Philip F. Keebler, D. Michael Evans and Nathan A. Reid

KCE Engineering, LLC

Knoxville, Tennessee 37918

Introduction

The protection of equipment from threatening electrical disturbances that occur on the power grid and inside customer facilities and the protection of equipment from conducted disturbances (i.e., emissions) are critical to the life and operation of any electronic equipment. These are two issues for manufacturers that must not be taken lightly. Manufacturers are under continued economic pressure to design and manufacture equipment that must perform as their customer expect. Moreover, manufacturers have profit margins that must be met if they are to satisfy their investors and continue to develop new products for our digital society. Equipment failures and malfunctions caused by EMI problems and voltage surges can be dealt with in an economically effective way without compromising equipment protection or performance.

Two of the technologies that have grown to be commonly used in product design in the last few decades are passive EMI filters using primarily capacitors and inductors and metal oxide varistors (MOVs), respectively. EMI filters have been used much longer than MOVs. Many new topologies for EMI filters have been designed and implemented. Essentially all of them make use of additional filter components (i.e. capacitors and inductors) to form multi-stage filters. Thousands of new products routinely fail conducted EMI tests when trying to achieve US or international compliance as defined by rules and regulations attempting to avoid EMI problems. Each and every product designer can a “horror story” when trying to achieve EMC compliance. Forensic analyses of many failed products on the market today revealed that product failures were caused by early MOV failure. Many products also suffer from undetectable damage to EMI filters caused by improper or no protection of filter elements from voltage surges.

This article is not intended to dive into the technical details of EMI filter design, but is intended to begin presenting discussion regarding the business case as to why more effective filters are needed in product design. The authors include a discussion of how a new passive EMI filter technology can eliminate many of the challenges associated with the design and application of traditional EMI filters and the challenges associated with product testing. This new technology makes effective use of cancellation of emissions currents resulting in the need for only a small amount of dielectric material (i.e., making it essentially a dielectric-independent FILTER) and the elimination of the inductive element—the common mode choke. Future articles will present a few specific applications of the new filter technology including performance and economic analyses regarding the use of the technology in various types of electronic equipment.

Economic Pressures to Increase Equipment Performance and Compatibility

Equipment manufacturers are constantly looking for ways to reduce operating costs. The cost of product designs, testing and manufacturing equipment has become a heightened concern that must be re-evaluated in today’s economic times. The economic gains resulting from moving manufacturing lines overseas can no longer support the margins required to sustain profitable operations of manufacturing facilities in the United States. Moreover, the cost of customer service—maintaining, servicing, and honoring warranties—has become a larger financial risk that manufacturers cannot afford to leave to fate. The economics associated with applying the traditional approaches to move equipment from the “proof of concept” stage to cost-effective production inside the manufacturer’s facility through to its “end of life” on the customer’s floor can no longer support a health bottom line profit for manufacturers and their investors. End users are also demanding products that last longer with sustainable performance given the financial constraints of making the investment to purchase products in today’s economic times.

Product Designs

Product designers must spend their allotted design time applying their specific professional expertise on designing the core performance of their product. Core performance defines what their product is supposed to do for the customer. Does the product do the job fast enough and produce a high quality end result? Does the product perform without introducing errors into the final product? Is the product light enough? Is the product too large? For example, if the product is a high-definition flat screen television, product designers must spend their time focusing on picture and sound quality as well as ensuring that the functionality of the television meets the customer’s expectations. Designers should not have to waste time chasing emissions back to an ineffective EMI filter and trying to figure out why electrical noise might be affecting the picture quality. This is especially important when the noise is not originating in the digital circuitry needed to process the high-definition signals and apply them to the screen array. Designers will end up with better picture quality if they can work from a noise floor in their digital designs that is lower. Designers should ask themselves, “How many board-level noise suppression components are required versus signal shaping components that actually affect the signals that define the picture quality?” Better control of radiated and conducted emissions will significantly affect the noise floor on the printed circuit boards.

In another example, a product designer working on a communications link for a smart appliance such as a refrigerator must spend his or her design time on the quality of signal integrity and transmission of the link rather than chasing the source of emissions currents affecting the quality of the link and whether or not commands initiated by the user or by an energy management company properly invoke the functions necessary to operate the appliance. Traditional noise sources on printed circuit boards can generate emissions currents that travel through power, ground and signal traces that end up in the wrong places on printed circuit boards. Trying to mitigate these noise currents further away from their sources presents additional design challenges that end up taking additional board space and designer resources that could otherwise be attributed to components and design time affecting the core performance of the product.

Printed Circuit Board Layouts

The mechanics of printed circuit boards are critical to the frequency performance of any circuit and to the magnitude and phasing of voltages and currents for power and signaling that must be able to travel across boards. Lines on a schematic that connect components together to form a circuit are simple and easy to conceptualize when trying to design and understand how a circuit works. The mechanics of the board include the elements of resistance, capacitance and inductance of all the materials used in the board. This includes the copper traces and the board material. A copper trace has a distinct length, width, and thickness. These dimensions make up the resistance, capacitance and inductance of the trace. The distance between traces is also critical. There is a capacitance between the traces. The paths traces take from component to component also impact the magnitude, phasing, and frequency response. When the frequency of the voltage and current is low, the mechanics of the board does not play a critical role in how the circuit really works. However, as the frequency increases the mechanics of these elements becomes critical to the control of radiated and conducted emissions.

When a designer places a resistor in a circuit, for example, he or she desires that resistance at that location within the circuit. The same is true for other components like real inductors and capacitors. However, when two resistors are placed in the same path using the same copper trace, a small “inductance” then becomes a part of the circuit. The “inductance” is not a real inductor (or coil) like we know and see when we hold one in our hand, but it is a “parasitic” (or internal) inductance of the resistor. The parasitic inductance, like any other inductor, will become essentially an open circuit as the frequency through the resistor-parasitic inductance-resistor circuit increases until the two resistors are no longer electrically connected together. Of course, this is because the impedance (i.e., frequency dependent resistance) increases linearly with frequency. The impedance of an inductor is XL = j2πfL Ω (ohms) where f is the frequency and L is the value of the parasitic inductance. From this, one can see that as the frequency increases, so does the impedance. Also, as the inductance, L, increases, so does the impedance. Hence, designers want to keep the parasitic inductance as low as possible to ensure that the resistor-to-resistor circuit has as little inductance as possible.

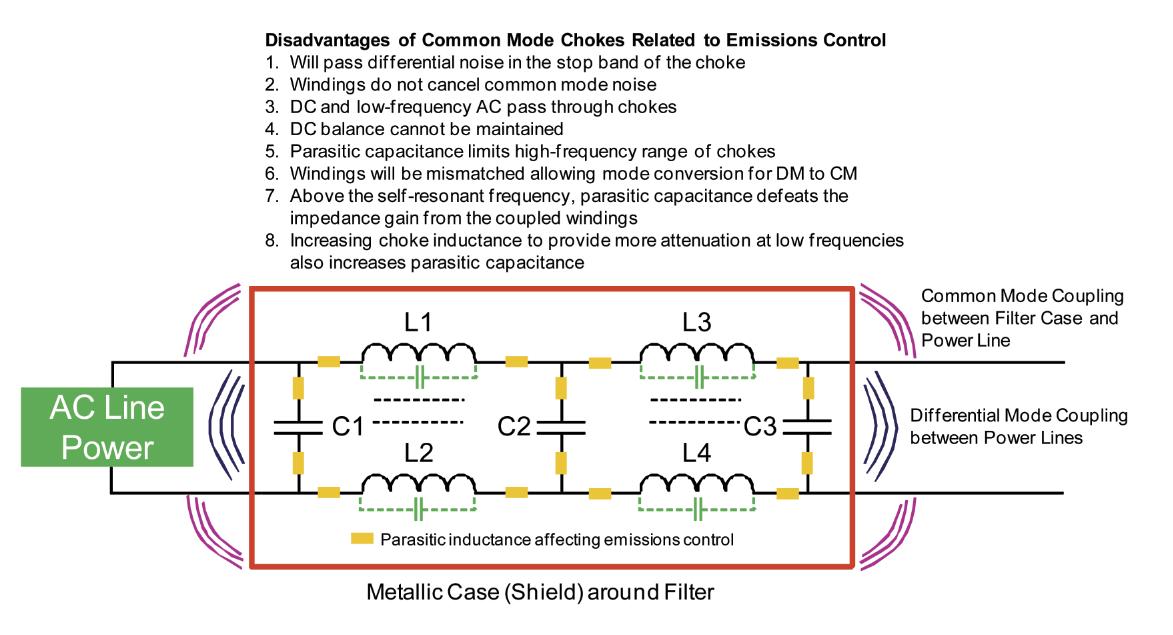

EMI filters by definition are designed to absorb (or soak up) and divert conducted emissions currents (i.e., electrical noise) generated by the operations of electronics downstream of the filter. Conducted emissions are very small voltage signals that create very small currents that “ride” on AC and DC waveforms. Emissions will “ride” on power and control signals in efforts to get outside of equipment seeking the lowest impedance possible. Emissions captured by a filter are injected into the ground conductor of the equipment. Emissions build up and circulate in the grounding system of a building. Conducted emissions must be controlled so that when the remaining emissions flow into the AC line cord, they have a much less likelihood of causing an EMI problem when they flow back into the wiring and grounding system of a building and onto the grid. While the magnitude of these emissions is low, the allowable limits for emissions on an AC line cord are low as well. Because of this, an EMI filter is designed to remove very small noise voltages and current but must allow AC (and DC in the case of DC sources and loads) power to flow from the grid to the electronics downstream of a filter. They must also be designed to “take the hits” from electrical disturbances (e.g., voltage surges and temporary over-voltages) generated by the grid and loads inside buildings. The nature of the design of traditional discrete EMI filters makes it difficult to control the emissions when discrete filter components (i.e., capacitors and inductors) are placed on a printed circuit board. Losses in each discrete component significantly affect the filter’s ability to reduce emissions. Filter designers must make these components large to overcome their losses. This makes filters large, heavy, and expensive. This is one reason why the parasitic impedances that are a part of traditional filters and their components can significantly affect how much of the emissions are filtered.

Figure 1: Disadvantages of common mode chokes and parasitics impacting the control of conducted emissions

Testing, EMI Line Filters and Emissions Performance

Manufacturers spend a tremendous amount of money having their products tested. Products must be tested for various purposes—safety, compliance, etc. Some manufacturers do pre-compliance testing in their own development laboratories in preparation for actual compliance testing where performance certificates are awarded. Whether time is spent on pre-compliance or compliance testing, that time costs manufacturers millions of dollars per year. One of the key sets of compliance tests that must be performed are the battery of EMC tests. Two primary groups of EMC tests that are performed on products are radiated and conducted tests. Radiated emissions travel from the components, circuit traces on the board and wiring into the air. Conducted emissions travel from the components, circuit traces on the board and wiring onto electrical conductors—the AC line cord and its ground conductor, data and network cables, and control cables.

Radiated and conducted emissions are linked together by the laws of physics. They significantly influence each other as Maxwell’s equations predict. Their influence presents key concerns when emissions suppression devices (i.e., filters) are used anywhere on the board, inserted in a conductor, or around a component or product. This influence can easily degrade the performance of a filter whether the filter is a discrete design mounted on a board without the use of a shielded can or a shielded design where its components are placed inside a shielded can placed on top of a board or on the side wall of an equipment enclosure. When a shielded can is used, emissions on the equipment side of the filter can leak around the filter can. This leakage is influenced by the use of ground conductors inside and near the filter can and by other metallic objects around the filter can. Leakage can also occur across filter components like common mode chokes whether the chokes are inside a can or mounted directly on top of a board. Leakage of emissions is one cause of failure to achieve compliance with conducted emissions limits that designers often overlook.

Too often, manufacturers must have safety and compliance tests repeated. Repeat testing is a significant expense for the product testing budget. When traditional EMI filter technologies are used, repeat testing is necessary because a product did not pass a test the first time. Many products simply do not pass the tests even the second or third time. While some may say that passing a test the first time is not realistic, careful design practices can reduce testing time and costs. A careful design approach takes into account all of the factors that influence emissions control including board-level components not associated with the EMI filter as well as the design and implementation of the most effective filter for the application and the desired level of emissions control (i.e., meeting the conducted emissions limits of interest).

Common Mode Insertion Loss

Common mode insertion loss is a measure of the loss that the common mode function of a filter element applies to the conducted emissions profile. Loss at the right frequency range must be applied to the emissions currents generated by the electronics inside the equipment to reduce their magnitude before being allowed to travel outside of the equipment on the AC line cord. Emissions currents that flow from inside the equipment through one line conductor (e.g., hot) back through ground and from the equipment through the other line conductor (e.g., neutral) back through ground share the ground conductor as common. This gives rise to the name common mode emissions. Because most EMI problems are caused by common mode emissions, this metric is important in predicting the performance outcome of an EMI filter.

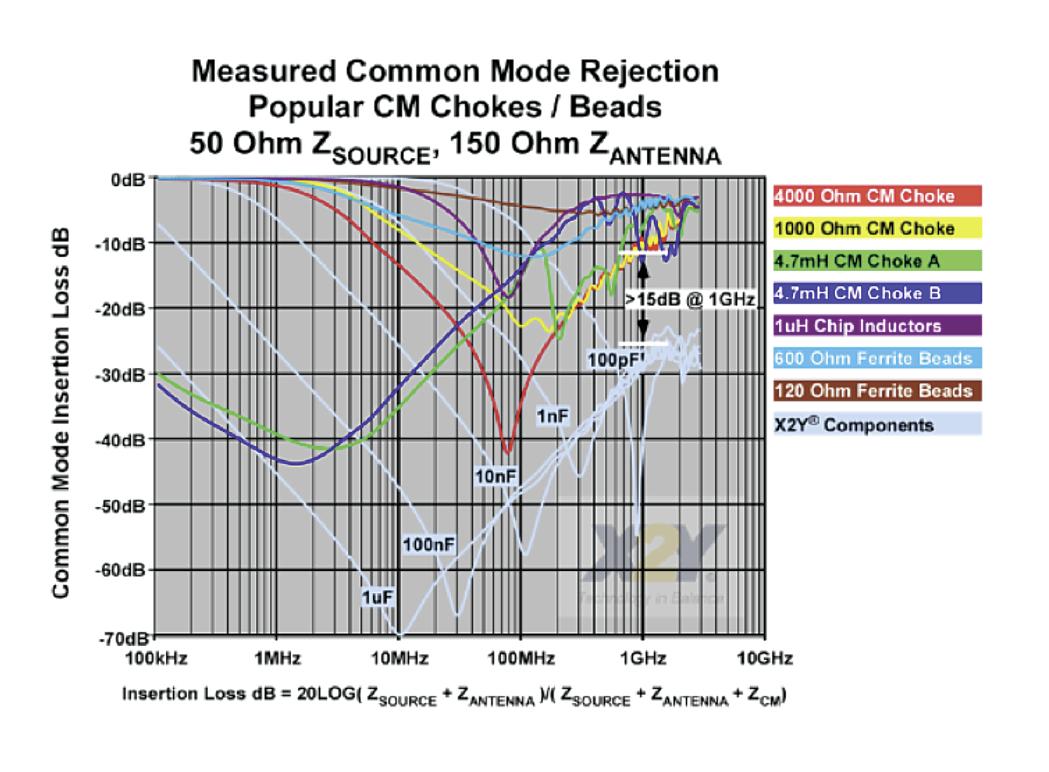

Figure 2 illustrates this loss as a function of frequency from 100 kHz to 10 GHz for eight different cases of EMI filter components. Four of the cases use typical common mode chokes found in many of today’s EMI filters used in end-use products. One of the cases is for a chip inductor used on a circuit board. Two of the cases are for ferrite beads used on circuit boards or on individual conductors. The last case represents the improvement in loss for five different capacitance cases where the new EMI filter technology is used. One will notice from the graph that the loss is significantly improved over each of the comparison cases. The improvement in loss is not only important at the lower and middle frequencies but also the high frequencies in the GHz range. An increasing number of consumer products now use on-board wireless radios operating in the low (e.g., 1 to 6) GHz range. These high-frequency signals have been found in the conducted emissions profiles (i.e., test results) of many products. Take the example case of the 1 GHz signal shown in the graph where the use of traditional elements used in today’s filter designs only provide about 10 dB of loss whereas the new filter technology can provide almost a 20 dB improvement in loss. This improvement will help keep GHz-frequency components off the AC power line and increase the performance of wireless-based products.

Figure 2: Common Mode Insertion Loss for Traditional Chokes vs. Chokeless Dielectric-Independent Filter Component

Two Basic Filter Types and Filter Components

In trying to meet a set of compliance limits for conducted emissions testing, the obvious system or device inside the product that affects emissions control is the EMI filter. Product designers choose between two approaches for their EMI filters—discrete designs or shielded can (i.e., one-piece) designs. With discrete designs, each component of the EMI filter is individually placed on a dedicated circuit board or on a circuit board with other components (e.g., power supply components). Discrete filter designs typically range from the simple filters that use anywhere from four to five components to the more complex filters that use up to twenty components. Each discrete filter component is connected to the other by use of copper traces on a printed circuit board. The design of the traces is also an important factor that influences how the filter performs and the product’s emissions control. Traces play a key role in leakage and coupling. The coupling between components and the traces on the board is the vehicle that allows the emissions leakage to occur.

In a shielded can design, each filter component is electromagnetically shielded from the electromagnetic environment outside the can by the metallic material forming the shield. The shield must be grounded to the equipment ground. This helps keep the buildup of charge off of the shielded can and helps to ensure the can acts like a shield against electric fields that make up the emissions. However, the methods of grounding the filter can and the interface between the ground conductor on the board and the can heavily influence the emissions performance.

Whether the filter is made of discrete components placed on a board or a system of components on a small board placed inside a shielded can, a specific arrangement of capacitors and inductors are used to make up the filter. Other components like fuses, thermal protectors, and even MOVs may be used inside a filter can to provide a more complete solution for product designers. Many standard filters use only one inductor (common mode choke) and two across-the-line (X) capacitors—one upstream of the choke and one downstream, both of which take up a considerable amount of board space and space inside a can. This type of filter is called the pi-type filter. Many filters also use one or two line-to-ground and line-to-neutral capacitors (Y). There are limitations as to how much Y-capacitance can be used in a filter. These limitations are based on the amount of allowable leakage current that can flow from the filter to the ground. Leakage current represents the noise current captured by the filter and injected into ground.

Filter and product designers are moving towards the use of more complex filters. This is because electronic loads are becoming noisier—generating higher levels of conducted emissions. The use of more complex filters is also attributed to tighter emissions control defined by lower conducted emissions limits. Standards in the US are slowly becoming more stringent as the harmonization of standard around the world continues to take shape. However, the limits imposed by European and Asian countries are much more stringent in efforts to further reduce the likelihood of a product causing an EMI problem. Complex filters use more than one inductor and multiple X- and Y-capacitors. These filters even use capacitors in other arrangements around the inductors and X- and Y-capacitors. Complex filters are used simply because the amount of loss that can be provided when using simple filters cannot be achieved.

Off-the-Shelf EMI Line Filters

Some product designers elect to use off-the-shelf filters. These filters are predesigned and require the use of a shielded can to hold the filter components in place. Off-the-shelf filters are a large market for all filter manufacturers. In many cases, when a product that uses an off-the-shelf filter that fails a conducted emissions test, then another off-the-shelf filter is quickly pulled from a “convenient” batch of filters located at the EMC test house. The objective here, of course, is to very quickly find a filter that will provide a passing test result for the conducted emissions test. While this approach may very well serve the purpose and provide that passing test result, it can also precipitate the use of a filter that is insufficient in some way or a filter that is overkill is some way. There are many factors that should be carefully considered before an off-the-shelf filter is selected for use in a product.

In addition to insertion loss (if it is even known), attenuation, steady-state voltage rating, and steady-state current rating, other factors are also critical to the performance and life of the filter. For example, what are the transient voltage ratings for the front-end capacitors inside the filter? How much transient energy can they handle before they begin to suffer damage and eventually fail? How does the product designer know that any one of its customers’ facilities will not be subject to voltage transients that will start degrading the reliability of the capacitors used inside the filter? How much non-linear distorted AC current does it take to cause the common mode choke inside the filter to go into saturation? Does the product generate a lot of non-linear distorted current that will affect the performance of the filter? Will the filter suddenly reduce its effectiveness when the product is switched into a different operating mode requiring a higher level of distorted line current? How does the filter performance vary with input impedance and output impedance variation? These are all important to the successful implementation of any EMI filter used on the AC line for the product.

Another challenge that presents difficulty in using off-the-shelf filters is the amount of space available on the board and inside the product to locate the filter. In many instances, the substitute filter selected from off-the-shelf is just too large to fit into the intended space where the original filter was designed to fit. This problem can cause a complete redesign of the circuit board which can introduce a whole variety of other problems (including the degradation of any emissions control already achieved)—problems that continue to eat into the product development and testing budgets which manufacturers try to control.

Some manufacturers who took this approach later found themselves with failed products—failures that were caused by the use of improperly specified (and selected) EMI filters. Regardless of what caused the product to fail, a filter failure is still a product failure to the customer. These pitfalls can be avoided if care is taken in the selection of which type of EMI filter to use in a product.

Manufacturing

The cost of manufacturing a product is always one of the top concerns for manufacturers. Many production lines have already been moved to overseas factories. In many cases, product warranty claims are increasing beyond expected levels. In other cases, there is just nothing left to “squeeze” out of the product budget to sustain planned profits. Further reduction in product costs must be achieved using some other cost control approach in order to boost the struggling economy of today. The invention of automatic insertion machines that use robotics to pick up small components and carefully place them in the right location on a circuit board is one excellent example of cost control that has definitely saved manufacturers millions of dollars in labor costs. Unfortunately, this approach also reduces jobs. However, many large bulky components like EMI filters still have to be placed on boards by the human hand. This is an expensive labor component for manufacturers to have to endure.

Two commonly used components in EMI line filters that in many cases must be hand inserted are across-the-line (or X) capacitors and common mode chokes (or coils). Both of these components can be large and bulky depending upon the size needed. In many cases, multiple common mode chokes must be used in multi-stage filters to introduce enough attenuation to achieve the desired level of emissions control. The amount of loss associated with the components used in filters is so large that the components must be oversized to provide the desired attenuation. Common mode chokes are also heavy, use large magnetic cores and lots of copper wire. In addition, product designers must be on constant watch for reaching an operating condition that causes the wire temperature to reach unreliable levels. The use of these chokes also affects product efficiency and increases product operating temperature. Eliminating the use of the common mode choke in EMI filters is a huge step forward in filter design and offers many benefits. Table 1 summarizes the disadvantages of common mode chokes and the advantages of dielectric-independent filters.

Table 1: Comparison of Basic Attributes for Common Mode Choke and Filter with No Choke

|

Attribute |

Common Mode Choke (Use of Traditional EMI Line Filter) |

No Common Mode Choke (Use of Dielectric-Independent Filter) |

|

Size |

Large |

Small |

|

Weight |

Heavy |

Light |

|

Auto-Insertion |

Not possible |

Possible with most filters |

|

Materials |

Copper and Core Material |

No copper |

|

Cost |

High |

Low |

|

Reliability |

Low |

High |

|

Assembly Cost |

High |

Low |

|

High-frequency Performance |

Poor |

Superior |

|

Failure Modes |

Vibration, Over-current |

Over-voltage |

|

Line Current |

Must pass through coil |

Only passes through straight line pins |

|

Temperature |

Hotter |

Cooler |

Maintaining, Servicing and Warranties

Every product manufacturer must be able to provide a variety of customer services which include maintaining, servicing and warranting their products. The quality of power inside customer facilities affects the level and cost of these services provided to the customer since power quality directly impacts equipment performance. Common everyday electrical disturbances cannot be avoided despite the mission of utilities to provide better power quality. Weather patterns are changing significantly creating more frequent lightning strikes and natural disasters that impact the grid. Traffic accidents involving utility poles will always occur. More vehicles are being placed on the highways and roads. Animal control is always a struggle for utilities to keep squirrels, snakes, and rodents off transformers and hot conductors. Construction crews will always dig into the ground to install new infrastructures to find that their digging equipment has penetrated a power line duct. Other utility customers on the same power feeder or substation will always turn on large loads without notifying the utility. These events are beyond our control and will continue to introduce destructive electrical disturbances into the electrical systems and electronic equipment that customers depend on.

Owners of large pieces of equipment like medical imaging systems (e.g., MRI, CT, X-ray, etc.), adjustable speed drives, and copy machines will always be entered into some type of maintenance and service contracts to keep their equipment operating. Manufacturers who offer such services and service companies who are in agreement with their customers to honor these contracts must investigate equipment failures and malfunctions when their customers call. Quite a few instances involve some electrical disturbance that occurred on the building electrical system which caused equipment to fail or malfunction.

Sudden equipment failures typically involve the occurrence of voltage surges or temporary over-voltages which can damage some internal components of the front end AC line network used to protect the equipment. Surges and over-voltages can originate outside and inside a customer facility. Malfunctions typically involve some type of intermittent or recurring disturbance that causes the power supply inside the equipment to react unfavorably producing some type of DC disturbance on its output bus. High-frequency events and electrical noise can also occur on a building electrical system creating an EMI problem for the equipment.

Traditional EMI filters in older equipment still in operation may be able to mitigate a conducted disturbance ranging between 450 kHz to 30 MHz. Most new electronic loads on the grid today must meet emissions control down to 150 kHz. With the growing population of wireless devices and the increase in the wireless frequencies, new emissions control requirements will continue to reach higher frequencies well beyond what they to today. One goal of regulating emissions near and above the 1 GHz point is to maintain control of wireless signals on the AC line cord.

Disturbances that occur outside of this range may survive a trip through the filter to critical electronics inside the equipment with a high enough magnitude to cause severe malfunctions. Traditional EMI filters will not provide protection against most of the voltage surges occurring in today’s electrical environment. Across-the-line (or X) and Y-capacitors (line to ground and neutral to ground) capacitors can suffer silent damage when voltage surges occur. Eventually, if the surges continue, then these capacitors will fail. The International Electrotechnical Commission (IEC) reported in 2005 that products using EMI filters being returned to manufacturers to find that the emissions levels had increased by as much as 55 dBuV. (This is a factor of 562 µV increase in noise voltage.) When such filters failed, the products continued to work with no problem except for the fact that they were injecting large levels of conducted emissions into the building electrical system. Some of the products were reported to have caused severe EMI problems with other equipment inside the buildings where they were found.

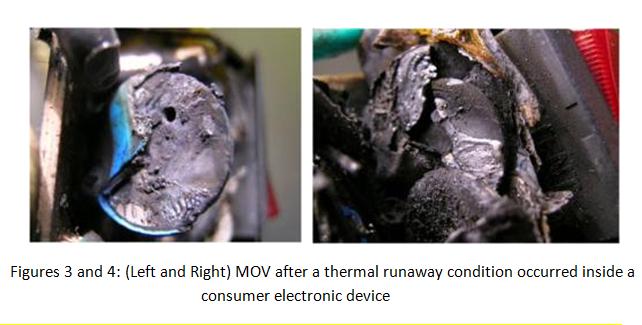

The dielectric-independent filters that use no common mode chokes and very small X- or Y-capacitors do not suffer from these problems. These filters do use a small amount of capacitance (typically in the 1,000 to 4,000 picofarad range) around each straight line pin conductor that supports the flow of AC line current through the pin. This little amount of capacitance is the only amount needed to actually provide the level of filtering needed to reduce unacceptable levels of conducted emissions. In addition, the capacitive material used around each pin has an inherent transient voltage clamping capability that acts as an internal surge protector with no metal oxide varistor (MOV) material used. The capacitive material may be removed from the filter design and substituted with an MOV material to increase the level of voltage withstand capability for surge protection. In either case, this means that no discrete MOV is needed external (upstream, downstream, or in some cases in parallel with the choke) to the filter. The elimination of a discrete MOV on the printed circuit board eliminates the failure (e,g,, thermal runaway discussed in more detail below) associated with board-mounted MOVs. These failure modes have been a growing concern to product designers for years. This mode is associated with the thermal runaway of an MOV that occurs when the AC line voltage creeps up to some value above nominal (e.g., 120 volts). The more typical MOV failure mode associated with just wearing out the MOV from repeated absorption of surge energy is also significantly reduced.

When manufacturers offer warranty programs for their products, they allocate a budget for those programs. The budget is based on an expected amount of failures given some knowledge of the performance of the equipment and a past history of failures of similar products. The questions here are “How does the knowledge of the electrical environment (or power quality), or the lack of knowledge, enter into the design of the manufacturer’s warranty program? Are all of the electrical disturbances that do occur on the grid and inside a customer’s facility taken into account when the warranty program is designed? Is the manufacturer experiencing any increase in failures associated with common everyday electrical disturbances? How is the manufacturer planning for a sudden increase in thunderstorms that will cause a sudden increase in equipment failures caused by lightning strikes to the grid, to the utility power distribution systems, and to customer facilities? Does the manufacturer really know the reliability of the surge protection devices (and the filter components) they use inside a piece of equipment in today’s current electrical environment? Does the manufacturer need to reduce the number of warranty claims? Does the manufacturer really know the real cause of equipment failures that are logged under warranty claims? How many of these claims are related to power quality and to the level of surge protection provided by the present surge protection devices (discrete MOVs) used in their equipment designs? Can the number of warranty claims be reduced by employing a different type of EMI filter with integral surge protection instead of using discrete MOVs on the board.

Safety

There is no question about it—safety is of primary interest to manufacturers in the design and operation of their equipment. The use of AC line power to operate electronic equipment does present some safety concerns for customers. Leakage current is produced and can flow off the frame of equipment through the human body. Safety engineering experts have been concerned about this for years. Designers must strive to reduce the risk of electrical shock and fire caused by the operation of their equipment on the utility grid and inside customer facilities. Effective grounding and the reduction of leakage current has taken the lead in many design topics associated with safety for decades.

The fact that electrical disturbances do occur on the grid and make their way into customer facilities and electronic equipment does increase the risk of causing an unsafe condition to develop when electronic equipment is used in the presences of humans. Electrical shock from the flow of 60-hertz current through the human body has been a safety subject studied for years. Safety agencies and organizations have put standards and requirements in place to limit the flow of leakage current from an electronic load. The amount of leakage current from the 60-hertz (or power line frequency) component of ground current is a measurement requirement in safety standards for equipment. Any current that can flow from a grounded surface of a piece of equipment or a ground conductor connected to the equipment contributes to the total leakage current.

The capacitors inside EMI filters that are connected from line to ground and neutral to ground are significant contributors to leakage current. These capacitors allow currents at all frequencies with the emissions profile to flow, not just the 60-hertz components. One key disadvantage of traditional EMI filters is the presence of these capacitors in these filters and their effect on the magnitude of leakage current. In the dielectric-independent filter technology, there is a capacitance between the line and neutral. Part of that capacitance can be seen from line to ground and from neutral to ground. The advantage here is that this capacitance is very small and on the order of a few thousand picofarads or less. Thus, the contribution to leakage current from these capacitors to ground is much smaller when the dielectric-independent filters are used as compared to the larger (typically microfarad sized) across-the-line (X) and line-to-ground (Y) capacitors used in traditional EMI filters.

Another very important aspect of safety for circuit protection devices is the prevention of thermal runaway. Figures 3 and 4 illustrate examples of a metal oxide varistor (MOV) that experienced thermal runaway and ignited. These MOVs were discrete devices mounted directly on top of the circuit board with no protection over the body of the MOV. Thermal runaway occurs when the AC line voltage creeps up to a value over the maximum continuous operating voltage (MCOV) rating of the MOV. MOVs can be subjected to many high currents caused by voltage surges. This exposure which can occur in any real electrical environment causes MOV aging. In environments where surges are known to occur more frequently, premature aging can occur. Aging results in a lowering of the MCOV level. When the MCOV level is compromised, even acceptable levels of line voltage within industry standard limits can create a thermal runaway condition causing a flame and smoke on the printed circuit board. Some MOV manufacturers design their MOVs to withstand repetitive surges, but premature MOV aging can still occur in surge-rich environments—geographical areas where lightning frequently occurs and on utility feeder circuits supporting customer loads that can generate potentially high surges.

Recent power quality testing and research carried out in the past ten years on end-use equipment using MOVs and surge protection devices used in panel-mounted protection devices (e.g., surge protection modules mounted outside of a panel and encased in modules designed to be mounted in a circuit breaker slot) and power strips generated data supporting revisions to the UL 1449 – Standard for Safety for Surge Protective Devices. This resulted in new requirements for product designs to use MOVs with 130-volt MCOV ratings when equipment is designed to operate at a nominal line voltage of 120 volts. MOVs with a 150-volt MCOV rating are also available today to account for a ± 10% swing in utility line voltage specified in ANSI C84.1 (2011) – Electric Power Systems and Equipment – Voltage Ranges which nearly all US utilities follow. Although 130-volt and 150-volt MOVs cost the same, some product designers still prefer to use MOVs rated at 130 volts for the MCOV. Higher cost MOVs are available today with built-in thermal protection. Unfortunately, when an over-temperature condition is detected, the thermal protection device permanently opens one leg of the MOV removing it from the circuit. This results in the MOV being taken out of the AC line circuit, thus leaving the equipment unprotected from surges and over-voltages that occur on the AC line.

In the dielectric-independent EMI filter, much less MOV material is used internal to the filter than is used in a discrete surge protection device. In addition, the MOV material is physically protected by potting material poured around the MOV material. Further protection is provided by the electromagnetic shield that forms a complete metallic enclosure around the EMI filter. With these design characteristics, the MOV material is much less likely to become a safety concern when the AC line voltage exceeds its MCOV rating. This will allow manufacturers to avoid the use of the discrete MOV mounted in open air on the circuit board, thus providing their customers with safer surge protection inherent to the EMI filter without the risk of flame or smoke. The potting material injected around the MOV material surrounded by the metallic enclosure will increase the rate of heat transfer out of the MOV material. Testing is currently being carried out to determine this. MCOV testing can be carried out at surge currents as high as 1,000 amps.

Growing Threats in the Electrical Environment

Threats in the electrical environment that impact the performance of electronic equipment continue to increase. This is not because the generation, transmission, and distribution of power is getting worse (yes, the grid is aged and continues to age). Threats continue to increase in both severity and frequency because the exposure of the grid and customer facilities is increasing. How does the exposure increase? This is answered by the events that occur around the power system and inside customer facilities that affect the power system and the quality of power inside customer facilities.

There are a number of events that continue to occur that cannot be controlled that are increasing the risk of damaging electronic equipment. Moreover, society is demanding and placing more electronic equipment in the electrical environment. Most of this equipment is being placed in areas where it is exposure is on the increase like in remote areas away from facilities closer to the utility power distribution system. End users want the modern conveniences at their fingertips. One example is the growth in the number of automatic teller machines (ATMs) in the last few years and the growth in the number of vending machines that provide users with compact video discs. Another example is in the growth of electronic lighting devices placed in customer facilities followed by these devices being placed outside on the sides of buildings and on utility power poles. Electric vehicle chargers are also being installed in a number of places remotely located to customer facilities. The growth in the number of red light cameras being placed at busy intersections is another prime example in the increase of electronic loads which are exposed to threatening electrical disturbances closer to the grid. All of these remote loads require electrical cables (power, control and signal) be buried underground. Running these cables underground forms loops which act as “collectors” of harmful voltages induced by high currents that flow underground when lightning strikes.

The growth in the number of distributed generation resources—wind turbines, microturbines, fuel cells, and photovoltaic (PV) solar systems—is causing an increase in the level of radiated and conducted emissions that impact the operation of electronic equipment on the grid and inside customer facilities. Utilities are installing millions of solid-state (smart) revenue meters to electronically record the amount of electrical energy used at each customer site. These meters can also be used to control loads inside the facility as well as report back the usage and demand data. Severe cases of EMI between solid-state meters and PV systems have already been reported in four European countries followed by several similar cases in the United States. The use of more effective circuit protection devices like dielectric-independent EMI filters with integral surge protection will increase the amount of protection provided to electronic equipment as well as decrease the threats that are caused by electronic equipment connected to the same voltage buses inside customer facilities.

The electrical environment inside customer facilities is becoming a higher exposure environment for electronic equipment as well. Many facilities are installing adjustable speed drives which increase the level of radiated and conducted emissions as well as continual degradation in the quality of the line voltage powering electronic equipment such as motors used for heating, ventilation and air-conditioning inside customer facilities. The growth in the installation in other electronic switching loads that generate electrical disturbances is on the rise as well.

Standards

An array of EMC standards exist today to limit the level of radiated and conducted emissions generated by end-use electronic equipment. The limits in the standards in use today were based on philosophies developed decades ago. The limit standards in place in the United States are not near as stringent as the standards developed for member countries of European Union and other international countries. Many small signal engineers know the benefits of limiting the level of radiated and conducted emissions generated inside a piece of equipment that gets out onto the AC power line and onto data, network and control cables exiting the equipment. Signal-to-noise ratio is critical to the operation of many types of end-use equipment like electronic medical equipment designed to measure very small signals from patient–connected probes. Conducted emissions that are allowed to flow on the AC power line and through the equipment ground will impact the signal-to-noise ratio and the integrity of any small signal.

Researchers have studied and collected thousands of cases of EMI involving end-use equipment that were found to meet existing limit standards. Research must continue into the development of more stringent limits that can further improve the performance of end-use electronic equipment to combat the growing energetic electromagnetic environment. While the degree of improvement needed in limits is not yet known for most industries, researchers and product designers do agree that more stringent limits are needed to improve signal integrity and avoid an array of EMI problems as more electronic equipment comes on line in our modern digital society. The increased use of communications and connectivity to control end-use equipment and monitor the condition of the grid and the load it must support warrants the need for more stringent limits on radiated and conducted emissions.

The new IEEE 1560 standard, IEEE Standard for Methods of Measurement of Radio-Frequency Power-Line Interference Filter in the Range of 100 Hz to 10 GHz published in 2005 by the IEEE defines new test methods for measuring the insertion loss and other critical parameters associated with defining the performance of power line filters. One application of this standard that is gaining momentum is the generation of insertion loss data for traditional EMI filters. This is helping manufacturers to understand the real difference in performance for their products when they are placed in today’s electrical environment. This gives rise to the importance of losses in filters and the parasitic elements in filter components that “work against filter performance” causing filters to be larger and heavier than needed. This also increases the focus on filter cost and emissions testing costs. The IEEE 1560 is also being applied to the dielectric-independent EMI filter to further gain insight to its performance comparison against traditional filters.

The development of other standards such as the basic EMC immunity standard IEC 61000-6-19 is under draft development by the IEC. This new standard will defines the test method for performing conducted disturbance immunity testing in the frequency range from 2 kHz to 150 kHz is helping to make a case for the continued control of emissions and EMI problems. This development of this standard now in progress was largely fueled by the need to avoid conducted EMI problems involving solid-state meters, specifically those EMI cases where conducted emissions in this frequency range generated by PV inverters were causing EMI problems with solid-state meters. Without the application of higher performance EMI filters like the dielectric-independent filter, it will be even more challenging to control conducted emissions in the 2 kHz to 150 kHz range and other ranges as well using traditional EMI line filters.

Research must continue on the use of integrated solutions used as integrated circuit protection devices like EMI filters, surge protection devices, current limiting devices, and thermal protection devices. This will allow protection devices to work more effectively and efficiently. Moreover, this approach will precipitate one of the most significant reductions in equipment failures and warranty claims; thus increasing the bottom line for manufacturers and their investors.

Conclusion

Today’s EMI filters used on the AC power line to limit conducted emissions from end-use equipment are based on traditional filter designs that are years behind in design advancement. These historical designs continue to cost manufacturers millions of dollars in lost profits, limit equipment performance and allow equipment failures and malfunctions to occur that should be avoided. Settling for emissions control that is “good enough” will not allow manufacturers and end users to realize the benefits in equipment uptime and performance needed to sustain our digital society in the next few decades. End-use equipment is becoming more sophisticated and intelligent and necessitates more stringent control of conducted emissions and immunity. Products that use wireless radios will benefit from the use of new filter technologies in keeping the wireless signals off of the AC power line. Research is being conducted by the EMC engineering group at KCE Engineering, LLC located in Knoxville, Tennessee. Manufacturers who are interested in participating in this research can contact one of the authors of this article for further details.

About the Authors

Philip F. Keebler, MSEE: Keebler is a principal engineer at KCE Engineering. Mr. Keebler is an 18-year veteran of the Electric Power Research Institute (EPRI). While at EPRI, Mr. Keebler conducted EMC research on end-use products and power line filters. While there, he was one of the key authors of the new IEEE 1560 standard, IEEE Standard for Methods of Measurement of Radio-Frequency Power-Line Interference Filter in the Range of 100 Hz to 10 GHz that defined new test methods for measuring the insertion loss and other critical parameters associated with defining the performance of power line filters. Today, Mr. Keebler is a partner in the KCE Engineering, LLC firm located in Knoxville, Tennessee. One of the areas of focus at KCE Engineering is the specialization in EMC research on end-use equipment and in electromagnetic environments. Mr. Keebler can be reached at pfkeebler@kceengineeringllc.com.

D. Michael Evans: Evans is a Vice President of Technical Services at KCE Engineering. One of his areas of focus at KCE is in EMC research studying emissions profiles and the factors that influence these profiles caused by the operation of end-use equipment. Mr. Evans is also studying the application of EMI line filters in consumer, commercial, and industrial products including the design variables for filters and on printed circuit boards that affect filter performance and the reliability of end-use equipment. Mr. Evans can be reached at dmevans@kceengineeringllc.com.

Nathan A. Reid: Reid is Laboratory Manager at KCE Engineering. He is an engineering student-in-training at KCE Engineering. He is studying the application of the IEEE 1560 and new test methods associated with the measurement of conducted emissions and other performance variables regarding EMI line filters. Mr. Reid can be reached at nareid@kceengineeringllc.com.