Dario Negrini

Leader Tech Inc.

Tampa, FL

Let’s face it. If you didn’t have to worry about EMI shielding issues with your circuit board, life would be much simpler. Unfortunately, as product designs continue to shrink in size and as the list of features continues to grow, EMI compliance issues cannot be overlooked. Circuit board shields are one of the best ways to resolve these design challenges. They allow designers to resolve most EMI issues at the board level while avoiding the greater costs often involved with using metallized coatings or gaskets.

Initial Design

The main thing to remember when designing circuit board shields is that they should be part of the initial board layout and not an afterthought. By including shields in the initial board design, the successful design engineer can leverage features of these shields to achieve shielding with minimal expense. Standard features in shield designs should not be confused with commonplace off-the-shelf EMI shields. Such off-the-shelf shields do not offer any design flexibility. They either work in an application, or they don’t. The availability of standard features such as pin spacing, cover retention, and ventilation allows the designer to take advantage of low costs (usually with no Non-Recurring Engineering (NRE) charges) and to create a custom solution for a given EMC application.

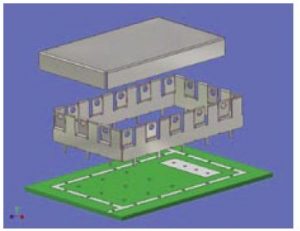

Take the example of a circuit board with an area approximately 1.2˝ x 2.45˝ to be shielded with a height requirement of 0.5˝ and the need for a removable cover. A designer should first determine if those dimensions match some of the standard features of circuit board shield designs. There are several standard fence designs that can achieve a footprint that is very similar to these requirements. The example shown in Figure 1 achieves a footprint that is 1.262˝ x 2.562˝ center-to-center. This solution uses a fence design that is based on a ¼˝ pitch and is formed to the desired dimensions. By using this footprint, the product can be ordered with a one-week lead-time without any NREs. If the changes are not feasible, there are other options ranging from a modification to a standard product to ordering a custom fence that still incorporates some standardized features such as cover retention.

Design Considerations

The following is a list of some of the design considerations that should be reviewed during the board design.

One Piece or Two?

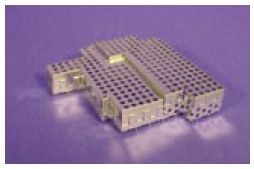

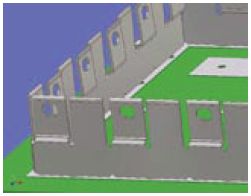

A surface mounted, one-piece shield, without any locating pins, is by far the most cost-effective method of circuit board level shielding. If components must be accessible after shielding, or if the shield is to be reflowed, a two-piece design is the solution. In two-piece designs, the designer can choose between a one-piece frame and a fence that is formed to the needs of the application. The fence design offers several advantages, including the significant benefit of flexibility. Figure 2 shows a standard fence material that has been formed into a complex L shape. Achieving this design with a one-piece frame would require either tooling or photo etching—both techniques that require some form of NRE and that could not be changed easily if the need should arise. If a standard fence design does not meet the dimensional needs of the application, a custom fence can be the solution. Such a fence can incorporate standard features such as an interlocking corner (Figure 3), welded corner tab, pin spacing (1/2˝, 1˝, etc), or dimple slots. The incorporation of these standard features allows for a cost-effective custom solution.

Cover Retention

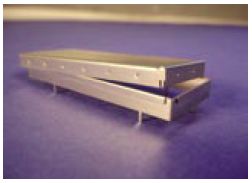

If a two-piece shield is needed, cover retention becomes an important factor. Does the application have to withstand vibration/shock testing? If so, the design must be based on products that will assure survivability (Figure 4). If the application necessitates a more customized design, a standard feature such as strong cover retention that can be incorporated into a custom fence (Figure 5).

Many applications require modifications to either the fence or the cover for traces, components, tuning, etc. All of these modifications can be achieved cost-effectively if dealing with a supplier that has a large universal tooling base that can accommodate these modifications. Traces on the board can be handled easily by either choosing a fence with stand-offs or by putting a small mouse-hole at the bottom of the fence. Tuning holes can be designed using different diameters. Accommodating a connector on the side of a fence can be handled either by placing a notch in the fence (Figure 6) or (depending on the height requirement) by starting and ending the fence on either side of the connectors and sizing the cover to meet the height requirement.

Affixing the Shield

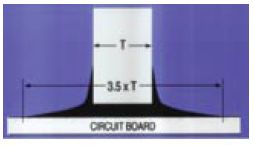

A common area of confusion involves affixing the shield to the board. Quite often, designers regard circuit board shields as being either through-hole or surface mount. The reality is that a combination of both provides an optimal solution. One of the most successful designs involves a solder trace under the edge of the shield as well as some pattern of holes. The solder trace can provide an excellent soldering surface when mated to a fence design that meets the board in a knife-edge method (Figure 7). During assembly, the edge of the fence cuts easily through the surface tension of the solder paste. When using other designs, the surface tension of the solder paste can present a “floating” effect. At the reflow stage, the solder wicks very effectively up the sides of the shield and assures an excellent EMI seal. The pins are very effective at locating and maintaining the shield in place during assembly and reflow. Additionally, the pins allow the designer to create a ground path through the layers where necessary.

Ventilation

Heat is another common problem in board designs. Ventilation holes on the covers or fences of circuit board shields can be an effective way to get rid of some that heat. It is best to design around the standard hole sizes that might be available. Custom hole patterns are always available, but they will increase costs and lead-times.

Conclusion

Circuit board shielding can be one of the most cost-effective solutions to EMI challenges. Taking the time to find a provider offering the standard designs for a particular application is worth the effort. Ideally, the supplier should provide the service and design support that allows the designer to concentrate PCB functionality. A “collaborator” with proven shield solutions can be an invaluable ally in solving the challenges of any application.

Dario Negrini is the president of Leader Tech, Inc., a HEICO company, located in Tampa, FL., that specializes in both standard and custom EMI solutions. He is a 20-year veteran of the EMI shielding industry. Prior to his joining Leader Tech, he held a VP of Sales & Marketing position with one of the largest global EMI shielding manufacturing companies. His 20 years of experience in the shielding industry coupled with his knowledge of the electronics industry are key factors in customer applications, large and small. Dario has published numerous articles dealing with EMI specific applications and a variety of Tech-Notes that confront multiple application situations. Dario can be reached at sales@leadertechinc.com.