In my first article, I gave an overview of RTCA’s DO-160 and the electrical EMC sections that it entails. In the next few articles I will be discussing the most critical EMC section of DO-160.

Critical sections DO-160

Sect 16.0 – Power Input

Sect 20.0 – Radio Frequency Susceptibility (Radiated and Conducted)

Sect 21.0 – Emission of Radio Frequency Energy

Sect 22.0 – Lightning Induced Transient Susceptibility (Pin Injection and Cable Bundle)

These four sections make up the most critical sections of DO-160 because of their complexity and, as a result, the risk of failure. In this post we will examine lightning induced transient susceptibility or indirect lightning as the design constraints around indirect lightning have a significant impact on other sections such as power input.

Indirect Lightning

As mentioned in my previous overview post, indirect lightning simulates the coupling of energy onto a unit’s interconnecting cables in the event of a lightning strike. DO-160 is broken down into three sections; pin injection, single/multiple stroke, and multiple burst.

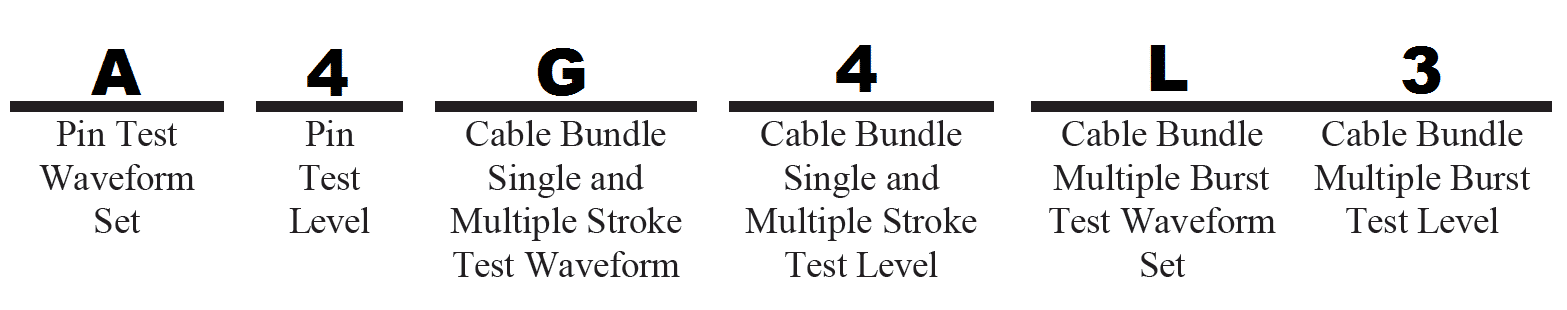

While single/multiple stroke and multiple burst represent a real-life occurrence where energy is coupled on to a cable bundle routed along aircraft, pin injection is less rooted in a realistic scenario but provides a simple and foolproof way to test the robustness of one’s product. A requirement from an aircraft manufacturer will look like Figure 1, in DO–160 revision G.

Figure 1: DO-160 Section 22.0 Category Explanation

In this example from DO-160 revision G, A4 represents the pin injection requirement, G4 represents the cable bundle single and multiple stroke requirement and L3 represents the multiple burst requirement. However previous revisions of DO-160 combine the letter designation for cable bundle and multiple burst.

Pin Injection

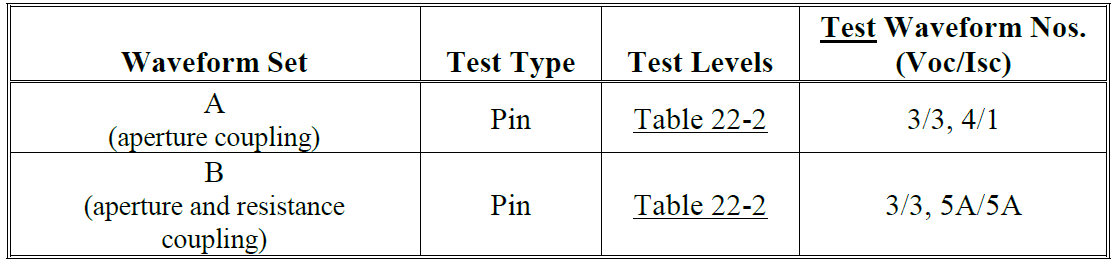

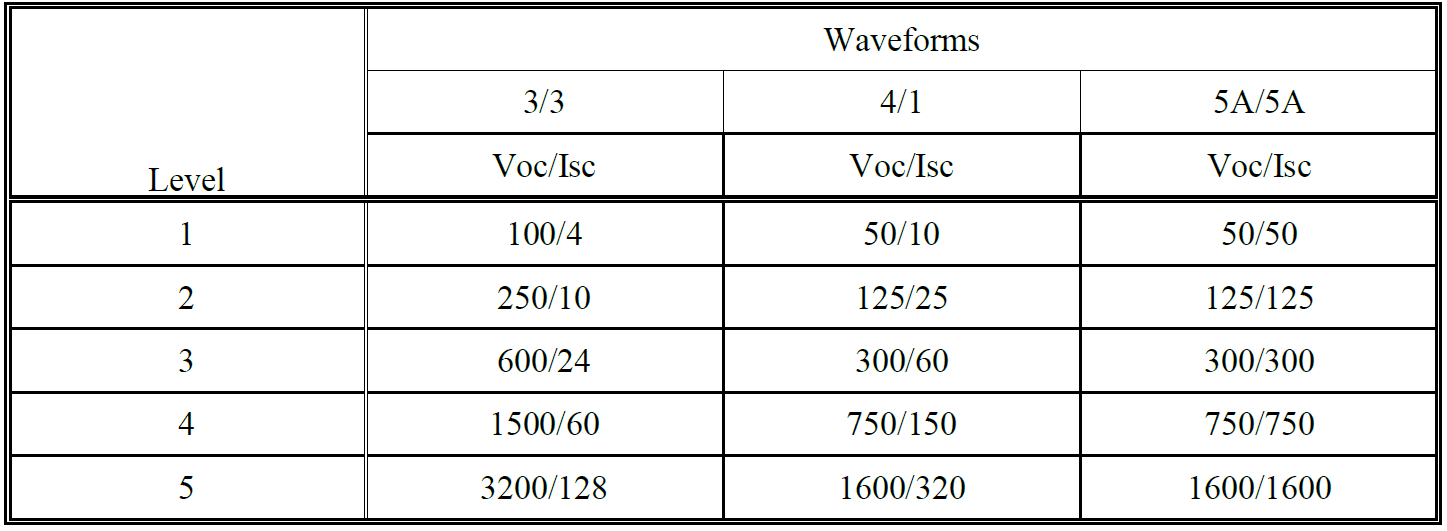

Testing pin injection to A4 means that category A will require you to test against waveform 3 and waveform 4 at pin injection level 4. An example is shown in Figure 2 and Figure 3.

Figure 2: DO-160 Table 22-1.1 Pin Injection Waveform Set

Figure 3: DO-160 Table 22-2 Pin Injection Levels

Pin injection uses a fixed energy level, calibrated before the test and applies it to each pin of your unit. The VOC represents an open circuit voltage and the ISC represents a short circuit current. The waveform generator’s amplitude is increased until an open circuit voltage at the required level is achieved. Using that same generator amplitude in a short circuit condition, the calibration should achieve the short circuit current requirement level. Once both these are achieved the calibration amplitude is recorded.

The lightning generator test point is then applied to each pin of your unit and the amplitude is set to the predetermined level during the calibration. The calibrated level is applied to each pin of your unit in both the positive and negative polarity, ten times each. Typically, this test is a damage tolerance test and as such your unit is not required to operate through. Often, if the device is simple, the aircraft manufacturer or certification authority may allow your unit to be unpowered during the test. This allows for a simple set up and very little test support equipment.

Though pin injection category A4 shows waveform 3 at 1500 V and 60 A, when applying this energy to each pin, you should not expect to see either of these levels. Remember that during calibration 1500 V was only achieved because the circuit was high impedance. 60 A was only achieved because the circuit was a complete dead short. In the case of your test pin you are somewhere in between high impedance and a dead short, and as such, you will see both less voltage and less current.

Additionally, your design would be wise to include protection devices such as TVS diodes. These nonlinear devices will start to clamp the voltage driving the current higher. If this seems rather vague and unspecific don’t worry.

Pin injection can be calculated and simulated quite easily.

Analysis of Indirect Lightning

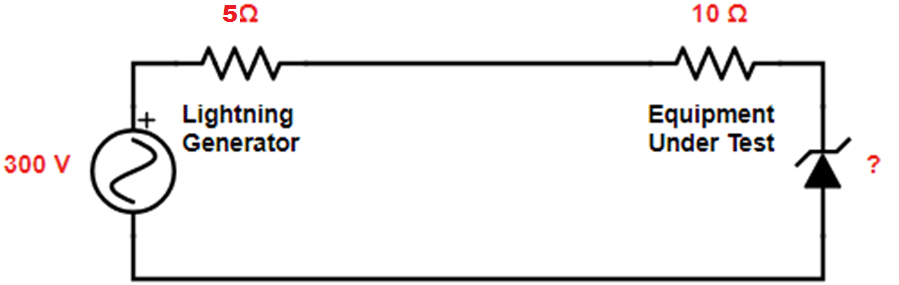

To calculate pin injection on your unit, you need to know a few things. The first thing you need to know is the transient generator’s test level and source impedance. For category A4, waveform 4 is applied. At level 4 it has a VOC of 750 V and an ISC of 125 A. This is equivalent to a voltage source of 300 V with a 5-ohm source impedance. To determine the source impedance simply divide the VOC by the ISC.

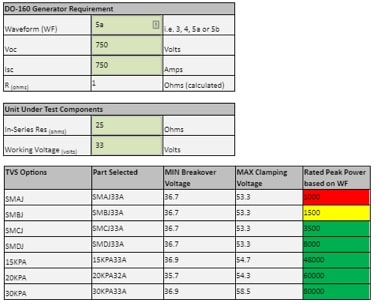

The next thing you need to know is your unit’s series impedance and the TVS you will use to protect your device. In the example seem in Figure 4, we will use a 10-ohm series impedance and will be trying to select the proper TVS.

Figure 4: Example of WF5a Level 3 Pin Injection

Calculating Peak Pulsed Power for DO-160 Pin Injection

First, we need to decide what working voltage we want in a TVS. For instance, if there is nominally 28 V on a discrete input, we should use a TVS with a working voltage above 28 V (say 33 V).

The second thing we need to do is select the size of the TVS (SMAJ, SMBJ, SMCJ, etc.) To solve the equation and select the properly sized TVS, we need to solve for peak pulsed power in the TVS. And to find the peak pulsed power we need to make an assumption about the TVS.

Because the TVS is a nonlinear device we must assume the clamping voltage of the TVS. In this case we assume the TVS is being stressed to the max. As such, we use the maximum clamping voltage specified on the TVS datasheet. With this assumption, we can solve the equation and determine the peak pulse power seen at the TVS.

IˆPULSE=(VˆSOURCE−VˆTVS_CLAMP)(?SOURCE+?EUT)

IˆPULSE=(750V−53.3V)(5?+10?)=46.44A

PˆPULSE= IˆPULSE∗VˆTVSCLAMP=2475 Wˆ

Now that we have peak pulsed power it’s time to find the proper TVS. And don’t just look at the front page of the TVS datasheet.

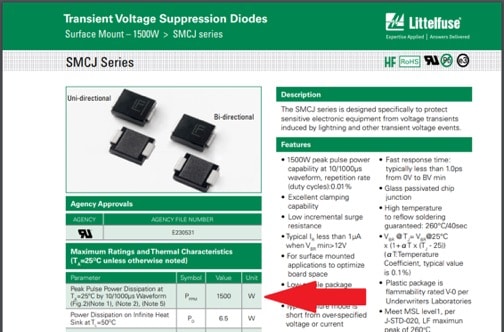

In Figure 5, we can see the SMCJ datasheet is specifying a peak pulsed power dissipation of 1500 W. Don’t be fooled by this number, this is the rating to the 10/1000 µs waveform. The waveform that you need to consider is DO-160 waveform 4. To do this we need to convert the 10/1000 µs waveform shown in Figure 6, to the DO-160 waveform 4.

Figure 5: Littelfuse SMCJ Datasheet

Translating 10/1000us WF to DO-160

All TVS data sheets specify a peak pulsed power using a 10/1000 waveform or some other common waveform. You must translate the power handling capability of the TVS from the waveform specified on the datasheet (10/1000 µs) to the waveform in your application.

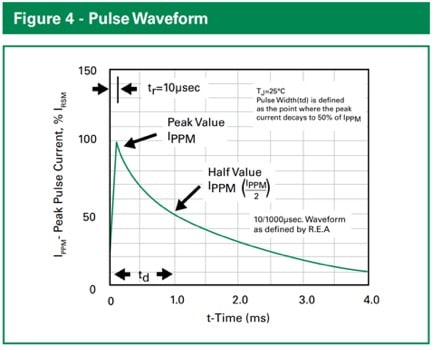

The specified waveform, 10/1000 µs, is typically shown on the datasheet. In Figure 6, you can see that the rise time of the waveform is 10 µs and the half value is 1000 µs. Thus, the name 10/1000 waveform.

Figure 6: 10/1000us waveform example from Littelfuse Datasheet

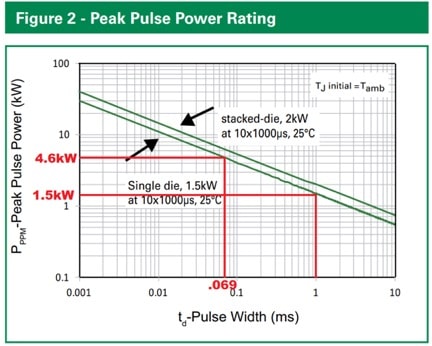

To translate to your waveform simply scroll down to the peak pulsed power rating graph. Here you can see that at the half time of 1000 µs (1 ms) the TVS is rated for 1.5 kW just as specified on the front page. However, waveform for has ½ time of 69 µs. You can use the graph in figure 7 to understand the peak pulsed power rating at 69 µs. In this case the TVS can handle 4.6 kW.

Figure 7: Peak Pulse Power Translation Example

Selecting a TVS for DO-160 Pin Injection

Now that we have calculated the peak pulsed power rating of the TVS at the DO-160 waveform 4 duration, we can determine if it is properly rated.

Based on our calculations here we determine that the SMCJ33A can handle 4.6 kW during a waveform 4 pulse. We also determined that the TVS will see 2.475 kW. This means that the TVS is both properly rated and has margin.

However, if you didn’t select the correct TVS the first time you may go through multiple iterations of changing the resistance and the TVS to get a circuit that works. However, you can use free tools provided by AerospacePal.com to find the answer in just 30 seconds.

AerospacePal’s free online Pin Injection Calculator allows you to put in your DO-160 requirement as well as specify several pre-loaded TVS devices.

Over 400 TVS devices can be analyzed in this tool. The tool will calculate both the required peak pulsed power as well as the handling capability of the selected TVS. Additionally, it will flag the part red if it is underrated, yellow if it is marginal (less than 20% margin) or green if it has more than 20% margin. Plus, the tool will also suggest pulse resistors for you application. Figure 8 shows an example of the tool.

Figure 8: AerospacePal.com Free DO-160 Pin Injection Calculator

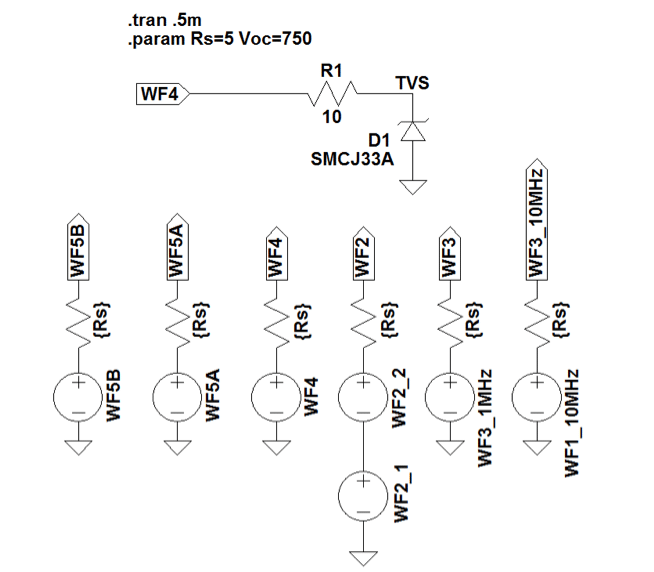

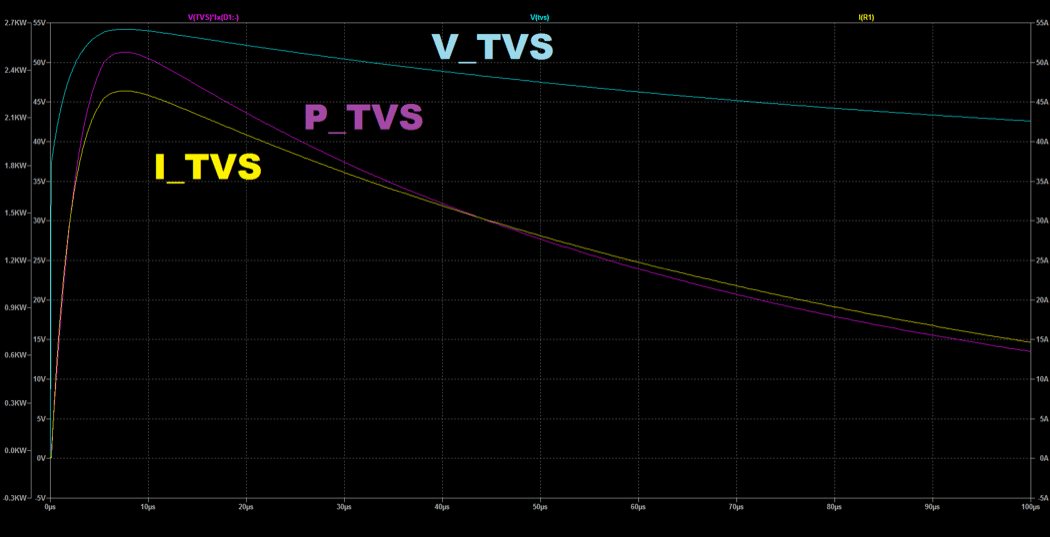

Simulating DO-160 Pin Injection

Since DO-160 waveforms are faster than the TVS specified 10/1000 µs waveform, there are slight inaccuracies in doing these calculations. One example can be that the mass clamping voltage of a TVS may go higher than the specified rating on the TVS datasheet. This is because the TVS inherently has inductance. With a faster waveform a higher voltage will build up across the TVS. Since peak voltage and current is used to calculate the peak power, this will result in a slightly different answer.

This kind of detail is something that is best seen in simulation.

To simulate this type of event you need to both construct the exponentially decaying pulse waveforms as well as find and download the proper TVS models. Alternatively, you could go to https://aerospacepal.com/160-indirect-lightning-ltspice-simulation-example/ and download in LTspice simulation see in Figures 9 and 10, where this is already been done. And it’s free!

Figure 9: AerospacePal.com LTspice Simulation Schematic

Figure 10: AerospacePal.com LTspice Simulation Results

Once you download the DO-160 indirect lightning LT spice example you can simply run the simulation and see the results. Then just modify the waveform resistor and TVS device to your application.

Another benefit to simulating your circuit, is that you will be able to understand the voltage the TVS is able to clamp given the pulse applied. You can then determine if your downstream circuitry will survive.

Remember to simulate both positive and negative pulses of all waveforms in your requirement. It is not always intuitive what the results will be. Check out these top five mistakes before selecting a TVS for your application.

DO-160 Pin Injection Summary

Though pin injection can be a difficult requirement to pass, the results should not be unexpected. With the methods and tools provided here, you should be able to quickly and accurately calculate and simulate DO-160 pin injection. If you have any questions about DO-160 Indirect Lightning best practices, please reach out to me at patrick@aerospacepal.com. After all, DO-160 Section 22.0 Indirect Lightning is the most failed section in all of DO-160.