ABSTRACT

Our automobiles are becoming more connected and reliant on wireless connectivity, and at the same time, the number of high-compute internal systems is rapidly increasing. Like any high-speed, complex digital electronic system, automotive electronics can be both a cause of, and highly sensitive to, electromagnetic interference (EMI), and the consequences of failure can be fatal. In this article, we discuss sources of EMI, and steps engineers can take to identify, isolate, and reduce its impact.

Keywords: EMC, EMI, EMS, PXI, automotive test, connected car, test for manufacture, time domain scan, TDS, safety standards, CISPR 16-1-1, radiated emissions, conducted emissions, IEC, ANSI C62.3, radiated immunity

In 1915, a book was published—The Model T Ford Car: Its Construction, Operation, and Repair, by Victor W. Page [1]. It explained the “operating principles of all parts of the automobile” and extended to just 302 pages (with advertisements). How big would the book be to describe the operating principles of a modern car? Just the 100 million+ lines of code in 100+ embedded processors would fill around 10,000 books. The complexity of cars today is extreme with interconnected functional, control, safety, driver assistance, communications, and infotainment electronic systems.

The picture is more complicated when ‘V2X’ interactions are included: Vehicle-to-Vehicle, Vehicle-to-Infrastructure, Vehicle-to-Person, and Vehicle-to-Network. With a semi- or fully-autonomous driving, complexity, and safety concerns multiply up further.

It’s clear that keeping a heavy vehicle loaded with explosive fuel, or high-energy batteries safe at high speed, requires all of the on-board systems to interface correctly with no surprises. While the highest levels of engineering discipline in design can define and control the electrical and mechanical interfaces, electromagnetic effects and compatibility (EMC) are much harder to predict. The consequences of system interference can be dire—there have been reports of airbags spontaneously deploying, triggered by emergency service vehicle RF transmissions and engine management, and cruise control systems demanding ‘full throttle’ when subjected to EMI [2].

Robust designs are therefore necessary to ensure system EMC along with verification by simulation and test to automotive compliance standards.

A COHERENT APPROACH TO TEST THROUGH INTERNATIONAL STANDARDS

While good design practices and use of EMC/EMI simulation tools can minimize an electronic system’s EMI susceptibility and emissions, performance is often affected by the installation conditions and interconnections with other equipment. With components, modules, and sub-systems sourced from multiple tiers of suppliers, individual EMC performance can only be characterized under agreed ‘standard’ conditions, which may not match the intended EMC/EMI environment. Compliance at all component, module, and system levels, though, is a good starting point.

The ultimate goal is to achieve certification of the vehicle to relevant standards, including EMC, with an ‘E’ mark, mandatory in the E.U. and other countries that have signed up to the scheme. The E-mark is applied to components, separate technical units (STU), and electrical sub-assemblies (ESA) as well as the complete vehicle. For most countries, the relevant automotive EMC standard is United Nations regulation ECE R10, currently at revision 5, which also covers EMC requirements for electric (EV) and hybrid-electric vehicles (HEV). For the U.S., the Society of Automotive Engineers (SAE) and automotive OEMs set the standards. These generally reference international standards for EMI limits and test methods, as defined by ISO, IEC, CISPR as well as American ANSI documents. Other countries, such as India and China, have local requirements. Vehicle manufacturers have their internal standards too, often with more stringent specifications, such as Ford CS2009, Chrysler- Fiat CS11979, or Nissan NDS02.

The automotive environment is hostile, with conducted and radiated emissions from high-power switching converters and data lines, as well as transients and dips from load dumps and current surges but new automotive technologies and operating conditions are adding to the burden, and test standards must evolve to match. For example, ECE R10 EMC requirements now differentiate between electric vehicles at charging stations or on the road. Also, the introduction of new RF technologies such as automotive radar systems at 24/77/79 GHz and 5G connectivity, which can also operate between 24 and 86 GHz require verification for compatibility with each other and existing car systems.

Applying the EMC standards and employing certification agencies to achieve E-marking for components and sub-assemblies, with supporting simulation, test documentation, and manufacturing quality control are obligatory—and necessary, as an EMC failure at the vehicle level can be extremely expensive to rectify. THE EMC ENVIRONMENT EMC concerns range across all the systems in automotive applications from traction motor drives in EVs to BluetoothTM connection for infotainment, involving the whole RF spectrum from kHz to GHz (Figure 1).

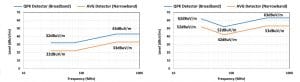

EMI is categorized into four areas, conducted/radiated emissions and conducted/radiated susceptibility, with their specific compliance standards and limits. Conducted emissions can be measured in open lab conditions, but radiated measurements require an open area test site (OATS) or anechoic chamber to eliminate spurious signals. Taking radiated emissions as an example, ECE R10 refers to CISPR 16 for broadband and narrowband emissions between 30 MHz and 1 GHz with limits, shown in Figure 2, for whole vehicles at 10 m (left) and ESAs/ components (right). The measurement resolution bandwidth is 120 kHz.

U.S. specifications might reference ANSI standards ANSI C63.2 and C63.4 for emissions measurement methods and instrumentation respectively, covering the range 9 kHz to 50 GHz.

The key to the measurement of conducted and radiated emissions is an EMI receiver conforming to the CISPR 16 requirements. Specific characteristics needed are a selectable signal detection method and measurement resolution bandwidth (RBW)—the ability of the measurement to separate spectrum components. RBW varies between the standards and can be between 9 kHz and 1 MHz. EMI receivers provide several options for signal detection as defined by CISPR 16: based on the applicable standard, either a ‘peak’, ‘quasi-peak’, or ‘average’ detector is selected, each with different detection time constants to more-or-less attenuates random or non-repetitive components of the measured signal. Quasi-peak, for example, is weighted according to the repetition rate of the signal, and the receiver must dwell at the measured frequency to allow the detector to evaluate this parameter. Peak, however, is an almost instantaneous measurement so dwell time is less and will always show a higher response than quasi-peak or average, so if limit lines are met with peak detection, then all is well. If peak detection fails the limits, there is no choice but to use quasi-peak and average to try to show compliance—a very slow measurement with traditional receiver designs.

NEW RECEIVER TECHNIQUES REDUCE MEASUREMENT TIMES DRAMATICALLY

New receiver techniques, however, can make the quasi-peak and average sweep times much faster. The advantages are improved measurement accuracy, better repeatability, better filter shape factor, and ability to take a Fast Fourier Transform (FFT) of the digital signal, which, in turn, allows a ‘Time Domain Scan’ (TDS). This technique can speed up quasi-peak and average detection sweeps dramatically by dwelling only once at the bandwidth of the FFT operation. This encompasses hundreds if not thousands of RBW values and speed is enhanced further by a reduction in the number of total scans, requiring fewer local oscillator steps and associated re-lock delays.

CONCLUSION

Evaluating EMC between a huge range of disparate systems in automotive applications is a daunting task. The stakes are high for OEM time-to-market, and user safety is a higher priority still. Using a PXE series of EMI receivers guarantees the best measurement accuracy at the fastest speeds backed up by a test and consulting service that supports users all the way from initial design to full regulatory compliance testing.

REFERENCES

- https://archive.org/details/modeltfordcarits00pagrich/page/n1

- Radiocommunications Agency EMC awareness: https://www.emcia.org/emc-awareness