Introduction

This article describes how I perform pre-compliance testing for the top four EMI issues I constantly run into; conducted emissions, radiated emissions, radiated immunity, and electrostatic discharge. Of these, the last three are the most prevalent issues, with radiated emissions typically being the biggest compliance challenge during certification testing. If your product or system (EUT) has adequate power and I/O port filtering, conducted emissions and the other power line-related immunity tests are not usually an issue.

You might consider assembling your own EMI troubleshooting kit. For your convenience, I’ve developed a list of recommended equipment useful for troubleshooting EMI. The download link is listed in Reference 1.

Ambient Transmitters

One problem you’ll run into immediately when testing conducted or radiated emissions outside of a shielded room, is the number of ambient signals from sources like FM and TV broadcast transmitters, cellular telephone, and two-way radio. This is especially an issue when using external antennas. I’ll usually run a baseline plot on the analyzer using “Max Hold” mode to build up a composite ambient plot. Then, I’ll activate additional traces for the actual measurements. For example, I often have at least two plots or traces on the screen; the ambient baseline and the actual pre-compliance measurement.

Fortunately, there are three ways around this:

- In most cases, you’ll observe a range of product emissions in a harmonic relationship. Very often, these harmonics are created from the same source and if one, or more, are masked by ambient signals, then working on the others that are more visible will generally bring the whole batch down, as well.

- In some cases there will be a critical harmonic masked by an ambient transmitter. A good example is a 100 MHz harmonic hidden underneath a large FM broadcast station at 99.9 MHz. In this case, I’ll try reducing the resolution bandwidth from 100 or 120 kHz down to as little as 1 kHz, or less. This often “filters out” the modulation from the FM station, allowing you to observe the hidden harmonic. This also presumes the harmonic is an unmodulated continuous wave (CW) signal. Just be sure reducing the RBW doesn’t also reduce the harmonic amplitude. If your harmonic is modulated, this may not work and you may have to move to a quieter measurement site.

- Move your pre-compliance testing well away from urban transmitters (easier said than done these days).

Another caution when using spectrum analyzers is that strong nearby transmitters can affect the amplitude accuracy of the measured signals, as well as create mixing products that appear to be harmonics, but are really combinations of the transmitter frequency and mixer circuit in the analyzer. You may need to use an external bandpass filter at the desired harmonic frequency to reduce the affect of the external transmitter. An example would be an FM broadcast band “stop band” filter.

Although more expensive, an EMI receiver with tuned preselection would be more useful than a normal spectrum analyzer in high RF environments. Suppliers, such as Keysight Technologies or Rohde & Schwarz, make EMI receivers. All these techniques to deal with ambient signals are described more fully in Reference 2.

Conducted Emissions

This is usually not an issue given adequate power line filtering, however, many low-cost power supplies lack good filtering. Some “no name” brands have no filtering at all! The conducted emissions test is easy to run and only requires a line impedance stabilization network, or LISN (basically an impedance match from the power line to 50 Ohms). Figure 1 shows a typical LISN.

I prefer setting the vertical units from the default dBm to dBμV, so the displayed numbers are positive. Then adjust the Reference Level for even increments along the vertical axis. This is also the same unit used in the test limits of the EMI standard. I also like to set the horizontal scale from linear to log (if possible), so frequencies are easier to read out.

Set up your spectrum analyzer as follows:

- Frequency 150 kHz to 30 MHz

- Resolution bandwidth = 9 kHz, per the standard, or 10 kHz is close enough

- Preamp = Off

- Set the vertical units to dBμV

- Adjust the Reference Level so the highest harmonics are displayed and the vertical scale is reading in even 10 dB increments

- Use average detection initially and CISPR detection on any peaks later

- Internal attenuation — start with 20 to 30 dB at first and adjust for best display and no analyzer overload.

Obtain a Line Impedance Stabilization Network (LISN) and position it between the product or system under test and the spectrum analyzer. Note the sequence of connection below!

CAUTION: It’s often important to power up the EUT prior to connecting the LISN to the analyzer. This is because large transients can occur at power-up and may potentially destroy the sensitive input stage of the analyzer. Note that the TekBox LISN has built-in transient protection. Not all do…you’ve been warned!

Ideally, you’ll want to set up the test according to CISPR 11 or 32 (depending on the type product, ISM or ITE). See Figure 2 for an example. The LISN is bonded to the ground plane and the EUT is placed on a table 80 cm high.

Power up the EUT and then connect the 50-Ohm output port of the LISN to the analyzer. Note the harmonics are usually very high at the lower frequencies and taper off towards 30 MHz. Be sure these higher harmonics don’t overdrive the analyzer. Add additional internal attenuation, if required.

By comparing the average detected peaks (or quasi peak, if your analyzer offers this option) with the appropriate FCC or CISPR limits, you’ll be able to tell whether the EUT is passing or failing prior to formal compliance testing. Refer to the References section for FCC and CISPR conducted emission limits in dBμV.

Radiated Emissions

This is normally the highest risk test and most prone to fail compliance testing. Therefore, setting up this test in-house should be a priority. Performing an accurate pre-compliance test for radiated emissions requires a calibrated EMI antenna positioned either 3m or 10m away from the product under test. This way, you’ll be able to compare the emissions with actual test limits. These antennas can range in price from $1,000 to $6,000 USD.

The test should be set up in any area large enough and far away from other equipment that could interfere with the testing. Sometimes a parking lot is used. I’ve more often used a large conference room (Figure 3).

I prefer setting the vertical units from the default dBm to dBμV, so the displayed numbers are positive. Then adjust the Reference Level for even increments of 10 along the vertical axis. This is also the same unit used in the test limits of the EMI standards and also used in the equation below for calculating the E-field level. I also like to set the horizontal scale from linear to log (if possible), so frequencies are easier to read out.

Set up your spectrum analyzer as follows:

- Frequency 10 to 500 MHz

- Resolution bandwidth = 120 kHz, per the standard, or 100 kHz is close enough

- Preamp = On (or use an external 20 dB preamp if the analyzer lacks this). This may not be required if the harmonic emissions are observable without it.

- Set the vertical units to dBμV

- Adjust the Reference Level so the highest harmonics are displayed and the vertical scale is reading in even 10 dB increments

- Use positive peak detection

- Set the internal attenuation = zero

You can calculate the E-field (dBμV/m) at a given measurement distance (typically 3m or 10m) by recording the dBμV reading of the spectrum analyzer and factoring in the coax loss, external preamp gain (if used), any external attenuator (if used), and antenna factor (from the antenna calibration provided by the manufacturer). This calculation can then be compared directly with the 3m or 10m radiated emissions test limits using the formula:

E-field (dBμV/m) = SpecAnalyzer (dBμV) – PreampGain (dB) + CoaxLoss (dB) + AttenuatorLoss (dB) + AntFactor (dB)

Refer to the References section for FCC and CISPR radiated emission limits in dBμV/m.

Radiated Immunity

Most radiated immunity tests are performed from 80 to 1000 MHz (or, in some cases, as high as 2.7 GHz). Common test levels are 3 or 10 V/m. Military or automotive products can go as high as 50 to 200 V/m, depending on the operational environment. The commercial standard for most products is IEC 61000-4-3, whose test setup is quite involved and relatively expensive, in that it requires lots of test equipment and a semi-anechoic chamber designed for a uniform E-field at the EUT position. However, using some simple techniques, you can identify resolve most issues quickly on the work bench.

Handheld Radio — For radiated immunity, we generally start outside the EUT and use license-free handheld transmitters, such as the Family Radio Service (FRS) walkie-talkies (or equivalent) to determine areas of weakness. By holding these low power radios close to the product or system under test, you can often force a failure (Figure 4).

Hold the transmit button down and run the radio antenna all around the EUT. This should include all cables, seams, display ports, etc.

RF Generator — It’s very common that only certain frequency bands are susceptible and sometimes the fixed frequency handheld radios are not effective. In that case, I use an adjustable RF generator with attached large size H-field probe and probe all around at known failing frequencies. It also helps to probe the internal cables and PC board to determine areas of sensitivity. For smaller products, as in Figure 5, try using the smaller H-field probes for best physical resolution.

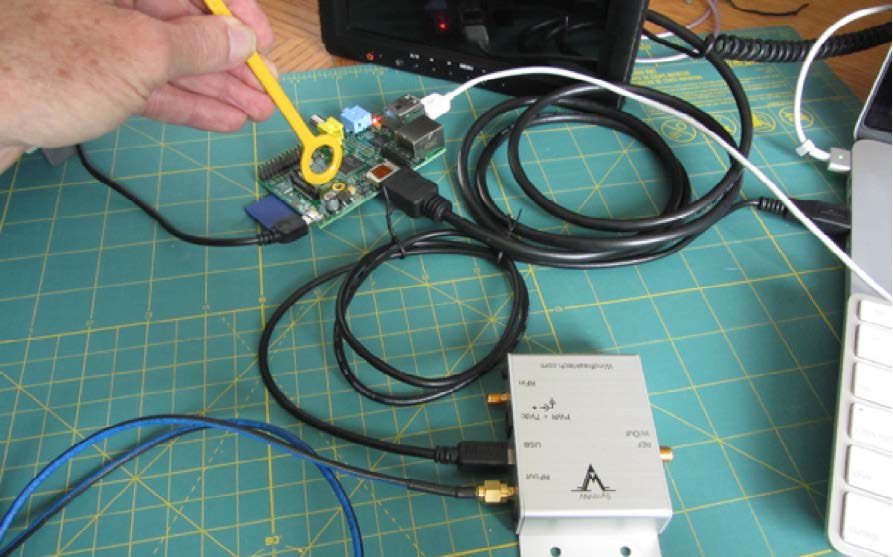

In place of the larger lab-quality RF generators, I also use a smaller USB-controlled RF synthesizer, such as the Windfreak SynthNV (or equivalent) with the near field probe. The SynthNV is USB-controlled and can produce up to +19 dBm RF power from 34 MHz to 4.4 GHz. This also fits into my EMI troubleshooting kit nicely. See Figure 6. You’ll find a list of recommended generators in Reference 1.

Electrostatic Discharge

Electrostatic discharge testing is best performed using a test setup as described in the IEC 61000-4-2 standard. This requires a test table and ground planes of certain dimensions. The EUT is placed in the middle of the test table. I usually suggest replacing floor tiles with copper or aluminum 4 x 8-foot sheets, which will fit right into the spaces of the existing tiles (Figure 7).

Testing requires an ESD simulator, which is available from a number of sources. See Reference 1. I use the older KeyTek MiniZap (Figure 8), which is relatively small and can be adjustable to +/- 15 kV. There are several other suitable (and newer) designs.

ESD testing is rather complex as far as identifying the test points, but basically, there are two tests — air discharge and contact discharge. Use air discharge for all points where an operator could touch the outside of the EUT. Use contact discharge for all exposed metal where an operator could touch and discharge into. Test both positive and negative polarities. Most commercial tests require 4 kV contact discharge and 8 kV air discharge.

The test setup also includes horizontal and vertical coupling planes. Use the contact discharge tip into the coupling planes. These planes need a high-impedance discharge path to earth. See the IEC 61000-4-2 standard for details and exact test procedures.

Summary

By developing your own EMI pre-compliance tests, you’ll save time and money by moving the testing process in-house, rather than scheduling time and the related cost and scheduling delays by depending on commercial test labs.

Most of the high-risk EMI tests are easily performed with low-cost equipment. The cost savings by performing troubleshooting at you own facility can mount up to hundreds of thousands of dollars and weeks or months of product delays.

References

1. Recommended list of EMI troubleshooting equipment – http://www. emc-seminars.com/EMI_Troubleshooting_Equipment_List-Wyatt.pdf

2. André and Wyatt, EMI Troubleshooting Cookbook for Product Designers, SciTech, 2014.