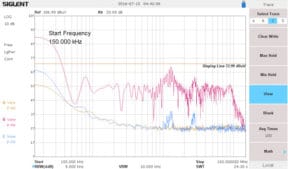

Figure 4 – The results with the 100 uH inductor installed (blue trace) looking from 150 kHz to 150 MHz. The red trace is the unfiltered noise and the yellow trace was the ambient baseline noise. The display line is the approximate emissions limit.

DC-DC Converter Noise Evaluation