Static Control gloves can be classified as Personal Protective Equipment (PPE) to reduce the risk of electrostatic discharge (ESD).

There are several types of ESD Gloves: Nitrile, Vinyl, Latex, Rubber and humidity independent conductive carbon/nylon yarn gloves as illustrated in Figure 1 above.

Due to an astounding rise in the number of non-compliant and suspect counterfeit products, the author has found (in the testing of electrostatic materials) that a significant number of today’s OEMS, CMs, and suppliers either manufacture and/or use many ESD safe products that do not meet current ANSI/ESD or Military Standards. Suspect counterfeiting is no longer limited to cosmetics, watches and hand bags; this problem extends to the cordless wriststrap, soldering irons, ionizers, static shielding bags and other static control products.

Since 2007, non-compliant or suspect counterfeit materials have infiltrated the supply lines of Federal agencies and the commercial sector. First to present and publish on ESD Materials and Packaging used in the DoD supply chain, the author spoke before the 2010 NASA Quality Leadership Forum, Cape Canaveral prior to Industry awareness of suspect counterfeit static control products found in manufacturing.

Today’s manufacturing sector requires ESD protection of ultra-sensitive electronic Class 0A sensitive devices at <125 volts. ESD handling protocols are also required with medical devices, small satellites (CubeSats), pharmaceutical delivery, touch screen displays, consumer electronics and aerospace & defense.

Following a formalized materials qualification process is critical in sourcing of ESD materials from the manufacturing floor to long term storage, transport and staging. Moreover, the end user must take a “Trust but Verify” posture and require evaluation samples from suppliers for qualification testing.

This article does not address cleanroom gloves. In the handling of sensitive devices, some people are latex intolerant and others may be allergic to antistatic gloves that could contribute to skin irritation. Moreover, migration of topical surfactants could pose issues with circuit card polycarbonate incompatibility, mirror fogging, solderability and crazing or stress cracking[1]. For this evaluation, the ergonomically designed and breathable static control gloves prevent profuse sweating, are washable and maintain ESD safe properties at low RH.

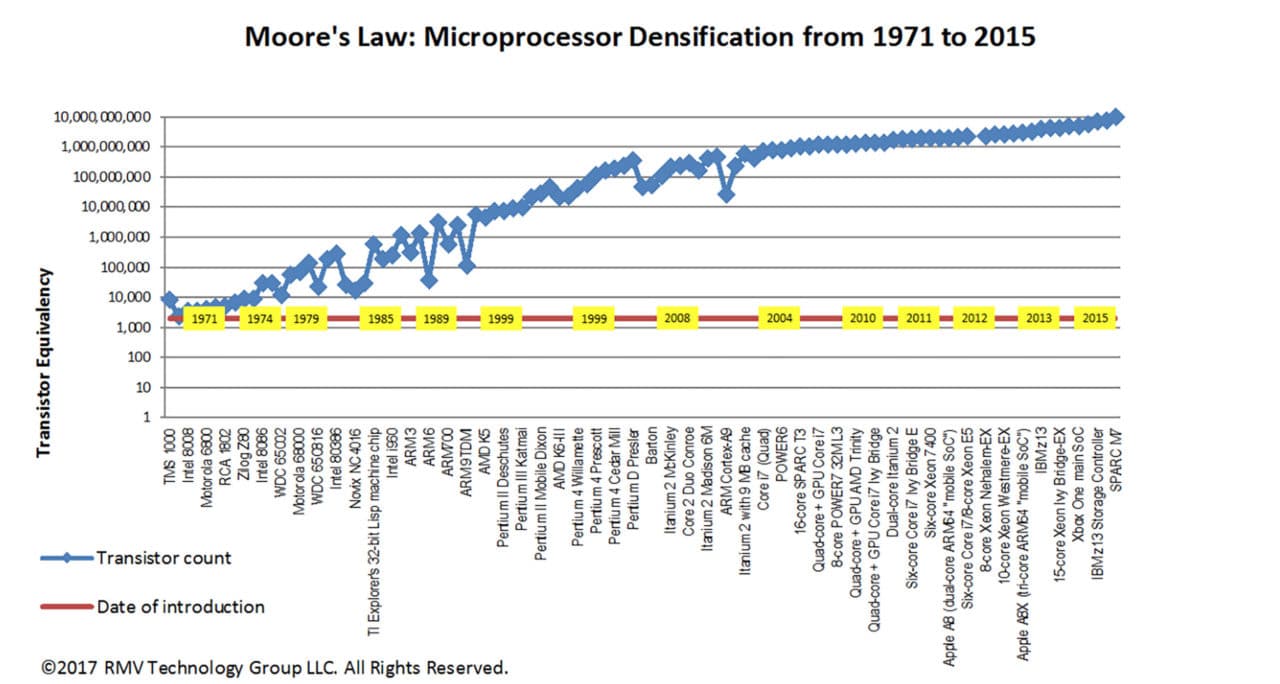

As of 2016, the highest transistor count in a commercially available Intel 22-core Xeon Broadwell-EP is now over 7.2 billion transistors equivalency compared to Intel’s 2300 transistors in 1971[2] (Table 1). Simply put, speed kills. ESD procedures for the protection of ultra-sensitive devices are necessary to prevent damage or yield loss in the field after release of the final product.

During assembly, ANSI/ESD S20.20-2014 ESD protocols are now being implemented so that supplier products will provide traceability with recent testing requirements.

How does one evaluate static control PPE gloves? There are two basic testing methods, ANSI/ESD SP15.1-2011 and MIL-STD-3010C, Method 4046 (modified).

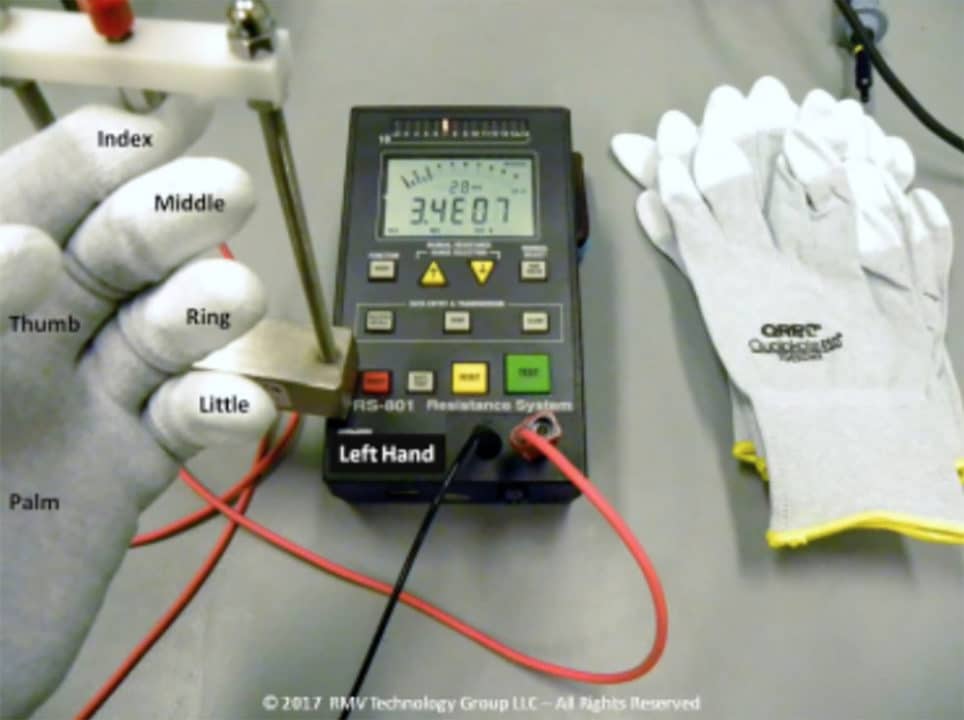

Two testing methods are commonly utilized in Aerospace & Defense, Semiconductor, Disk Drive, Medical Device and the Automotive sector. One method is ANSI/ESD SP15.1-2011 (Café) that measures a glove’s resistance when worn by an individual (Figure 2, left); the second method is electrostatic decay testing at +/-1000 volts to +/-100 or less (Figure 2, right).

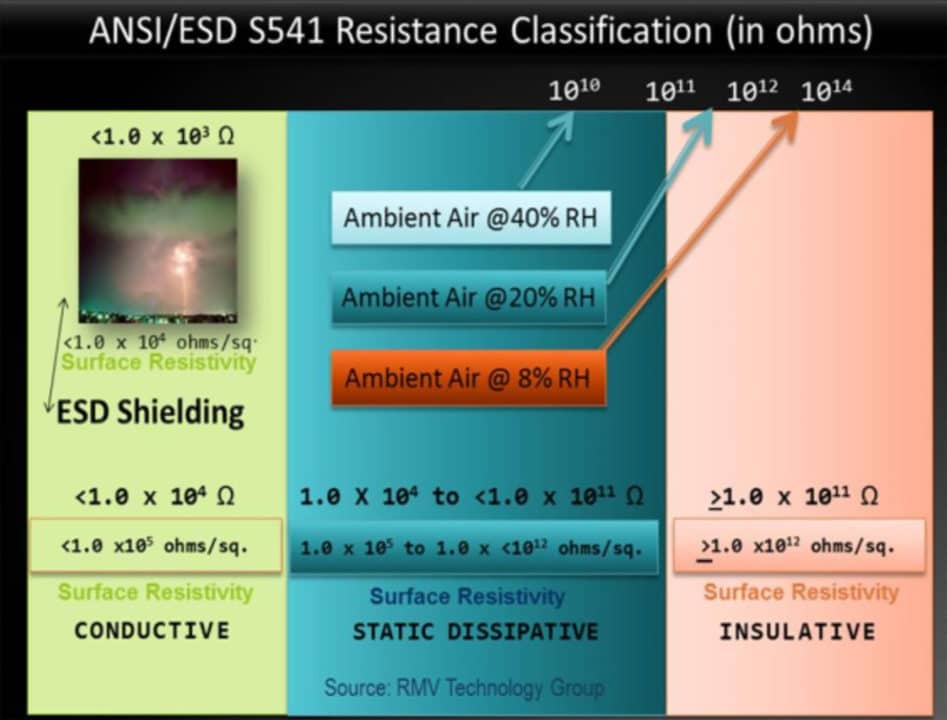

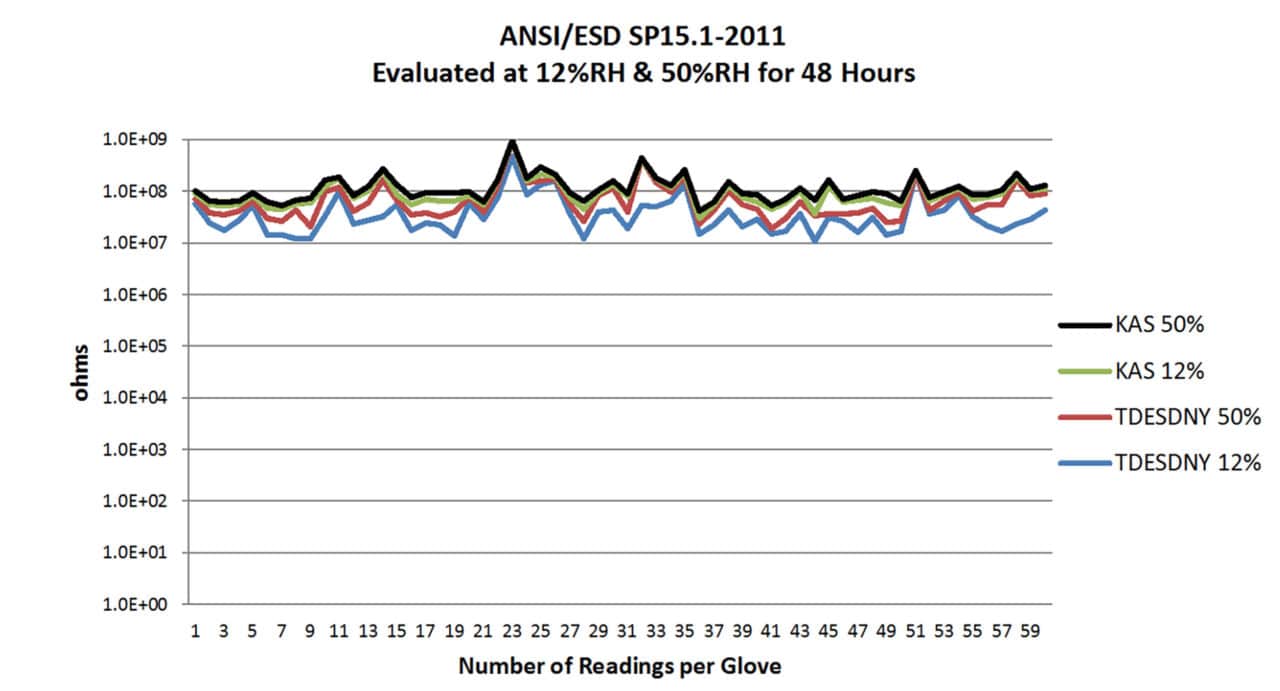

As the reader can see from the Illustration in Illustration 1 above, there is a relationship between relative humidity (RH) and surface resistance. Most organizations follow the ANSI/ESD S541-2008 surface resistance cut-off limit of <1.0 x 1011 ohms for ESD PPE gloves that serves as the benchmark for performance.

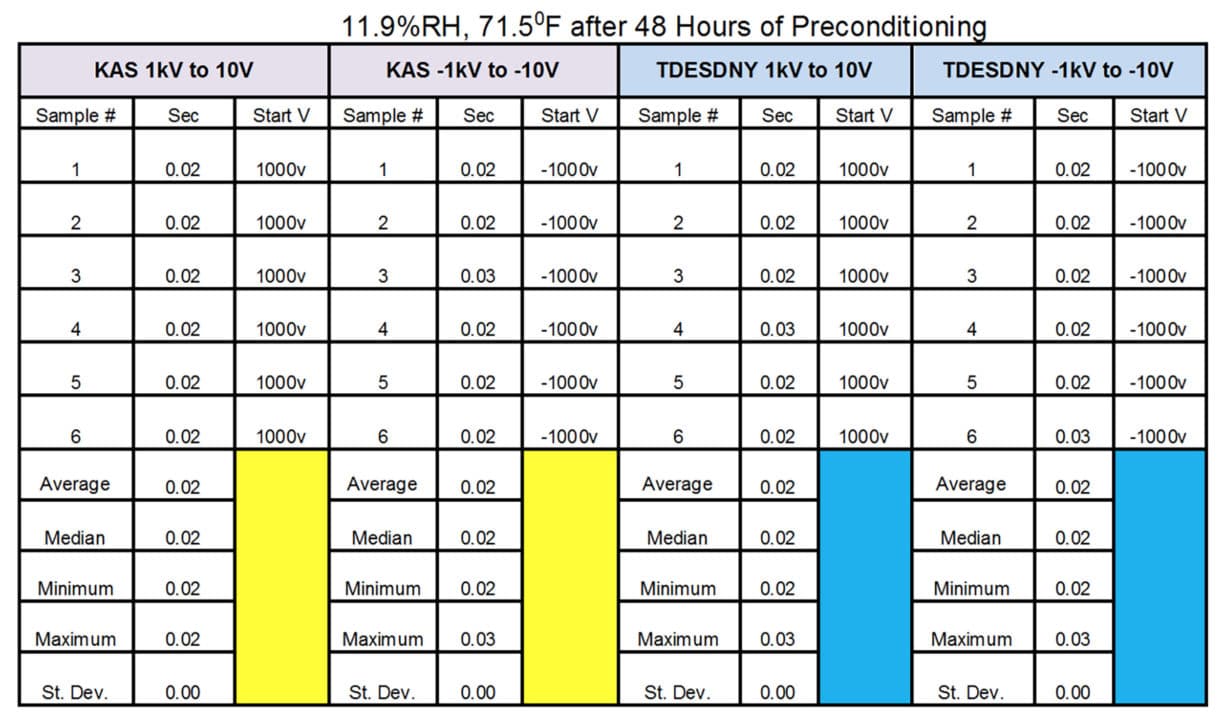

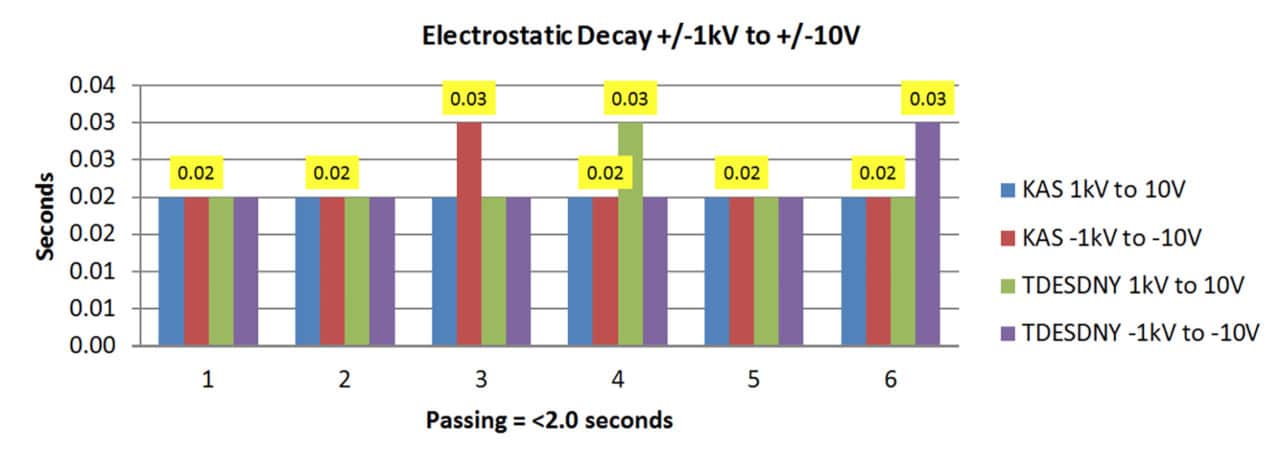

A cut-off of <2.0 seconds is a well accepted limit for electrostatic decay testing that can be traced back to EIA 541, Appendix F (1988). In this case, the test setup is positioned at +/-1000 volts for decay down to +/-10 volts.

One advantage of the ANSI/ESD SP15.1 Café resistance testing method is the measurement of multiple contact points with (10) per pairs of static control gloves (little finger to thumb) as illustrated below in Figure 3.

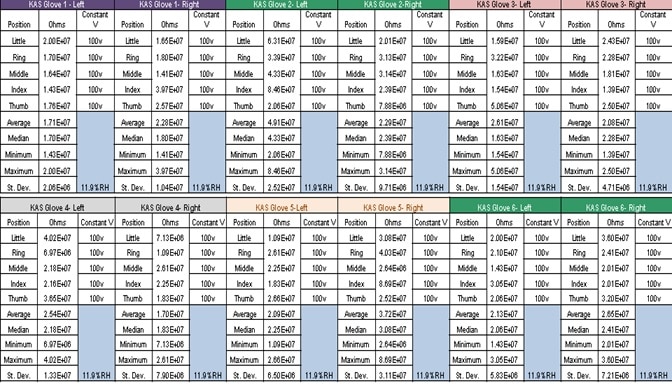

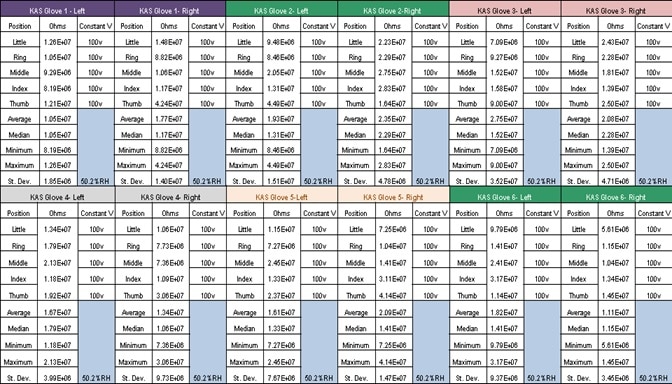

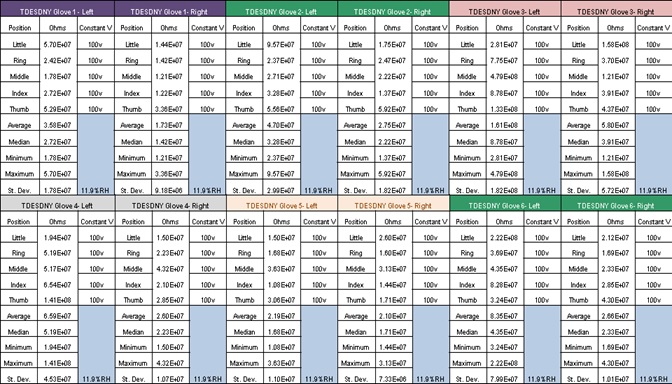

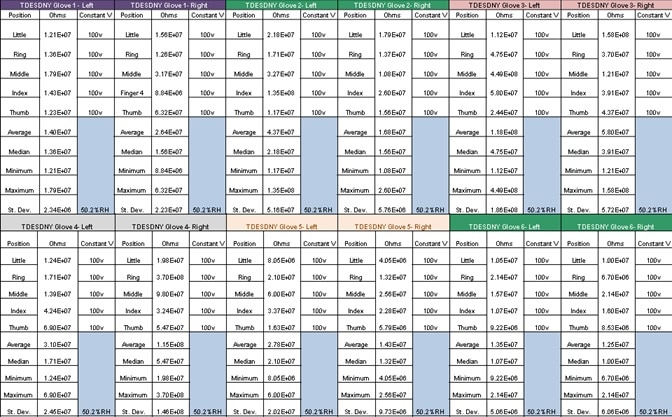

ANSI/ESD SP15.1 provides an evaluation method to analyze how gloves will interact when worn by testing six pairs. In this test setup, gloves were evaluated at 12%+/-3%RH and 50%+/-3%RH after 48 hours of preconditioning as illustrated in Tables 2 – 6.

The reader can observe in Table 6, that the static control PPE gloves performed under the upper limit of <1.0 x 1011 ohms. Some companies that test for Charge Device Model (CDM) safety set a target range between 1.0 x 106 ohms to 1.0 x 109 ohms in which the gloves in this article under test achieved.

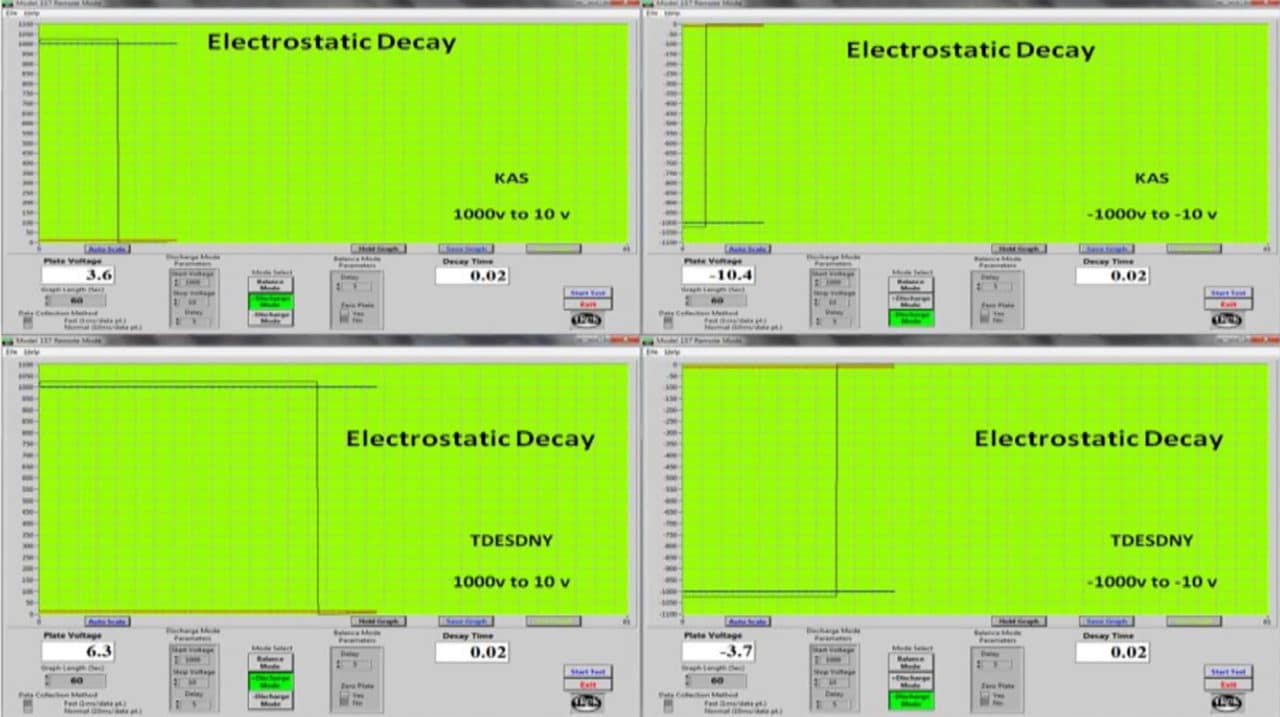

A second method utilized for Static Control PPE verification is to conduct charge decay tests for six gloves at 12%RH+/-3%RH after 48 hours of preconditioning. For this test, a grounded evaluator wears the gloves making intimate contact with a 6” x 6” stainless steel plate charged to +/-1.0kV then initiating decay for a cut-off of +/-10 volts. In each case, the decay measured less than 2.0 seconds and can be viewed in Tables 7 – 8.

In short, if the reader utilizes both the ANSI/ESD SP15.1 and Electrostatic Decay per MIL-STD-3010C, Method 4046 (Modified), then one can be assured that 3rd party or in-house testing results will confirm a supplier product claims and reduce the risk of suspect counterfeit static control products in the supply chain.

Special Acknowledgement: A special thank you to Duncan Casselman Duncanc@qrpgloves.com) who generously provided samples of QRP KAS & TDESDNY gloves for this article.

References:

ANSI/ESD SP15.1-2011

MIL-STD-3010C, Method 4046

ANSI/ESD S20.20-2014

ANSI/ESD S541-2008

LATEX ALLERGY OVERVIEW, AAAAI, http://www.aaaai.org/conditions-and-treatments/allergies/latex-allergy

[1] Electronic Part Damage by Antistat Vapor, John Kolyer, Ph.D., Arie Passchier, Ph.D. and W.G. Peterson, Boeing, 2001.