Bob DeLisi

Principle Engineer – EMC

Underwriters laboratories Inc.

Michael Windler

Operations Manager NA EMC

Underwriters laboratories Inc.

Introduction

Electromagnetic compatibility (EMC) testing and certification has become an integral part of product regulatory compliance. With the growing number of wireless communications devices being introduced into the RF environment, the test site that products are measured on have to ensure that emissions from the test artifact is not compromised by these external interferers. In today’s EMC testing environment there are two typical types of radiated emissions test sites; open area test sites (OATS) and semi-anechoic chambers. Whether you are considering building a test site or enlisting the assistance of an independent laboratory, there are a few key issues to consider when comparing open area test sites to semi-anechoic chambers. Our experience in operating both OATS and semi-anechoic chambers has uniquely qualified us to present an objective viewpoint. This article explores some of the pros and cons of using both technologies, such as construction and maintenance costs, test repeatability, measurement accuracy and site productivity.

Open Area Test Sites

The traditional, and current reference, test site for conducting radiated emissions measurements is an open area test site. Due to the abundance of such sites, a majority of radiated emissions compliance testing is still performed at these sites. The rising popularity of cellular phones, wireless PDAs, Blackberrys, HDTV signals, satellite transmissions and overall expanded use of additional radio frequency bands, continue to make it increasingly difficult to conduct emissions tests using OATS because of the increased presence of these ambient emissions.

An ideal open area test site is defined as a perfectly flat, infinitely large, continuous ground plane having infinite conductivity and located in free space. The term “free space” is defined as an open area, free of objects which can reflect electromagnetic waves including buildings, electric lines, fences, trees, hills etc. Obviously, there are no sites in the world that are “ideal” since most OATS will have some degree of imperfection, although most test sites strive to be as near to ideal as possible.

The original OATS construction was an uncovered ground plane. As laboratories strived to test in all weather environments OATS were either retrofitted or constructed with partial and/or full coverings. These coverings allow laboratories to test in weather that in an unprotected environment would not be feasible. Recommended construction practices for standard and weather protected OATS are provided in the American National Standards Institute (ANSI), American National Standard Guide for Construction of Open-Area Test Site for Performing Radiated Emission Measurements, ANSI C63.7-1992. A standard OATS with a turntable has an obstruction free area formed by an ellipse as shown in Figure 1.

Weather protected OATS are defined in ANSI C63.7-1992 as:

a. Type 1 – Having a structure that encloses the equipment under test (EUT), the receiving antenna and the space between.

b. Type 2 – Having a structure that encloses only the EUT.

c. Type 3 – Having a structure that encloses instrumentation or test personnel outside the obstruction free ellipse.

With the issuance of ANSI C63.4:2000, the covered OATS was redefined as an alternative test site if the covering can become reflective with weather. The significance of this will be discussed under the qualifications of test sites.

Semi-Anechoic Chambers

With the ever growing use of the RF spectrum, indoor semi-anechoic chambers are making an attractive alternative environment for EMC testing. Because EMC semi-anechoic chambers begin as metal shielded enclosures offering 100 dB of attenuation, they effectively “block out” all RF ambient emissions from the surrounding area. These shielded enclosures are then lined with radio frequency absorbing materials, thereby simulating a free space environment above the ground plane through the absorption of RF signals not directly coupled to the receiving antenna.

Qualifying Test Sites

All sites used for radiated emission compliance measurements, be it an OATS or a semi-anechoic chamber, must be constructed to eliminate, significantly reduce or reliably control reflected energy from having an adverse affect on measurements. The most common measure of the performance of a test site is Normalized Site Attenuation (NSA) test. The NSA test is specified in the ANSI American National Standard for Methods of Measurement of Radio-Noise Emissions from Low-Voltage Electrical and Electronic Equipment in the Range of 9kHz to 40 GHz (ANSI C63.4–2003). While ANSI C63.4-2003 currently allows an OATS to be evaluated for NSA using several discrete frequencies and a single measurement location when performed with dipole antennas, a semi-anechoic chamber is required to be evaluated using swept frequencies and five distinct locations that define volumetric area, intended to be occupied by the EUT. It should be noted that if an OATS NSA is performed with broadband antennas then the use of discrete frequency qualifications is not acceptable and swept measurements are required. When a test volume is evaluated, the distribution of the NSA values for the five locations is a factor in test repeatability. In addition, the use of swept frequencies as opposed to distinct or “spot” frequencies provides a broader and more uniform view of the site performance. Should the OATS have covering, whether fully protected or partially protected, if the covering can affect measurements due to buildup of minerals as an effect of weather, then these sites are required to meet the same volumetric NSA requirements as a semi-anechoic chamber.

A NSA test is a measure of the transmission characteristics of a test site between the point where the equipment under test is located and the receiving antenna. The performance of a site, as judged by the NSA test, is considered acceptable when measured values are within +/- 4 dB of the theoretical ideal site values specified in ANSI C63.4. This validation procedure should be run once per year, minimum, for a standard OATS or semi-anechoic chamber and twice per year for weather protected OATS. While the transmission characteristics of a site are important, this one test does not adequately define the quality of a particular test site. The test repeatability, measurement accuracy and productivity at the test site will also depend on a number of other factors including the existing RF ambient and weather conditions.

Construction and Maintenance Costs

The initial lowest cost option for construction of a measurement site is a standard OATS. Generally a standard OATS only requires an obstruction free terrain and a mesh or metal ground plane. A weather protected OATS has the same basic features as a standard OATS but, is generally more expensive due to the additional costs associated with a type 1, 2 or 3 enclosure. Semi-anechoic chambers are the most expensive option in terms of construction costs due the costs associated with the need for a host facility, shielding, anechoic material, and fire protection.

Maintenance costs for an OATS depend on the weather conditions present at the test site. Because they are exposed to weather, equipment used to automate testing in a standard OATS (e.g., power sources, masts, turntables) need to be maintained on a regular basis. Type 1 and 2 weather protected OATS can have maintenance costs associated with removal of snow, ice, or water from the protective cover prior to testing. In addition, the RF transparent material used should be periodically cleaned to remove contamination such as airborne particulate material. Weather protected OATS also have the associated costs of more frequent NSA measurements (every 6 months) as recommended in ANSI C63.7-1992. The maintenance costs of a semi-anechoic chamber are essentially only the costs associated with the host building, maintaining the turntable and maintenance associated with cleaning and/or replacement of the finger-stock that creates the RF seal around the doors as well as the annual NSA testing.

Test Repeatability

Climate can affect radiated emissions measurements when testing is done at an OATS. Although many OATS may be covered so they can be used in any weather condition, variations in temperature and humidity can affect test repeatability. The construction materials used in the protective cover can influence test repeatability at a weather-protected OATS. Materials, such as painted or unpainted wood and nylon can retain moisture. Consequently, high humidity, recent rain or snow will affect the moisture content of the construction materials, thereby causing changes in the reflective properties, of the material, which in turn adversely affects test repeatability. Extreme temperature and humidity can also affect the operation of the EUT, especially for mechanical equipment. The operation of a printer, for instance, may be different in cold temperatures. Except for adverse weather conditions (snow, rain, etc.), changes in humidity and temperature will have relatively little effect on test repeatability in a standard OATS.

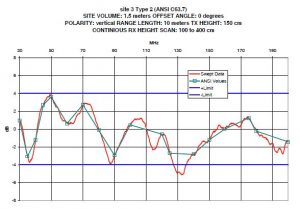

RF ambients can also affect test repeatability at standard or weather-protected OATS. Figure 2 shows the typical RF ambient that can be present at any OATS site.

A wide variety of test methods and protocols can be used to measure emissions in the presence of RF ambients, such as reducing the measurement bandwidth to separate the EUT emission from an ambient signal. Although reducing the receiver bandwidth is a common practice when working in high RF-ambient conditions, extra precautions should be taken to ensure the reduced bandwidth does not adversely affect the measured amplitude of the emissions from the EUT.

Test repeatability in semi-anechoic chambers housed in temperature- and humidity-controlled host facilities is generally greater than standard or weather-protected OATS. However, chambers employing open cell absorbers are more susceptible to variations in humidity than chambers employing closed cell absorbers.

Hybrid chambers – semi-anechoic chambers designed to operate below 1 GHz and up to 18 or 40 GHz – consist of two types of RF absorbing materials which are impedance matched or “tuned” to each other to reduce the reflection coefficient at the boundary between the materials. To achieve RF absorption performance below 1-1.5 GHz, ferrite tile is used. Foam absorbers are generally used for higher frequency ranges of 1 to 18 or 40 GHz, since using them for lower frequencies is impractical because their absorber profiles would have to be very large.

Foam absorbers (anechoic cones or wedges) are made from polyethylene, polyurethane or polystyrene materials. Each of these base materials has distinct advantages and disadvantages that can affect test repeatability. Polystyrene is a closed cell design that is unaffected by changes in humidity and therefore offer the most stable performance of the three types. Polyethylene and polyurethane materials are open cell materials similar to a sponge in the sense that they allow air to pass through the cells, or “breathe.” Consequently, even small humidity changes within a chamber can adversely affect the reflective properties of the polyethylene and polystyrene based absorber thereby degrading test repeatability. While polystyrene-based absorber designs offer improved test repeatability and increased physical endurance, they generally incur a higher initial cost than either polyethylene or polyurethane base absorbers.

Measurement Accuracy

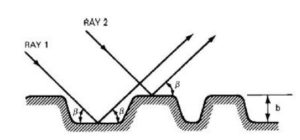

Measurement accuracy of any measurement site will be effected by the quality of the ground plane. ANSI C63.7-1992, Annex B recommends smoothness based on the Rayleigh criterion. This mathematical criterion illustrates the fact that the less flat the ground plane is, the more phase cancellation can occur. This criterion defines the size of the valleys that will not significantly impact measurements of radiated emissions. The Rayleigh criteria is defined as:

Special consideration must be given to the ground plane of an OATS that must be constructed to account for ground plane shift as a consequence of erosion. Ground planes in Type 2 and 3 weather-protected OATS are also more susceptible to weather conditions since they are exposed. Semi-anechoic chambers and Type 1 weather-protected OATS provide protective covering for the ground plane. The desired flatness is more likely to be achieved in a chamber than at an OATS because the ground planes in semi-anechoic chambers are made of machined components.

Special consideration must be given to the ground plane of an OATS that must be constructed to account for ground plane shift as a consequence of erosion. Ground planes in Type 2 and 3 weather-protected OATS are also more susceptible to weather conditions since they are exposed. Semi-anechoic chambers and Type 1 weather-protected OATS provide protective covering for the ground plane. The desired flatness is more likely to be achieved in a chamber than at an OATS because the ground planes in semi-anechoic chambers are made of machined components.

Measurement accuracy of a test site will depend on a variety of factors including measurement instrument accuracy, quality of the ground plane construction, potential weather related reflections (objects or enclosures near the OATS), RF ambients (at OATS) and the test procedures used to contend with those ambients.

Any object in the vicinity of an OATS (see Figure 1) has the potential of adversely affecting the accuracy of measurements taken at an OATS. Moisture buildup can cause surfaces on protective enclosures at Type 1 and 2 weather-protected OATS to become more reflective, significantly altering measurement accuracy. Measurements made during or immediately following adverse weather conditions (e.g., snow, rain, and high humidity) can be significantly affected by the presence of moisture on enclosed materials or any other object in the vicinity of the OATS.

Semi-anechoic chambers inherently have some reflections from the anechoic material since the absorbers are not perfectly lossy dielectric materials. However, these reflections are constant and can therefore be measured and accounted for during the normalized site attenuation testing. And, unless chambers are exposed to high moisture content, their performance should remain relatively unaffected, particularly in chambers where closed cell absorbers are used.

Making reasonably accurate measurements in the presence of RF ambients at standard and weather-protected OATS also requires thorough measurement protocols, including testing at different times (often late in the evening) when occurrence of RF ambients may be reduced. Other options include changing measurement distances, receiver resolution bandwidth, etc. Even with these extra steps, if the emission is too close to the RF ambient, it still may not be possible to measure with any reasonable degree of confidence at that particular OATS.

One of the most critical steps in accurately measuring emissions in the presence of RF ambients on an OATS is the implementation of preliminary measurements performed in an enclosed, semi-anechoic pre-compliance chamber or at a greatly reduced distance (e.g. 1 meter) on an OATS. The EUT is commonly tested first in a pre-compliance 3-meter chamber, where a “qualitative” emissions measurement is taken, or at a greatly reduced distance (e.g., 1-meter) on an OATS. This catalogs the EUT emission frequencies to be measured in the final “quantitative” EUT compliance test to determine if the emissions exceed the permitted limit. Any difficulty in discriminating emissions from RF ambients present during the preliminary measurements at an OATS usually results in those emissions not being measured at all.

Site Productivity

Site productivity is often measured by the number of tests completed in a day, and is dependent upon the measurement procedures used, the hardware and in some cases the software being used. There are significant trade-offs between accuracy and repeatability, and site productivity. Most productivity losses can be attributed to weather-conditions and RF ambients present at standard and weather-protected OATS. In addition, procedures such as doing pre-scans in a compact chamber and conducting final measurements at an OATS can reduce productivity. However, any OATS employing thorough methods to ensure accurate measurements can usually complete an average of one RF emissions test during an 8-hour shift. Semi-anechoic chambers, by virtue of being an ambient free environment, are able to double that productivity.

Conclusion

Selecting an appropriate design when building a radiated emissions test site or selecting a suitable site requires careful consideration of several key factors including operating and construction costs, test repeatability, measurement accuracy and site productivity. Inherent trade-offs exist between initial costs and test repeatability, measurement accuracy and site productivity. There are also much more significant trade-offs at OATS between site productivity and measurement accuracy and repeatability than exist with semi-anechoic chambers. If you choose to use or construct an OATS, careful consideration must be given to the site maintenance and the measurement procedures employed and their impact on site productivity, measurement accuracy and repeatability.

References

1. ANSI C63.4-2003, American National Standard Methods of Measurement of Radio-Noise Emissions from Low-Voltage Electrical and Electronic Equipment in the Range of 9 kHz to 40 GHz.

2. ANSI C63.7-1992, American National Standard for Construction of Open-Area Test Sites for Performing Radiated Emission Measurements.

3. M. Windler, D. Camell. “Research on Site Qualifications Above 1 GHz.” Proceedings, 15th International Zurich Symposium on Electromagnetic Compatibility. Zurich, Switzerland. Feb. 18-20, 2003.

4. R. DeLisi. “Radiated Emissions Pre-Scanning … Where and how to make an accurate pre-scan.” CE Magazine, 2001 Reference Guide.

Authors

Bob DeLisi is the Principal Engineer for EMC at Underwriter’s Laboratories Inc. He has been with UL for 16 years. Bob has managed and helped design some of UL’s EMC facilities He participated on ANSI Accredited Standards Committee C63 and is the chair of Subcommittee 8, Working Group 2. He is also a member of IECEE’s Committee of Testing Laboratories Expert Task Force, CLT-EFT 10 for EMC. He can be reached at bob.delisi@us.ul.com

Michael J. Windler is the General Manager responsible for the operation of the EMC and NEBS laboratories of Underwriters Laboratories Inc. in North America. Michael has worked for UL since 1985. Mike has a BSEE, 1985, from the University of Wisconsin, an MBA, 1995, from Northwestern University and is a licensed Professional Engineer. Mike is a member of the IEEE and is a member of the American National Standards Institute Accredited Standards Committee C63. Mike has published technical articles on EMC measures and given presentations on EMC related issues at IEEE EMC Symposiums.