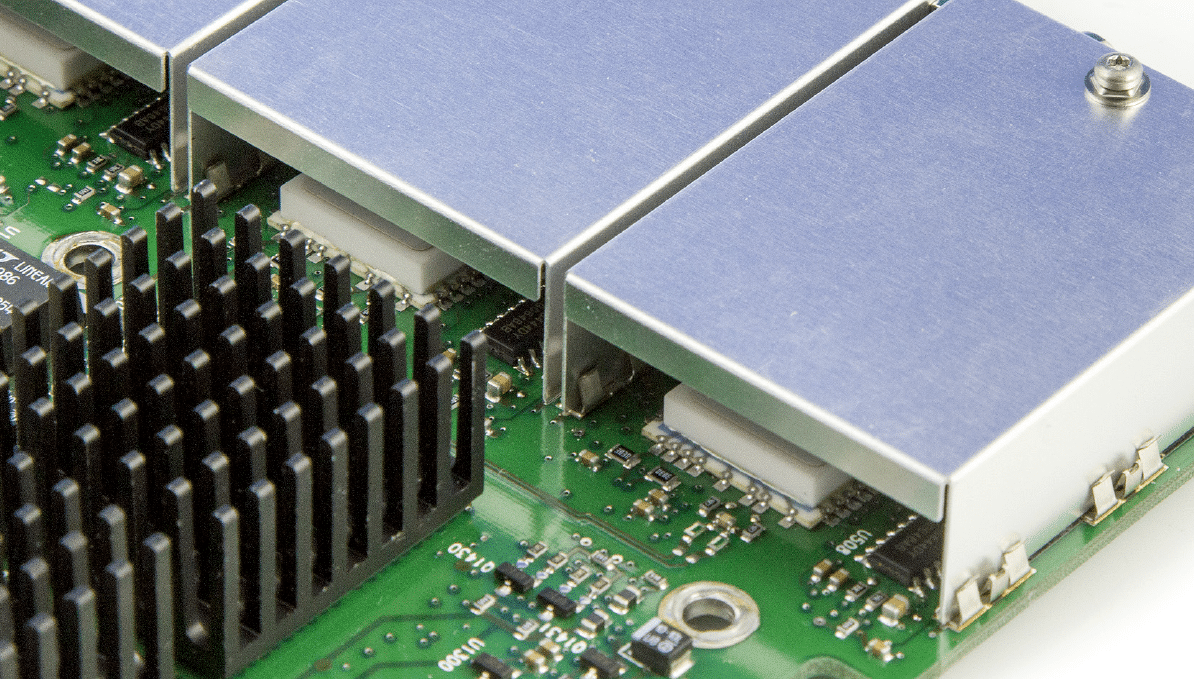

The Purpose of Board Level Shields

Board level shields (BLS) are generally small metallic shielded boxes mounted directly to PC board ground return layers. There are three primary purposes of board level shields:

- Isolation of sensitive circuitry from other noisy circuits on the board

- Trapping the emissions from noisy circuits on a board from propagating to the outside environment

- Keeping RF sources from the external environment from disrupting sensitive circuitry on the board.

Note that, depending on the wavelengths of the RF sources or noise, the connecting pin spacing for the attachment to ground return layer may need to be fairly close together. A good rule of thumb is no farther apart than 1/20th of a wavelength at the highest expected frequency.

For critical applications, some board level shields are soldered with a continuous seam along the attachment point to the PC board.

Selecting a Shielding Manufacturer

The first step in specifying board level shielding is selecting a shielding manufacturer who can design and produce both standard and custom BLS while offering design flexibility for surface-mount and through-hole configurations.

Ideally, this manufacturer will offer an array of standard shields that can be customized to any performance or application requirement, meeting today’s challenging EMI/RFI shielding applications.

An extensive selection of standard BLS features (pin options, corner options, etc.) and material/design options will make it easy for you to specify board level shields that meet your product requirements.

Look for the following:

- Unlimited shield sizes

- Variety of material options

- Multiple fence/cover retention methods

- Variety of pin and surface-mount styles

- Custom trace notches at no extra cost

- Standard ventilation holes

- Part number and logo identification

- Standard pick target for pick and place

- Tape-and-reel and/or tray packaging

- RoHS compliance

Choosing Your Features & Performance Specs

Whether you’re in need of one-piece, two-piece, multi-cavity, or custom-configured shielding, your next step is choosing the features and performance specs that will transform your shielding concept into a high-performance reality:

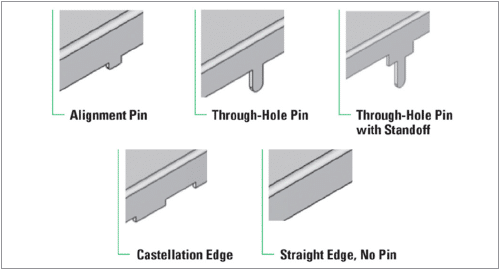

Pin Options

- Alignment Pins

- Through-Hole Pins

- Through-Hole Pins with Standoffs

- Castellation Edges

- Straight Edges with No Pins

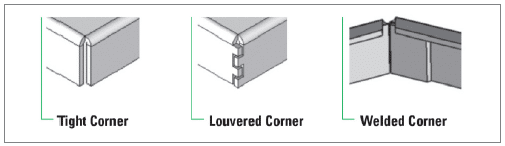

Corner Options

- Tight Corners

- Louvered Corners

- Welded Corners

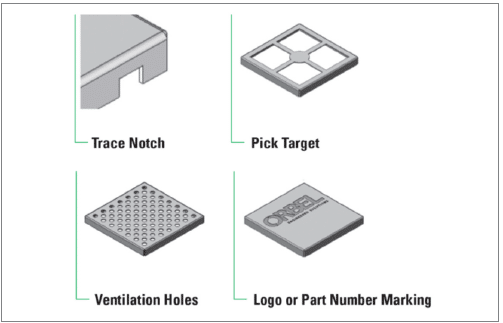

Additional Options

- Trace Notches

- Pick Targets

- Ventilation Holes

- Logo or Part Number Markings

When choosing performance specs, it is also important to consider your material options (nickel silver, beryllium copper, phosphorus bronze, stainless steel, etc.), co-planarity, material thickness, RoHS compliance, and shielding effectiveness.

Configuring & Ordering Your Shielding

Most BLS manufacturers utilize a part number system that both serves as a product reference guide and identifies the way a shield has been configured.

In the case of Orbel Corporation, the part number codes are as follows and are described in the example shown.

For example, let’s evaluate a sample Orbel part number, B-0750 TB 1125-0250 X F-TPS, piece by piece. Other manufacturers may have a similar part numbering system.

“B” represents the “B” in “Snap-Shield Bullzeye™,” a popular board shield style. Other board shield styles include:

G = EZ-Shield Guardian™

M = Snap-Shield Micro™

L = Snap-Shield LaZerLock™

S = Snap-Shield SmartFORM™

T = Snap-Shield TRU-View™

V = Vault-Shield™

H = Snap=Shield HEMI™

“0750” represents the shield’s frame width.

“TB” represents “Through-Hole (0.500” spacing),” the shield’s mounting style. Other standard mounting styles include:

TA = Through-Hole (0.250” spacing)

TC = Through-Hole (1.000” spacing)

SA = Surface-Mount with Alignment Pins

SB = Surface-Mount with Castellations

SC = Surface-Mount with No Pins

“1125” represents the shield’s frame length.

“0250” represents the shield’s frame height.

“X” represents a material thickness of 0.010”, which is a standard size for Orbel. Other standard material thicknesses include:

Y = 0.015”

Z = 0.008”

“F” is the shield code for “Shield Frame.” Other standard shield codes include:

C = Shield Cover

A = Assembled

P = Unassembled Pair

“TPS” represents “Tin-Plated Steel.” Other standard material options include:

No Code = Nickel Silver (standard)

TPB = Tin-Plated Brass

TPC = Tin-Plated Copper

Other manufacturers will offer similar coding.

Specifying Custom Board Level Shielding

If you are in need of a custom BLS solution, make sure you are working with a shielding manufacturer with proven engineering expertise and the advanced production techniques needed to deliver unlimited design flexibility.

If your manufacturer offers custom features for both surface-mount and through-hole shield configurations, they will be able to transform your shield concept into an innovative, cost-effective solution.

Look for the following custom capabilities:

- One-piece, two-piece, and multi-cavity

- Unlimited design flexibility

- Any shape or size

- Wide selection of materials

- Variety of plating finishes

- Consultative engineering services

With the right shielding manufacturer on your side, any shielding concept can be turned into a practical BLS solution. Simply convey the features you need to incorporate into your shield design, and your manufacturer can help you create a custom-configured shield that meets your needs.

Please Feel Free to Contact the Author for Any Questions at: kmarino@orbel.com.