Mart Coenen, EMCMCC bv, Eindhoven, the Netherlands

Hugo Pues, Melexis NV, Tessenderlo, Belgium

Thierry Bousquet, Continental, Toulouse, France

ABSTRACT

Though the automotive RF emission and RF immunity requirements are highly justifiable, the application of those requirements in an non-intended manner leads to false conclusions and unnecessary redesigns for the electronics involved. When the test results become too dependent upon the test set-up itself, inter-laboratory comparison, as well as the search for design solutions and possible correlation with other measurement methods, loses ground. In this paper, the ISO bulk-current injection (BCI) and radiated immunity (RI) module-level tests are discussed together with possible relation to the DPI and TEM cell methods used at the IC level.

Keywords: Bulk Current injection (BCI), Radiated Immunity (RI), Direct Power Injection (DPI), TEM cell, wire harness, automotive module, Electronic Control Unit (ECU) and Electronic Sub-Assembly (ESA)

INTRODUCTION

The increasing use of electronics in vehicles requires a very high level of reliability to assure the safety of the vehicle occupants as well as all other road users. Aside all mechanical vibration, thermal and moisture requirements, the new sensors and active actuators used have to be robust against the electromagnetic threats which originate from causes both within and around the vehicle. Already in the past, RF emission and immunity requirements were set by ISO, in particular by TC22/SC3/WG3 who deals with electromagnetic interference. Due to the growing use of these requirements, it is increasingly important to avoid faulty application and interpretation of them. This has a two-fold drawback:

- Module compliance doesn’t necessarily mean in-vehicle compliance after integration and

- Compliance to over-testing over a large range has an inverse impact on economics

The playing field is wide and involves car-manufactures as well as the Electronic Control Unit (ECU) and Electronic Sub-Assembly (ESA) manufactures, down to the silicon design to achieve a more integral economic solution.

New vehicle developments like using non-conductive composite materials, ‘zero emission’ exhaust requirements for combustion motors, the introduction of the hybrid motor or full electric vehicle put an ever higher burden on economics as well as safety reliability for the electronics used.

The RF immunity requirements have therefore been extended beyond the 30 V/m, in the 20 – 1000 MHz frequency range, as specified in the European Automotive Directive 2004/104/EC with its many amendments [1].

Most car manufacturers use extended immunity requirements downwards from 20 MHz to 150 kHz, typically by using the bulk current injection (BCI) test method. Where the highest level according the standards is 100 mA, levels up to 600 mA are already specified by some car-manufacturers. BCI test set-up drawbacks and pitfalls are described in chapter II.

100 V/m has been set as typical radiated immunity (RI) requirement for non-safety related ECU/ESA and 200 – 600 V/m for those ECU/ESAs which are safety related. The frequency range for the radiated emission and immunity of applications has been extended upwards from 1 GHz to 2 or even 6 GHz. This will be elucidated in chapter III.

In chapter IV, the necessary conditions to obtain possible correlation with IC test methods will be given and conclusions will be given in chapter V.

BCI TEST SET-UP

An RF-impedance undefined load simulator box is prescribed in-between the cable harness to the DUT and the ANs. The BCI probe shall be placed at distances, d, from the connector of the DUT; 150, 450, 750 ± 10 mm for the open-loop method and 0,9 ± 0,1 m for the closed-loop method. If a current measurement probe is used during the test it shall be placed at 50 ± 10 mm from the connector of the DUT. The calibration of the BCI clamp is described in detail in the latest version of the standard [2, 8, 9].

With the BCI test, there are 2 options implemented: ‘open loop’ and ‘closed loop’. With the ‘open loop’ test, the voltage coupled into the calibration test jig to achieve the required current through a 50 W load (where the opposite side of the test jig is loaded with 50 W as well) is recorded and the forward power level is maintained during the immunity test while the injection probe is positioned at the 3 harness locations.

With the ‘closed loop’ test, the RF current is increased up to a level where the DUT fails or the current limit or the forward power limit is reached: 4x the nominal RF power as used during calibration to meet the induced current requirements.

However, the ‘open loop’ test method was intended to apply for non-grounded DUTs and the ‘closed loop’ should apply for grounded DUTs only (as RF currents will flow intentionally).

Applying a closed loop bulk current of 100 mA into a insulated sensor with a capacitance to the reference plane of 20 pF at 3 MHz would require an output power of nearly 1500 Watt from a 50 W RF generator when no power limit is applied. Applying the open loop test would only require 0,5 Watt, a difference of 35 dB in RF power.

The second pitfall comes in three: the length of the harness, the equivalent RF termination at both ends of the harness and the BCI clamp itself.

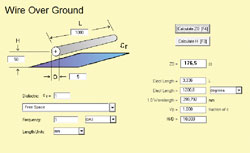

The cable harness above the reference plane represents a transmission line with a characteristic impedance of 150 – 200 W, Figure 1. Even in the ideal case when the cable harness is only terminated by two ANs to ground, being equal to 25 W in common-mode, there is a serious mismatch between the harness transmission line impedance and the ANs in parallel.

When a capacitor to ground is used for one of the (signal) lines in the load box circuit, the harness termination impedance mismatch will even be higher and standing waves over the harness will result.

On the opposite side of the harness, the DUT will be left floating or grounded. In either case, another ideal condition for resonances. However, these harness resonance frequencies are fully determined by the cable harness length which might include the wiring inside the load box up to the ANs.

The third item in this equation is the BCI clamp itself as the turn ratio between primary and secondary of this ‘transformer’ determines the resistive loading of the harness loop. Dependent on the frequencies designed for, the BCI clamp turns ratio also varies between manufactures, this between 1:1 and 1:5 which alters the equivalent damping resistance between 50 and 2 W (when excluding the RF losses of the clamp itself).

The length of the cable harnesses tested with varies between 1 – 2 meter determined by the specification of the end-user i.e. car manufacturer and has typically the same topology as used with the RI test set-up.

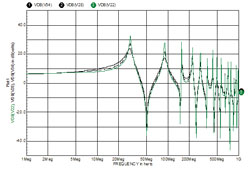

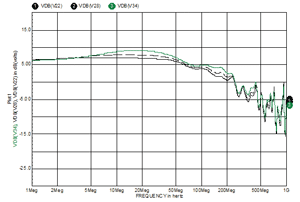

In the simulated results of figure 2, the DUT’s RF voltage towards the reference plane is given from a ‘floating’ sensor under the condition when the load box represents low RF impedance at the end of the harness. 0 dB represent the nominal voltage. Due to the open-ended transmission line, the induced voltage appears in full at the lower frequencies. This DUT to reference plate voltage, divided by the distance gives the local E-field strength. Excesses over 30 dB both above and below nominal can be noted which are also measured from the test set-up and can also be seen in real RF immunity test results, figure 3. The resonances occur at all harmonics of where the harness length equals n×l/4. When the cable harness is 2 meter long, the first resonance occurs at 37,5 MHz, see figure 3.

However, when the load box is replaced by a grounded network which represents, in total, the characteristic impedance of the cable harness, the influence of the current injection probe reduces as well as that the cable harness length related resonances and variation diminish: ≤ 3 dB, see figure 4. To enable these values in real vehicles, also the equivalent RF common-mode impedances at the ESA/ECU ports to the sensors connected have to be adapted to meet the cable harness characteristic impedances as well.

Only for the artificial BCI and RI test set-up, the cable harness will be used at 50 mm apart from a metal reference plane i.e. vehicle frame. In real cars, where the harness is routed against the vehicle’s frame characteristic impedances of 50 ± 20 W can be found. The common-mode termination to achieve best compliance with the test set-up will divert from the optimal impedances occurring in real vehicle applications.

RI TEST SET-UP

The RI test set-up, according ISO 11452-2 (2004) [3] defines that the cable harness (length 1,5 ± 0,1 meter) shall be positioned at 50 mm above a metal reference plane at 0,1 meter from the front edge of the metal plated table. The RI test is specified in the frequency range 80 MHz – 18 GHz. The antenna front is at 1 meter from the cable harness (0,9 meter from the metal plated table top and the antenna center is at the harness center. The metal plated table is defined 2 meter wide and 0,9 meter height above a conductive floor. The battery is still connected through an artificial network (AN). Also here the impedance undefined load box is defined in-between the cable harness to the DUT and the ANs.

The ISO standard reads: “The load simulator box shall be placed directly on the ground plane. If the load simulator has a metallic case, this case shall be bonded to the ground plane. Alternatively, the load simulator may be located adjacent to the ground plane (with the case of the load simulator bonded to the ground plane) or outside of the test chamber, provided the test harness from the DUT passes through an RF boundary bonded to the ground plane. When the load simulator is located on the ground plane, the DC power supply lines of the load simulator shall be connected through the AN(s)”. This open description allows for a very broad variety of RF impedances represented by the load box.

As result of different dimensions defined in the BCI and the RI standards, the widest metal plated table is used with a long cable harness. The cable harness is fixed at 50 mm above the metal plane and pretty undefined RF terminated by the load simulation box, which may or may not be grounded.

On the opposite side of the harness, the DUT shall be placed on an insulating support; also 50 mm height and the DUT shall be grounded by a ground strap (when defined by application).

When performing radiated immunity tests e.g. according IEC 61000-4-3, the E-field strength in front of the antenna is measured at 1 meter distance at center level, without any nearby object to the antenna. In the ISO RI case, the antenna is placed in front of the metal plated table which is at 0,9 meter distance as the distance to the cable harness has to be set to 1 meter. The E-fieldstrength is measured 0,15 meter above the metal plate at 0,1 meter from the edge without the cable harness present. The antenna height is adjusted such that the antenna center is also at the harness cable height: 0,95 m above the ground reference plane. For each frequency, the RF generator settings e.g. forward power is recorded to obtain the field strength at that single E-field sensor position.

Due to the close proximity of the metal table, the antenna’s radiation pattern is affected by mutual coupling. More problematic w.r.t. RI test result comparison is the antenna used as the formal antenna factor and gain factor are given for an antenna in free space. When high(er) gain horn antennas are used, the distance at which a plane EM field can be expected has to be multiplied by the gain factor. When the wavelength is 1 meter, the theoretical near-field to intermediate-field transition occurs at 1/(2p) meter distance. When the antenna gain is 12 dB e.g. with horn antennas, the distance to achieve this condition is 2 times further away as with a log-periodic antenna with a gain of 6 – 7 dB. The E-fieldstrength requirements can be met but the plane-wave conditions are not. As such, the local E-fieldstrength over the cable harness length has become antenna dependent thus unpredictable and non-calculable.

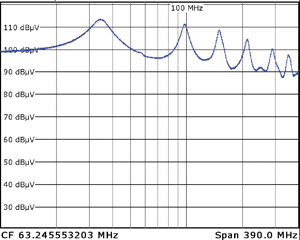

Similar to the BCI test set-up, the voltage i.e. current induced in the cable harness will depend on the RF termination at both ends of the harness. To verify this, a test set-up has been built using a horn antenna at 1 meter distance from the harness while sweeping through the frequency band from 400 MHz to 1 GHz. The antenna polarization was changed from horizontal to vertical while measuring the induced voltages in-between an insulated sensor and the reference plate. The worst case induced voltage was recorded and the load box impedance was varied between 1 and 200 W, see figure 5. What was already expected is that the maximum induced voltage reduces when the common-mode termination resistance at one end of the harness cable topology becomes terminated close to its characteristic impedance; 150 – 200 W in this case. Again this test set-up optimum common-mode termination impedance will be less in real vehicle applications.

The differences between the red and blue line results in figure 5 indicate that the worst-case resonances occurring under no-load conditions are substantially worse than when loaded with 50 W, by about 10 dB. In either case, the induced voltage decreases when the load box impedance is increased. No valid simulation model has been found yet to describe these cases.

POSSIBLE (COR)RELATION WITH DPI OR OTHER EMC IC TEST METHODS

Based on the lack of site-to-site correlation and the lack of sufficient bounds in-between the BCI set-ups, it will be very hard to find any correlation with DPI or TEM-cell results according IEC 62132-2, IEC 62132-4 or other test methods

[4 – 7]. What has remained from the measurements in the 80-ies is the relation between the E-fieldstrength applied to exterior of the vehicle and the levels of the induced currents obtained on the internal harnesses of the car which appears to be 1 mA/V/m.

When with BCI a current is applied of 200 mA, which across 50 W equals 10 Volt during calibration, this harness voltage, applied in “open loop control” will increase at resonance (worst-case) to about 200 – 300 Volt. Unfortunately, the same holds for “closed loop” BCI where due to the impedance at the sensor the local voltage may go to high extremes of > 500 Volt, as described earlier.

With the TEM cell test method as described in IEC 62132-2, only the IC itself will be exposed to EM-fields, none of the external components or the sensor front-end will be incorporated in the EM-field, unless the whole application board is applied on the 4 by 4 inch (or 100 x 100 mm) PCB structure as described in IEC 62132-1 [4]. The E-field applied will be RF voltage applied divided by distance between septum to outer enclosure, being 45 mm in a FCC TEM cell; a distance slightly less than the harness height of the BCI/RI test set-up.

When 5 Watt RF power is applied to the IC related TEM cell, terminated by 50 W, the inside E-fieldstrength will become 350 V/m, which is more than enough to satisfy the 200 V/m requirements but hardly enough when all the excessive voltages occurring at resonances have to be taken into account.

From figure 5 it can be derived that the maximum induced voltage from a 2 meter harness exposed to 200 Volt/m (in the frequency range 400 – 1000 MHz) will be 20 Volt when a low impedance termination at the load box is considered. This RF signal level divided by the sensor height above the reference plane of 50 mm yields 400 Volt/m, so slightly over 5 Watt RF power should be enough to satisfy this excessive condition (under the assumption that a large broadband horn antenna will be used rather than a log-per or any other type of antenna structure suitable in that frequency range). When the cable harness exposed is characteristic terminated in common-mode at the load box side, the worst case induced voltage reduces by 8 dB (2,5 x) which means that testing with only 160 V/m is enough; quite similar to what is occurring at the BCI/RI sensor position.

The DPI test is typically done by applying up to 30 dBm on the global pins (those port pins connected to wires leaving the PCB into a cable harness) and up to 12 dBm to the local pins (for those pins connected to local on-board components only). The coupling occurs from a 50 W source in series with a coupling capacitance of max. 6,8 nF or a value which can still be handled by the circuit connected to. For the CAN-bus interfaces, these RF voltages requirements have been raised even further to 36 dBm (4 watt; which equals 28 Volt RMS open voltage to an input or 40 Volts peak). Dedicated ESD protection structures need to be defined and special insulation techniques have to be used.

All RF voltages applied to each pin with the DPI tests are referenced to the common Vss/ground reference layer of the PCB. As such the delta voltages appearing on the PCB application have to be known between the various pins.

CONCLUSIONS

The present ISO standards carry many faces by their implementations; ‘open/ closed loop’, cable harness length, load box impedances, the grounding of the loading box as well as the DUT, etc. which leads to an ambiguous definition of these test set-ups, yielding severe differences in test results.

The ‘closed loop’ E-field measurement with the RI measurements close to the surface of the conductive table is incorrectly related on incident and reflective EM-field effects and therefore, together with the antenna chosen poorly correlated with EM-simulations. Also as different kind of antennas are allowed, these do yield differences in test results.

‘Open loop’ testing should be restricted to electrically ‘floating’ sensors and ‘closed loop’ testing shall apply to electrically grounded applications. The use of the ‘open loop’ and ‘closed loop’ testing shall be defined in the BCI standard in relation to how the DUT will be used in its application and not be left to the interpretation of an individual EMC test engineer or specification from a car manufacturer.

As real in-vehicle applications will deviate from the artificial ISO test set-up topologies, over-testing will not guarantee immunity compliance when the ESA/ECU will be integrated into a vehicle. The equivalent ESA/ECU RF common-mode impedance port definitions have to be aligned with the BCI/RI test set-ups or better vice versa, this to achieve comparable test data. Resonances in the test set-ups shall be avoided and equal measures shall be taken at the ESA/ECU ports also to avoid resonances while being integrated into a vehicle.

It is necessary to enforce (by standard) a unified AN (including the load simulation box) which is encapsulated into one metal box. This box shall be grounded to the reference plane and shall yield a defined CM output impedance at the ESA/ECU port of 150 – 200 W over the whole frequency range of application rather than 25 W (two ANs in parallel) again in parallel to the load box input filter topology in a limited frequency band.

Care shall be taken with the real characteristic common-mode impedance occurring in a vehicle which will be around 50 W and thus less that the artificial impedances one used with the test set-ups. Changing the cable harness height over the reference plane to achieve 50 W could be a better alternative but will require new evidence building compared to the data gathered over the last 25 years.

The induced RF voltages occurring from the BCI can be forecasted by an analogue circuit simulator for both ‘open’ and ‘closed loop’ measurement set-ups for the various application conditions of the BCI clamp. When the common mode termination impedances are set to the characteristic impedance of the cable harness under these test conditions, the turns ratio of the BCI clamps becomes close to irrelevant.

The root causes for the differences in test results in-between the BCI and RI test set-ups have been described and based on these findings the requirements for a TEM-cell or DPI test set-up can be adapted accordingly. The RF voltages induced from both the BCI and RI test set-ups could compare with the TEM cell and DPI test methods under the condition that resonances are avoided and common-mode cable harness impedance requirements are met. Fortunately, these two measures coincide in one action.

When the relations between the BCI/RI and the DPI/TEM- cell test methods become justified, earlier compliance to the requirements can be proven which then shortens development cycles by months and probably will reduce a substantial amount of non-predictable redesigns.

ACKNOWLEDGEMENT

The work carried out is supported by a Dutch Governmental innovation program WBSO, under number: ZT09051042.SO

REFERENCES

[1] Commission Directive 2004/104/EC of 14 October 2004 adapting to technical progress Council Directive 72/245/EEC relating to the radio interference (electromagnetic compatibility) of vehicles and amending Directive 70/156/EEC on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers (followed by numerous amendments)

[2] ISO 11452-4, Road vehicles — Component test methods for electrical disturbances from narrowband radiated electromagnetic energy — Part 4: Bulk current injection (BCI)

[3] ISO 11452-2, Road vehicles — Component test methods for electrical disturbances from narrowband radiated electromagnetic energy — Part 2: Absorber-lined shielded enclosure

[4] IEC 62132-1, Integrated circuits – Measurement of electromagnetic immunity, 150 kHz to 1 GHz – Part 1: General conditions and definitions

[5] IEC 62132-2, Integrated circuits – Measurement of electromagnetic immunity – Part 2: Measurement of radiated immunity – TEM cell and wideband TEM cell method

[6] IEC 62132-3, Integrated circuits – Measurement of electromagnetic immunity, 150 kHz to 1 GHz – Part 3: Bulk current injection (BCI) method

[7] IEC 62132-4, Integrated circuits – Measurement of electromagnetic immunity 150 kHz to 1 GHz – Part 4: Direct RF power injection method

[8] Experimental characterization of injection probes for bulk current injection, S. A. Pignari, F. Grassi, F. Marliani, F. G. Canavero, www.ursi.org/Proceedings/ProcGA05/pdf/EA.4(0494).pdf

A Critical Assessment of the Closed-Loop Bulk Current Injection Immunity Test Performed in Compliance With ISO 11452-4, Crovetti, P.S. Fiori, F, IEEE Transactions on Instrumentation and