Defense contractors intending to supply military off-the-shelf (MOTS) and/or commercial off-the-shelf (COTS) electrical/electronic equipment for use on UK military platforms, or to integrate them into UK military systems now have new guidance on a risk assessment process for achieving electromagnetic compatibility (EMC). Pete Dorey, senior EMC consultant at TUV Product Services and one of the lead authors of the UK Ministry of Defence Standard 59-411 for Electromagnetic Compatibility, explains the guidance contained in Part 1 of the standard.

One of the difficulties with integrating MOTS and COTS products into complex military systems is achieving electromagnetic compatibility (EMC).

Electromagnetic compatibility is the ability of electrical and electronic equipment and systems to share the electromagnetic spectrum and to perform their desired functions without unacceptable degradation from or to the electromagnetic environment.

Part 1 of the EMC Defense Standard (Def Stan) 59-411, which superseded Def Stan 59-41, focuses on ‘Management and Planning.’Parts 2 to 5 relate respectively to: The Electric, Magnetic and Electromagnetic Environment; Test Methods & Limits for Equipment & Sub Systems; Platform & System Tests & Trials; and Code of Practice for Tri-service Design & Installation.

The MOTS acronym is used to describe both military off-the-shelf or modified off the shelf equipment. Military-off-the-shelf equipment is qualified to a non-UK military EMC standard such as the US standard MIL-STD-461. Modified-off-the-shelf equipment is a COTS product that has been modified to enhance its EMC performance.

Commercial off-the-shelf (COTS) products are proprietary and meet the EMC performance requirements of the EU Directive for EMC, 2004/108/EC, and carry CE Marking that allows their free trade across EU member states.

The incorporation of MOTS and COTS equipment into defense systems and platforms often requires electromagnetic barriers–such as shielded racks and filters and the use of fiber-optics. These measures reduce susceptibility to harsh defense electromagnetic environments and also enhance compatibility with sensitive co-located systems such as military radio. To assess the degree of protection required (or indeed if any is required), the risk assessment process of Def Stan 59-411 can be used to compare the existing EMC compliance of the MOTS/COTS equipment to the defense EMC requirement.

DEF STAN 59-411 EMC RISK ASSESSMENT

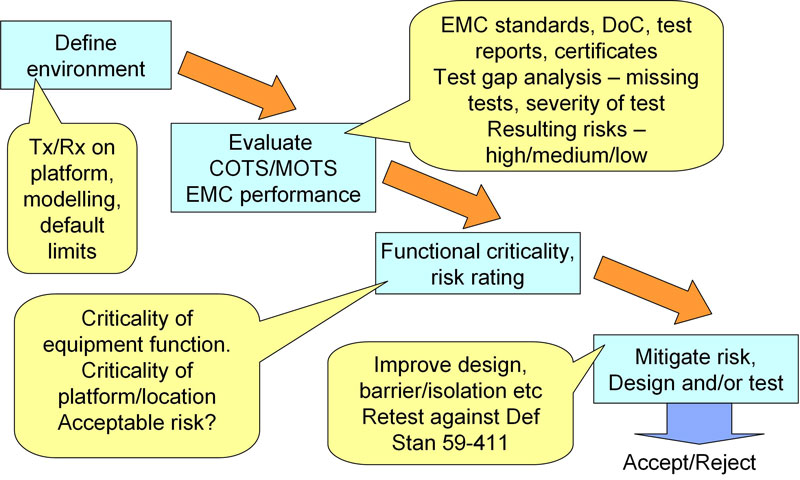

The UK EMC standard for defense procurement, Def Stan 59-411, includes a risk assessment approach in its Part 1 ‘Management and Planning’ for MOTS/COTS equipment as shown in Figure 1. The process requires the intended electromagnetic environment to be defined, the evidence of EMC compliance to be evaluated, and the functional criticality of the equipment and platform to be determined. Finally, the unacceptable risks are to be mitigated by either carrying out remedial re-design, installation methods (electromagnetic barriers), and/or retesting.

SPECIFYING THE ELECTROMAGNETIC ENVIRONMENT

The target electromagnetic environment is usually specified in the User Requirement Document (URD) or System Requirement Document (SRD). It may be specified for a unique purpose, or it may be one of the generic electromagnetic environments encompassed by the default test requirements of Def Stan 59-411 (e.g., a ship below decks environment). Once the environment definition is known, the adequacy of the MOTS/COTS EMC performance can be evaluated.

EVALUATING MOTS/COTS EMC PERFORMANCE

Obtaining the evidence of EMC compliance is one of the major challenges of the risk assessment process. All MOTS/COTS items of equipment must carry CE Marking, which currently may indicate that the manufacturer or supplier declared conformity with either the earlier EU EMC Directive 89/336/EEC for apparatus placed on the market up until 20 July 2007, or has declared conformity with the current EU EMC Directive 2004/108/EC for apparatus placed on the market since 20 July 2007.

In both cases, the requirement for CE Marking does not apply if the apparatus is military equipment exempted under Article 296 of the Treaty of the European Community (as described below under the heading CE Marking Considerations).

For equipment already placed on the market prior to 20 July 2007, the existing declaration of compliance with 89/336/EEC remains valid for a two-year transition period until 20 July 2009. After this date, all equipment must comply with 2004/108/EC.

The manufacturer or supplier prepares a Declaration of Conformity (DoC) identifying the EMC standards to which the equipment is compliant. The DoC may be with the equipment documentation, on the manufacturer’s website, or supplied on request.

Under the current EMC Directive 2004/108/EC, the manufacturer or supplier must maintain ‘Technical Documentation’ containing an EMC assessment such as a Test Report and design information. Ideally, a copy of the EMC Test Report or Test Certificate should be obtained to confirm the actual tests undertaken and the limits applied.

Having identified the EMC standards applied to the MOTS/COTS equipment, a ‘gap analysis’ is performed to evaluate the EMC compliance evidence of the MOTS/COTS equipment against the EMC test requirements of Def Stan 59-411.

To compare test compliance evidence for MOTS/COTS equipment against UK Defense Standard 59-411, differences in the test methods and limits must be identified and accounted for in the comparison. These include ports tested, frequency range, limit levels, emission test detector type, test bandwidth, test distance, susceptibility test modulation, and coupling method. Because of the multitude of commercial standards used today, there is the possibility of numerous comparisons, and consequently gap analysis tools have been developed to assist in this process.

The gap analysis determines whether the MOTS/COTS standard test is more or less stringent than the Def Stan 59-411 test limit and the applicable margin. It also identifies the frequency range addressed by the commercial standard to allow a user to identify untested frequency bands. Based on this information, a user can determine the risk of deploying a piece of equipment meeting the MOTS/COTS standard in an environment represented by the Def Stan 59-411 standard or can identify the degree of additional protection required to meet the Def Stan 59-411 standard in terms of barrier performance, shielding attenuation, and filter attenuation.

FUNCTIONAL CRITICALITY

The risks identified from the evaluation of the MOTS/COTS EMC compliance evidence in the previous process must now be compared to the criticality of the MOTS/COTS equipment and the criticality of the environment or platform in which the MOTS/COTS equipment will be operated. Generally, the greater the criticality of the MOTS/COTS equipment, the lesser the degree of susceptibility risk will be permitted. The greater the criticality of the environment or platform, the lesser the degree of emissions risk will be permitted. Once the project has determined the unacceptable risks, they are mitigated as follows.

MITIGATION OF UNACCEPTABLE RISK

There are two options:

- Retest the MOTS/COTS equipment to determine compliance with Def Stan 59-411. This is technically a good approach as any subsequent required protection can be properly specified, and over-protection will be avoided. However, the disadvantage of this approach is the cost implications of the additional testing required.

- Remedial re-design can be achieved by adding the appropriate protection ‘barriers’ to reduce the coupled RF fields or currents the equipment could be exposed to or could emit to below the levels it was originally required to meet. Many manufacturers now offer suitable RF shielded racks and enclosures for this purpose. These allow the MOTS/COTS equipment to be housed without modification such that line replacement is readily achieved. The gap analysis process provides the barrier performance specification required. Where a piece of modified MOTS/COTS equipment becomes “modified-off-the-shelf” equipment marketed as a variant or new model, the resulting equipment needs to meet the EMC Directive with CE marking as a ‘new apparatus’ in its own right.

CE MARKING CONSIDERATIONS

The manufacturer or supplier of military equipment–whether bespoke, MOTS or COTS–needs to comply with those applicable UK regulations that implement EU Directives including the EU EMC Directive.

The current UK EMC regulations (SI 2006 No. 3418) implementing EMC Directive 2004/108/EC do not have a specific exemption for military equipment; whereas, the previous regulations did include such an exemption (SI 2005 No. 281). Also, the European Commission is re-examining Article 296 of the Treaty of the European Community (TEC)–the so-called ‘military exemption.’ The expected outcome is that defense procurement contracts will require compliance with all applicable EU directives, unless a specific exemption is granted under Article 296 TEC on a case-by-case basis, because of essential national security interests. The existing perception by manufacturers was that a ‘blanket’ exemption applied to military equipment. This assumption is incorrect, and manufacturers need to re-examine their contracts and to apply CE Marking unless specifically exempted.

Applying the EMC Directives to defense projects could lead to the duplication of compliance-testing–once for Def Stan 59-411 and once for CE Marking–and could incur additional costs as well.

However, testing can be minimised by establishing within the Technical Documentation the equivalence between Def Stan 59-411 and commercial standards using the gap analysis process described above. Note that the process can be used in either direction; to show equivalence of commercial standards to Def Stan 59-411 or to show equivalence of Def Stan 59-411 to commercial standards. Note, however, that the generally held perception that Def Stan 59-411 satisfies the majority of the EMC Directive requirements is not always true. Unsatisfied requirements need to be addressed by testing in accordance with commercial standards.

CONCLUSION

Once the Technical Documentation is established, demonstrating compliance with the EMC Directive and the associated commercial standards, the manufacturer or supplier then makes a Declaration of Conformity and applies CE Marking. What assistance is available in this process? Third-party certification of the technical documentation is no longer mandatory, and the current EMC Directive has replaced ‘Competent Bodies’ with ‘Notified Bodies’ whose involvement in assessing the Technical Documentation is optional. However, given the complexity of performing gap analysis, a Notified Body provides a low risk solution.

Pete Dorey is a Senior EMC Consultant at TÜV SÜD Product Service. He can be reached at Peter.Dorey@tuv-sud.co.uk