Jason Smith, Manager Applications Engineering; Pat Malloy, Sr., Application Engineer; AR/RF Microwave Instrumentation, Souderton, Pennsylvania, USA

Given the huge amount of time required to conduct a radiated immunity test, it is no wonder operators “dream” of ways to improve efficiency to speed up the test. The musings generally go as follows:

-

Can one antenna cover the entire frequency range?

-

Can RF switching be automated?

-

Let’s add a controller to automatically switch antenna polarizations or even go as far as automatically turning the EUT to expose all four sides to the RF field.

-

What if we could speed up the dwell time just a hair without compromising the test?

While all of the above thoughts are useful, they only decrease transition times, which unfortunately comprise only a fraction of the total test time. What if there was a way to dramatically reduce test time while still meeting the stringent requirements of the test standard? This would certainly be a dream come true.

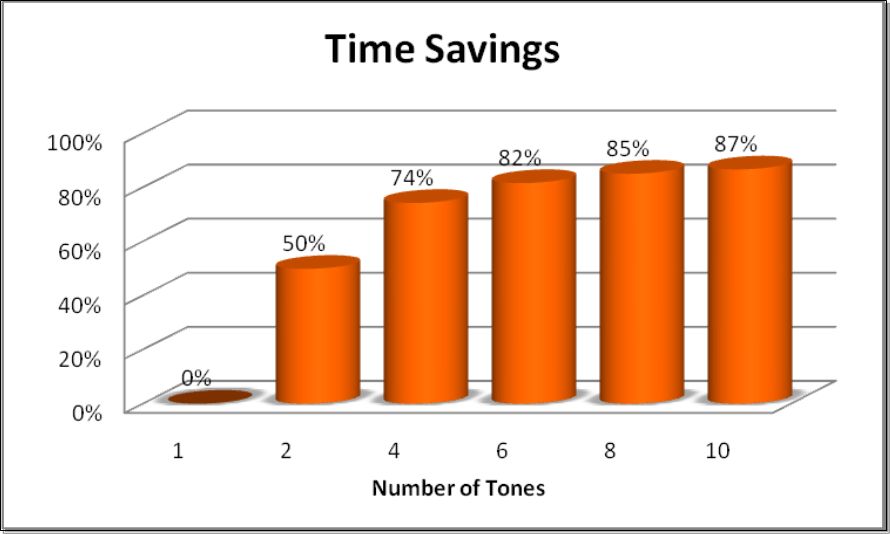

Take heart… a way has been found. The title of this article provides a hint as to how this can be accomplished. AR RF/Microwave Instrumentation has developed a product which uses a patented test process that adds additional test frequencies, or tones, for each test period, or dwell time. Rather than testing one tone per dwell period, we add additional tones to effectively increase the test efficiency by a factor approximately equal to the number of tones used. For example, if four tones were used, the test would be completed in about one quarter of the normal time or four times faster.

Multi-Tone Concept

Since the concept of using multi-tones is so obvious, one wonders why it hasn’t been used before. While simple in concept, the actual hardware implementation has always been a hurdle. Multiple signal sources simultaneously controlled and properly combined in a repeatable fashion has been beyond the scope of readily available test instrumentation. Fortunately, a recent breakthrough in signal generators has provided instruments that meet the stringent requirements of multi-tone testing. While the good news is that the signal generation dilemma has been solved, there are other considerations one must deal with when configuring a multi-tone test. For example, how is the power amplifier affected by the introduction of multi-tones? Does this method comply with the requirements of the test standard? In our attempt to reduce test time, do we comprise the results in any fashion?

As for the effect on the system power amplifier, it has been determined that power requirements are additive. Therefore, a two tone test requires a power amplifier twice as large as the one specified for a standard one tone test. Accordingly, a test consisting of five tones would necessitate a power amplifier five times the base size. The introduction of inter-modulation products resulting from two or more tones will also call for additional power. This effect can be minimized by using a Class A power amplifier within its linear region. Given the complexity of combining more than one test signal while adhering to stringent signal integrity requirements, sophisticated control test software has been developed. This proprietary software uses complex algorithms to measure and find the maximum number of tones possible while staying within the constraints of a valid multi-tone test.

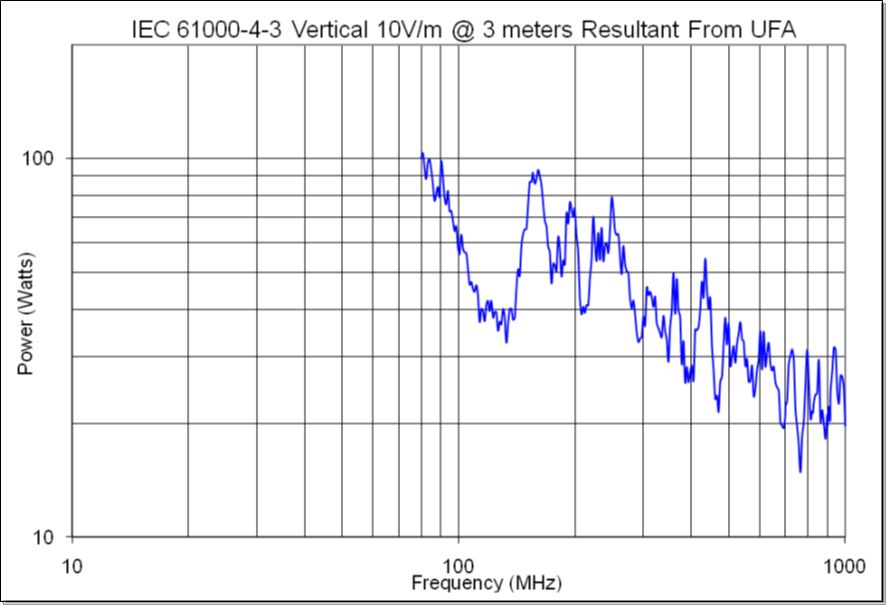

Determination of Required Amplifier Power

One of the limitations of multi-tone testing is the maximum available amplifier power. One tried and true approach in determining amplifier power is to determine the minimum amount of power needed to generate the required test field per the IEC 61000-4-3 radiated immunity test and double it to account for system losses. Since required power varies as a function of frequency, the only way to reliably determine the necessary power is to perform the standard IEC 61000-4-3 uniform field calibration. Figure 2 is a typical plot of the requisite power as a function of frequency. Note that required power falls off rapidly with frequency. Here multi-tone testing could take advantage of the full (formerly unused) power of the amplifier and reduces overall test time. In this specific case a 250 watt amplifier would provide a 2x speedup at the lower frequencies with a much greater reduction in test time at the higher frequencies. In many cases test labs have the power to produce high fields but are testing at lower levels most of the time. With multi-tone testing, test labs could make better use of their unused amplifier power while reducing test times. The argument for adding higher power amplifiers to the test lab has become a little easier since not only will the addition allow for testing at higher field levels, but now the additional power can result is a reduction in test time.

IEC 61000-4-3 Radiated Immunity 80 MHz – 6 GHz Calibration

This test standard very clearly explains the calibration and testing procedure which must be followed to demonstrate compliance. The lengthy 16 point calibration process uses isotropic field probes which are not frequency selective and cannot parse out and measure multiple tones. Therefore, the calibration time cannot be improved using a multi-tone process. The same procedure conducted for the yearly uniform field area calibration is still followed and the results are then evaluated to determine the suitability and extant for multi-tone testing.

Linearity and harmonic content measurements are required as part of the calibration process. When a multi-tone test is planned, it should be understood that all tones must undergo these measurements as well as additional tests. The extra checks use the same criteria noted in the IEC specification for linearity and harmonics and are required in order to define the maximum number of tones that can be used at any given point in the test. At this point, the multi-tone grouping is established for the multi-tone test process.

Testing

Once a determination of how many tones can be used and at what points in the test, testing can proceed at record speed. For each dwell time a set of tones is presented to the EUT. If there is no EUT fault, the test continues. If a fault occurs, the user has the option to immediately investigate with a single tone to verify if the failure also exists when only a single test frequency is used, or continue with the multi-tone test noting where failures occurred. In the second case, after test completion, the failed frequency ranges would be rescanned with a single tone to see if the fault is unique to multi-tone testing or remains even when testing with a single frequency. Additional investigation and threshholding can also be performed at this time. If the EUT demonstrates sensitivity to multi-tones but not with a single tone, the EUT is considered compliant with the test standard. The only downside is that at least at these particular frequencies, one can not reduce the test time. Nevertheless since large sections of frequency ranges can be scanned and tested quickly, overall test time is still reduced.

While the individual tones used in multi-tone testing do not overstress the EUT, the additional energy obtained from combining two or more signals may induce a response in the EUT that is outside the scope of the test standard. If this occurs, the fast testing approach must be suspended in favor of the conventional single tone test. If the EUT continues to fail when subjected to just one test frequency, then testing has indeed uncovered a weakness that must be resolved. Keep in mind that the rational for multi-tone testing is saving time. In the final analysis, the IEC 61000-4-3 standard only requires that the EUT be subjected to one test frequency at a time. Therefore the methodology should be to operate with multi-tones where possible to save time but to step back to single tones when a fault occurs. The graphical representation in Figure 3 captures this testing concept visually. Note that the test proceeds quickly from the lowest frequency up to a point where a fault is encountered. At this point multi-tone testing is suspended and the test reverts to single tone conventional testing. In this hypothetical scenario, it is seen that the EUT passes the single tone testing and multi-tone testing is resumed without further failures throughout the remaining frequency range.

Compliance

The EMC standard is always adhered to with the AR RF/Microwave Instrumentation implementation of multi-tone testing. The major difference between conventional testing and our approach to multi-tone testing is that testing is much faster. For calibration we follow the same procedure outlined in the standard and can level on either forward power or field level without variation. The 2 dB allowable compression margin is checked and used as a criterion for finding how many tones can be used. The harmonic requirement of -6dBc (dB from carrier) in the field is used as a second check on the maximum number of tones used. Once the tone sets are found, they are then used for all multi-tone testing. While the number of allowable tones is determined automatically, the user has the ability to override the software and reconfigure the maximum number of tones in each tone set.

Each and every tone during the test:

-

will be at the correct amplitude to produce the needed field

-

will be at the required frequency

-

will be at the required frequency % step, or in this case % spacing

-

will carry the required modulation of 1 kHz, 80%AM

-

will dwell at the required dwell time for each frequency/tone

It can be seen that all the requirements of the EMC standard are met. The ability to test and demonstrate compliance while significantly reducing test time is now a reality and we are pleased to announce that “the dream has come true”.

Future

One of the future applications of this technology would be to mimic real world threats which are multi-tone in nature. Real world applications expose EUTs to more than one tone at a time. Conventional one tone testing would never uncover susceptibility to these “actual” threats. Some equipment manufacturers have already experienced multi-tone induced EMC failures and have been using multi-tone testing to identify and correct product vulnerabilities. The AR multi star (MT06000 Multi-Tone) test system could make such a task easier to setup and test with the built in algorithms to verify and make sure the signal is not effected by anomalies from inter-modulation products caused by non-linearity.

Jason Smith has been the applications engineering manager at AR since 2004. Previous work experience includes test engineer and EMC lab manager at Radiation Systems and EMC lab manager at Analalb, LLC. Jason has over 10 years experience in EMC testing experience with military, avionics, commercial, medical, telecom and automotive applications. He is a member of the USNC to SC77B and SC77C and a participating member of WG10 (IEC 61000-4-3, -6). He graduated from the University of Delaware in 1997 with a B.S. in Engineering Technology. He can be reached at jsmith@ar-worldwide.com

Pat Malloy has been the sales application engineer at Amplifier Research, now AR, since 1987. Previous work experience includes four years with the U.S. Navy as a guided-missile electronic technician, seven years in an engineering group at AT&T Bell Laboratories, and 16 years as a senior sales engineer for Tektronix. He graduated from Lafayette College in 1972 with a B.S.E.E. He can be reached at pmalloy@ar-worldwide.com