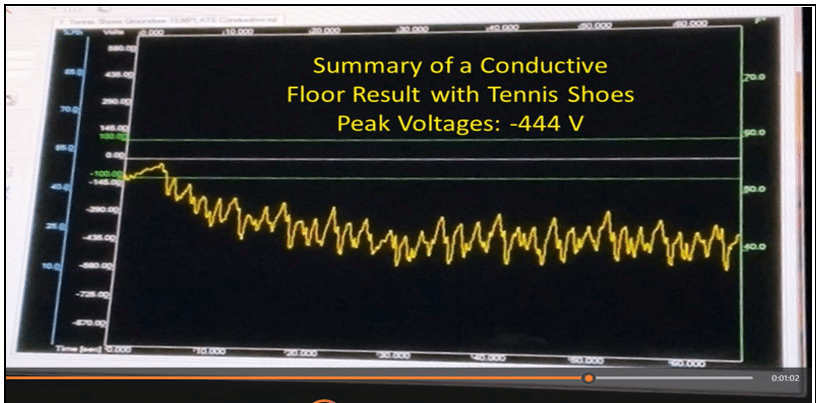

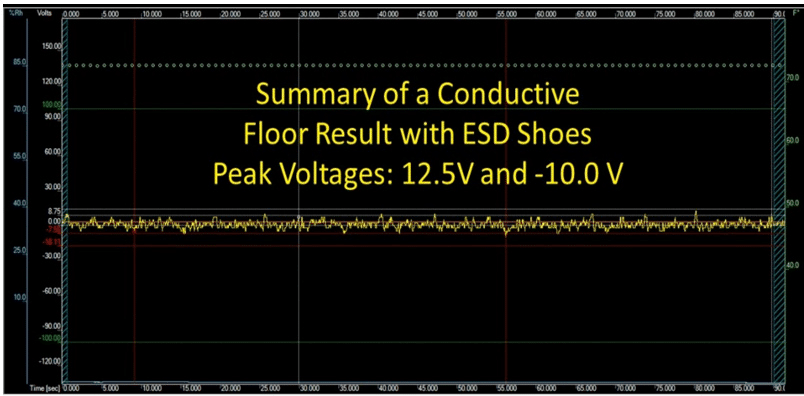

This discussion compares the results of floor performance for charge build-up while a person traverses various type of floors wearing regular tennis shoes or static control footwear in combination with both non ESD vinyl tile and SelecTile Conductive Black.

The reader can see that regular tile at 53.5%RH wearing tennis shoes (Figure 12) generates a peak voltage of 387 volts and -2885 volts in combination with a person. The peak voltage represents a risk to personnel in an explosive environment and ESD protected area (EPA) moving ESD sensitive devices (ESDS) in unshielded packaging.

When the evaluator wears tennis shoes and walks over the FreeStyle Conductive Black Tile (Figure 13), a peak voltage of -444 volts was recorded at 12%RH. This may not be suitable for an EPA in proximity to ESDS devices but low enough to minimize the risk of sparking in an explosive environment.

Lastly, at 12%RH, the evaluator wears ESD safe footwear traversing across FreeStyle Conductive Black Tile floor produced a very low peak voltage at 12.5 volts and -10.0 volts. The peak voltage is well below the ANSI/ESD S20.20, Table 2; NASA-STD-8739.6B, Section 7 and the DOD 09 6X XX designation.

5. ELECTROSTATIC DECAY

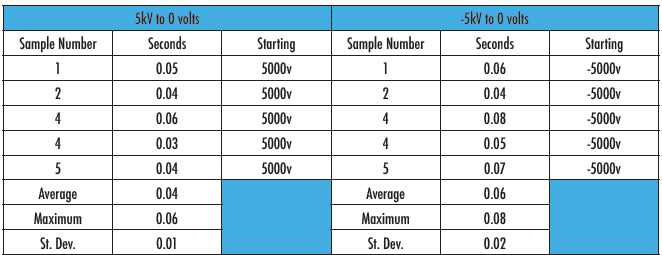

Current federal 09 6X XX requirements incorrectly call out Fed-STD-101C/4046.1. Today, this test method has been revised to Mil-STD-3010C, Method 4046 and is conducted in a controlled environment.

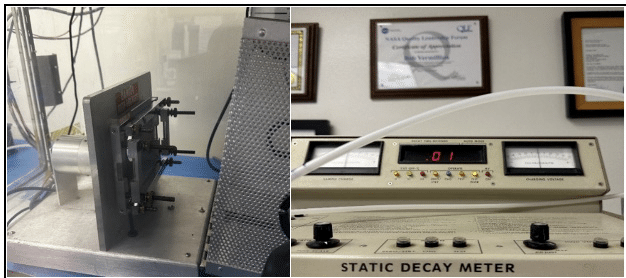

The test is conducted using precut floor samples measuring 3-1/2” x 5-1/2” and clamped into the fixturing of an electrostatic decay testing system (Figure 15, left side). The specimens are charged to ±5000 volts and grounded to facilitate static decay to 0 volts for a limit of <0.25 seconds.

This test demonstrates the flooring’s ability to bleed off charge and is appropriate for US Government qualification and installation certification to a 09 6X XX designation.

In short, due to the significant investment required for static control flooring, dependence upon a supplier’s technical data sheet alone can prove costly!

The FreeStyle Conductive Black Tile static resilient flooring performance met all the requirements for qualification to the following test methods:

- ANSI/ESD STM7.1 for Resistance to a Groundable Point & Point to Point Resistance

- ANSI/ESD STM97.1 for Resistance in Combination with a Static Control Floor and ESD Footwear

- ANSI/ESD STM97.2 for Voltage in Combination with a Person and Flooring wearing ESD Footwear

- MIL-STD-3010C, Method 4046 for Electrostatic Decay of the Floor Material

Acknowledgement:

A Special Thank you to Mr. Thomas Ricciardelli, CEO & Owner of SelecTech, Inc., Flooring Products for providing the samples for testing that made this article possible. Tom can be reached at 508.583.3200 or tricca@selectech.com