A brief introduction…

Keith Armstrong, Cherry Clough Consultants, Brockton, Stafford, UK

This new publication (August 2008) EMC for Functional Safety published by the Institute of Engineering and Technology (IET) replaces the IEE’s 2000 edition. The Guide comprehensively describes practical and cost-effective procedures that can be utilized by both management and engineering to help save lives and reduce injuries, wherever electronic technologies are used in safety-implicated products, systems, or installations of any type.

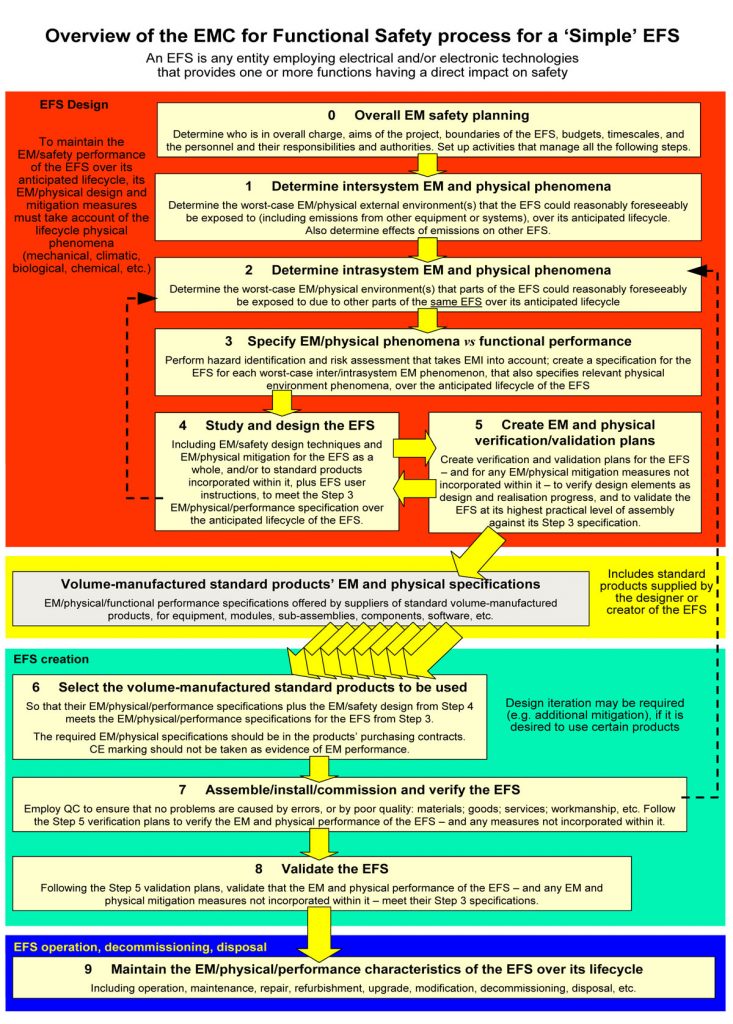

The figure below shows the nine basic steps employed by the Guide, which includes checklists to aid project management, design, and compliance assessment.

The ever-increasing complexity of electronics, along with the continuous miniaturization of the feature sizes in silicon integrated circuits, has rendered the normal testing-based approach to EMC inadequate in regard to safety. Consequently, the new discipline of “EMC for Functional Safety” has recently been developed to help maintain tolerable levels of safety risks.

Many EMC and safety engineers still believe that if the normal immunity tests have been completed successfully, that all safety concerns have been allayed as well. Others harbour the illusion that applying the normal tests at increased, more stringent levels will provide a “safety margin”. Unfortunately, relying on such EMC testing alone is much too simplistic for modern electronic control systems because it ignores most of the EM interference issues that can influence safety risks.

To demonstrate that the design of a product, system, or installation will be safe enough despite the reasonably foreseeable EM disturbances that could occur during its lifecycle, we must now use Risk Management methods from the International Electromechanical Commission. Specifically, the new Edition 2 of IEC TS 61000-1-21 (due to be published before the end of 2008) includes these methods.

The IET’s new Guide is a detailed and practical application of IEC TS 61000-1-2 Ed.2, which is written in the language of IEC 61508 (the IEC’s basic standard on Functional Safety) so that it can be used as 61508’s “missing EMC Annex”. Other functional safety standards such as the International Standard Organization’s (ISO) 14971 (medical) or the draft ISO 26262 (automotive) use different ‘languages’ to describe the same basic principles—so the IET’s Guide has been written to be universally applicable, regardless of which functional safety standard (or none) is applied.

EMC issues that must be taken into account during risk assessment include reasonably foreseeable faults or misuse; agreeing and wear; component tolerances; physical stresses; and climatic exposures that can affect EMC characteristics, along with a wide range of EM disturbances.

The risk assessment must take into account EM disturbances that can be expected to occur incidentally during the lifecycle of an electronic product or installation—for example a transient, an electrostatic discharge (ESD) signals from a nearby cell phone, a distorted AC mains waveform, or continuous RF field. It must also account for combinations of stresses that can be expected to arise spontaneously some time during the lifecycle—for example, a high ambient temperature, an AC mains waveform distortion, a transient or ESD, or signals from a nearby cell phone combined with at least one fault or misuse, along with wear and ageing (such as corrosion).

The traditional approach to EMC is based solely on passing a fixed set of tests that apply one EM disturbance at a time in a benign environment. Clearly, this approach is inadequate for demonstrating that tolerable safety risks will be achieved over the lifecycle. Any attempt to demonstrate tolerable functional safety risks based solely on EMC testing would require an unimaginably large test plan that would cost more than anyone could possibly afford! The solution is to design a product using a risk management approach along with a variety of verification and validation measures, such as design assessments, as well as some tests that have been carefully targeted for the specific design and its application.

This same ‘untestability’ problem has already been faced by the safety-related software industry, which developed the necessary design, verification, and validation techniques (including some testing) during the 1990s. Now we are seeing a similar development in the new discipline of “EMC for Functional Safety,” and the IET’s new Guide provides detailed and practical assistance.

Manufacturers that apply this Guide should benefit from lower financial risks because improved immunity to EMI should significantly reduce the number of warranty returns/repairs and product liability lawsuits. Also, the Guide’s procedures reverse the usual routine and require the use of EMC expertise from the very start of a project—as compared to the usual approach of designing or assembling with little attention to EMC, then fiddling around until the EMC tests are passed. Additionally, employing these procedures should help manufacturers get to market more quickly with lower overall manufacturing costs, and real financial savings can generally be expected when this Guide is correctly applied.

REFERENCES

1. IEC TS 61000-1-2 Ed.2 “EMC – Part 1-2: General – Methodology for the achievement of functional safety of electrical and electronic systems including equipment with regard to electromagnetic phenomena”

Note: The IET/s Electromagnetic Compatibility for Functional Safety is now available for free download, and as a reasonably priced book, from www.theiet.org/factfiles/emc/index.cfm.

Keith Armstrong graduated from Imperial College, London in 1972 with an Honours degree in electrical engineering. He has been a member of the IEE (now IET) since 1977, a UK Chartered Engineer since 1978 and a Group I European Engineer since 1988. He founded Cherry Clough Consultants in 1990 to help companies reduce timescales, warranty costs and other expenses while complying with the EMC Directive and other international standards and regulations.

Currently, he chairs the IET’s Working Group on “EMC and Functional Safety” and is the UK’s eam for IEC 61000-1-2 (RMC & Functional Safety). Keith can be reached at keith.armstrong@cherryclough.com.