Bryan Cole

President of Technology Research Council

Jim Tiesi

Marketing Manager for Emerson Network Power Surge Protection

Electrical systems and equipment that power and control industrial, commercial, telecommunication and medical processes are subjected to numerous power quality events. These includes power disruptions, brown-outs, sags, swells, temporary overvoltages and lightning. Lightning can disrupt processes by damaging transformers, distribution equipment, conductors or power conversion equipment. Lightning can also disrupt processes by activating protection and control relays within the utility system, which can cause transient conditions which could result in switching transmission and distribution relays to re-route electrical power.

Integrated SPD

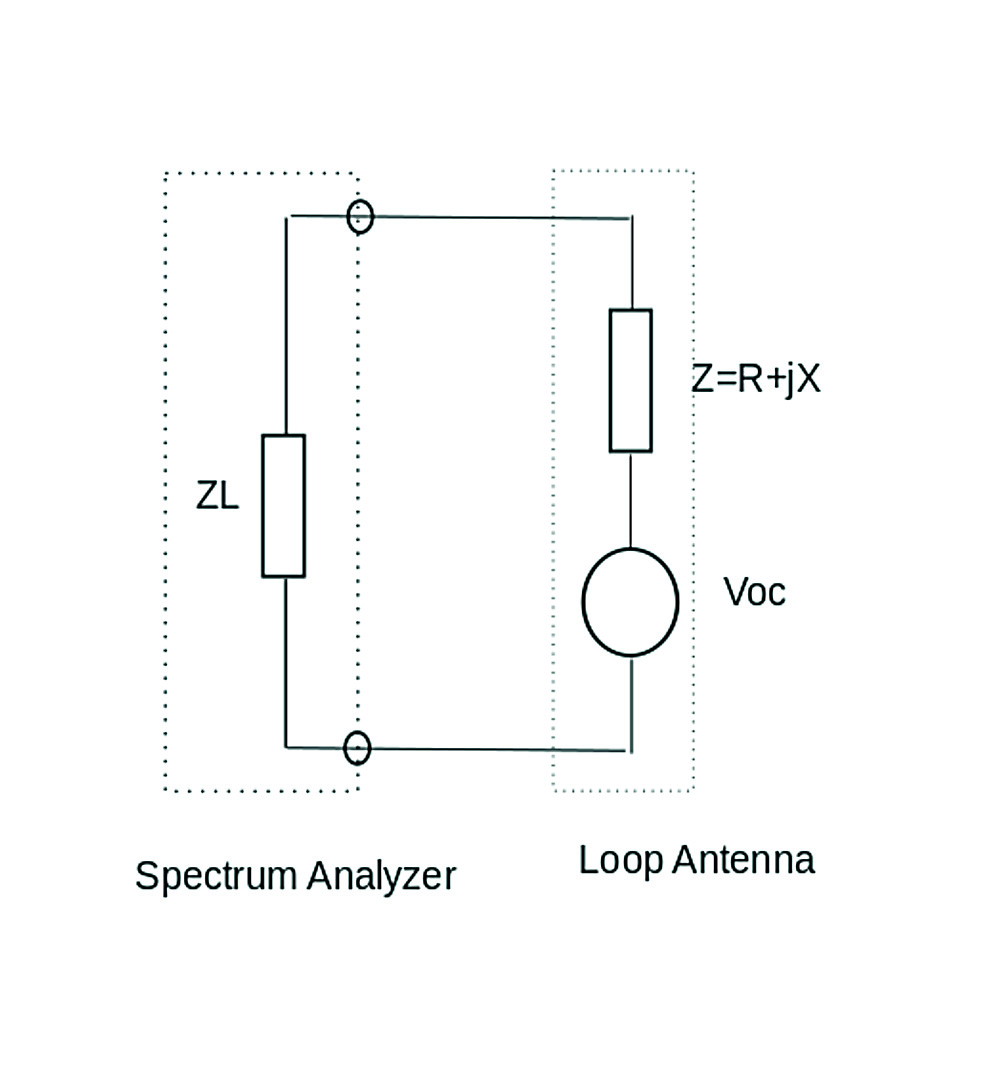

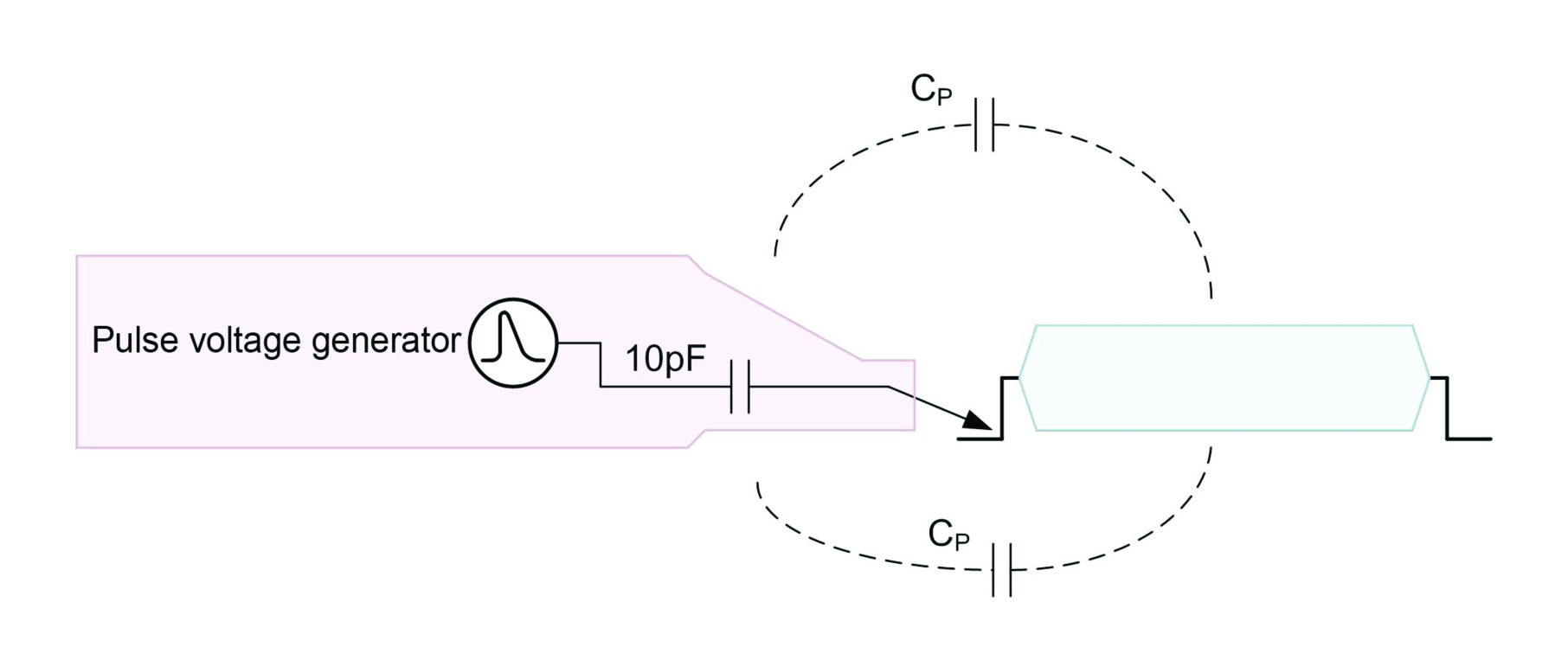

To protect electrical systems and equipment from lightning induced transients, surge protective devices (SPDs) are connected to the electrical system. An SPD is a device that contains at least one non-linear component and is intended to protect the electrical system and equipment by limiting transient overvoltages and diverting surge currents [1]. SPDs come in numerous configurations from small DIN Rail and flanged mounted devices intended for installation inside electrical equipment and machines (Figure 1), to permanently connected devices intended to be connected external to electrical equipment and machines (Figure 2).

External SPD

SPDs need to protect the electrical system without adversely affecting the overall system or cause harm to adjacent personnel. Adverse interactions include system resonances, interactions with ground fault systems, and electrical system damage from inadequately applied (rated) equipment [2]. Protection is derived from the performance characteristics of the SPD. Performance attributes include limiting transient voltages by diverting transient current to amplitudes that are acceptable for continual operation of the connected equipment. The connection of the SPD to the electrical system should not subject personnel to additional electrical hazards from its operation: such as shock and arcing hazards.

SPDs & SHORT CIRCUIT CURRENTS

IEC standards require SPDs to withstand fault or short circuit currents from an internal SPD failure [1]. To ensure that an SPD is capable of withstanding the short circuit currents associated with a connection to the electrical system, the SPD is required to have a disconnecting device.

An SPD disconnector is a device that disconnects an SPD from the electrical system in the event of an SPD failure [3]. SPD disconnectors are required to provide system protection to two SPD failure modes: thermal faults and short-circuit current faults [3]. A short-circuit current is the amount of current that can flow in the system to the point of failure. The amplitude of the short-circuit current depends on numerous conditions, including the source impedance, conductor impedance, whether the fault is phase-to-phase or phase-to-ground, and the amount of other impedances in the electrical system.

SPDs that are connected to the electrical system are required to have a short-circuit current rating [1]. The short-circuit current rating of an SPD is the maximum prospective short-circuit current available from the electrical system that the SPD and disconnector is able to withstand without creating an electrical hazard [3]. For an SPD to be properly connected to the electrical system, the short-circuit current rating of the SPD must be equal to or greater than the short-circuit current at the point of installation [3, 4].

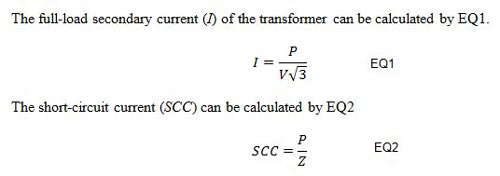

Calculating short-circuit currents in an electrical system is complex. While it can be performed by hand or through the use of spreadsheets, software simulation is commonly used to account for the many variables. However, estimating the short-circuit current at the output of a transformer can be easily estimated. To approximate the short–circuit current (SCC) at the secondary of the transformer, one needs to know the power rating of the transformer (P), the full-load secondary current of the transformer (I), the line-line voltage at the secondary of the transformer (V) and the transformer impedance (Z) [5]. The power rating is in kVA, the current is in amperes (A), and the voltage is in volts (V).

As the power rating of the transformer increases, the available short-circuit current increases. As the impedance of the transformer increases, the available short-circuit current decreases.

SPD SHORT-CIRCUIT CURRENT TESTING

SPDs are required to be tested to short-circuit currents to determine the short-circuit current rating (SCCR) [3]. A disconnecting device is required to disconnect the SPD during the short-circuit current test, except for the Neutral to Protective Earth (N-PE) protection mode of an SPD in a TN or TT grounding system [3]. The SPD disconnecting device can be either an internal or external fuse or circuit breaker.

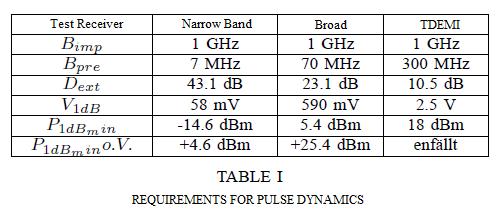

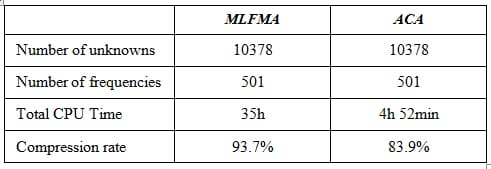

TABLE 1: SPD short circuit current ratings

The SPD manufacturer specifies the amplitude of the short-circuit current (Table I). If no short-circuit current is defined by the SPD manufacturer, then the SPD is tested at a short-circuit current of 300 A. Once the short-circuit current amplitude is selected, the power source must be able to deliver a specific current with a minimum power factor (Table II).

Prior to short-circuit current testing, samples must be prepared. For SPDs with voltage limiting components, e.g. metal-oxide varistors (MOVs) or silicon avalanche diodes (SADs), they are replaced with appropriately sized copper blocks [3]. SPDs that are intended to be connected inside an electrical enclosure or have a degree of protection of IP20 or less are installed in a mesh type, metal enclosure [2]. SPDs intended to be connected outside of electrical equipment are tested in the supplied enclosure.

After the short-circuit current test is completed, the pass criteria of the SPD are [3]:

- No visible damage to the SPD enclosure; small indents or cracks that do not degrade the degree of protection (IP code) are excluded

- Disconnection shall be provided by the disconnector

- Disconnector indication shall show proper state

- SPDs with a degree of protection greater than IP20 shall not have accessible live components (unless accessible prior to the test) when subjected to a test finger probe

- The short-circuit current from the power source shall be interrupted by the SPD disconnector within five seconds

- There shall be no explosion of other hazard

- There shall be no flashover to the mesh type, metallic enclosure

Table 2: Short circuit current and power factor [2]

SPD & DISCONNECTOR INTERACTIONS

Interrupting a short-circuit current produces an arc between the two electrodes or points in the electrical circuit. Circuit breakers incorporate arc shoots to direct the arc away from the contacts within the circuit breaker. Fuse elements use an arc quenching medium, e.g. vacuum, sand, etc., to ensure the arc between the two electrodes.

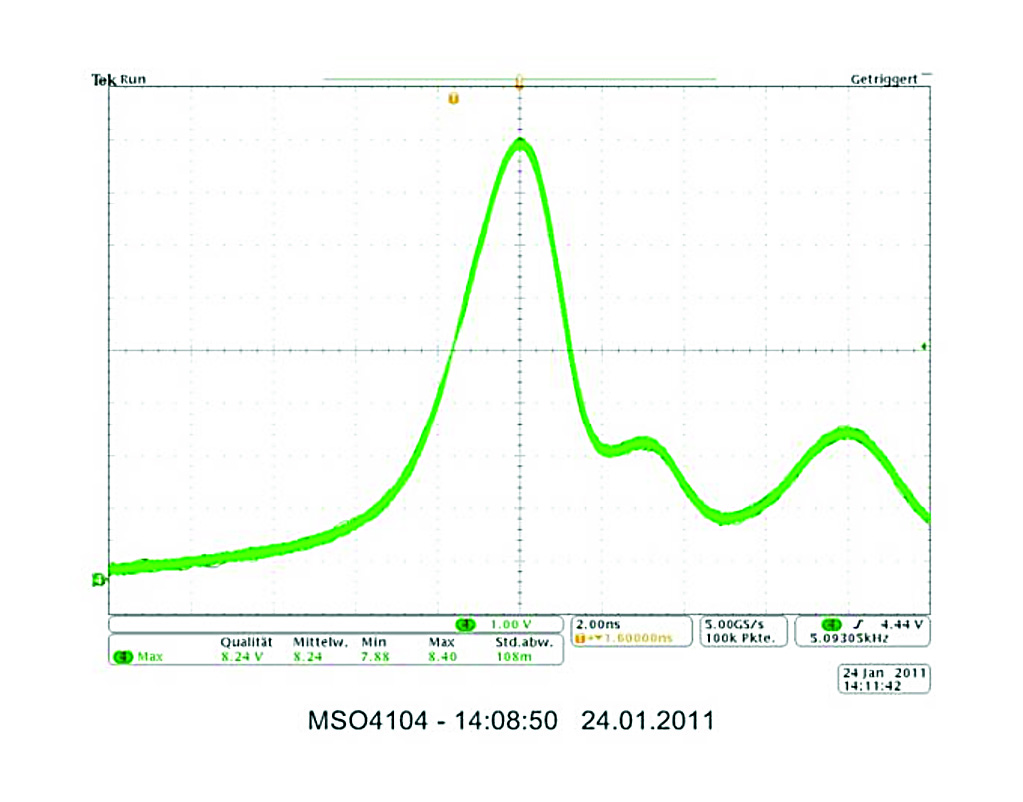

Some SPDs use internal disconnectors that are in close proximity to the voltage limiting component(s), i.e. MOVs. When MOVs are placed in close proximity to the internal disconnector intended to disconnect short circuit currents, the arc created can rupture the MOVs resulting in subsequent actions that will result in the SPD failing to meet the pass criteria (Figure 3).

SPDs subjected to the short-circuit current tests using a copper shorting block in place of the voltage limiting component meet the requirements of the standard. However, using a copper shorting block may not fully evaluate the overall safety performance of the SPD to adequately disconnect during short-circuit currents. Other international standards require that the SPD be tested as a complete function device [6].

When considering the installation of an SPD, a risk assessment is required to ensure that the SPD will provide the proper protection and disconnect from the electrical system without creating additional hazards [1]. This risk assessment should include an evaluation of how the SPD was tested to short-circuit currents and if the voltage limiting components were connected in the circuit or if they were replaced by copper blocks.

SPD APPLICATION EXAMPLE

Connecting the SPD to the electrical system requires that the short-circuit current at the point of installation and the short-circuit current rating of the SPD are needed. In all cases, the short-circuit current rating of the SPD must be larger than the calculated short-circuit current at the point of installation. If the SPD is located in other locations, a detailed short-circuit current study is required. If connecting to the secondary side of a transformer, simple equations (EQ1, EQ2) can be used in conjunction with the parameters of the transformer to determine the short-circuit current.

Improperly applied MOV & disconnector

For example, if an SPD is to be connected at a facility service entrance feed from a 2.5 MVA transformer with a voltage of 400Y/230 V, 4W+G, and an impedance of 3 %, using EQ1 and EQ2 yields a short circuit current of 120.3 kA. To properly apply the SPD, the SPD would have a short-circuit current rating of 125 kA or more. Applying an SPD with a short-circuit current rating of less than 125 kA would compromise the safety of personnel.

CONCLUSION

The application of SPDs on the electrical system is an effective and important method to reduce damage to the electrical system and equipment from transient voltages. Properly applying SPDs requires the engineer to consider many system and equipment parameters. One important parameter is the short-circuit current rating of the SPD, the type and location of the SPD disconnector, and the short-circuit current at the point of application. The short-circuit current at the point of application can be calculated using the process shown in this article or through electrical power analysis software, e.g. SKM, ETAP, or EasyPower. To determine the short-circuit current for SPDs connected at the secondary side of a transformer, simple calculations can be used.

Fuses or circuit-breakers, whether internal or external to the SPD, are required to obtain a short-circuit current rating and shall not hinder the performance attributes of the SPD. The short-circuit current rating of the SPD is required by standards to be located either on the SPD or in the accompanying installation instructions. The type and location of the SPD disconnector is also included in the installation instructions.

When performing the risk assessment, the engineer should obtain data from the manufacturer of the SPD whether the short-circuit current test was conducted with the MOVs being replaced with a copper block or if the MOV was installed during the test. SPDs tested with the MOV replaced with a copper block and an internal disconnector can lead to a safety hazard that requires an additional enclosure or protective measures to be considered in the final installation.

REFERENCES

- International Electrotechnical Commission (IEC). Low-voltage Surge Protective Devices – Part 12: Surge protective devices connected to low-voltage power distribution systems – Selection and application principles, IEC 61643-12. Geneva, Switzerland.

- Institute of Electrical and Electronic Engineers (IEEE). IEEE Guide for the Application of Surge-Protective Devices for Low-Voltage (1000 V or Less) AC Power Circuits, IEEE C62.72TM – 2007. NY, NY USA.

- International Electrotechnical Commission (IEC). Low-voltage Surge Protective Device – Part 11: Surge protective devices connected to low-voltage power systems – Requirements and test methods, IEC 61643-11. Geneva, Switzerland.

- Cole, B.R., Brown, K, McCurdy, P.S., Phipps, T.E., and Hotchkiss, R. The Short Circuit Current Ratings of Surge Protective Devices. 2006 IEEE Power Engineering Society Summer Conference. Available [on-line] at IEEE Explore.

- McKeown, D., Simple Methods for Calculating Short Circuit Current without a Computer, Retrieved 2012 August 10, Available [on-line] at http://www.geindustrial.com/publibrary/checkout/Short%20Circuit?TNR=White%20Papers|Short%20Circuit|generic.

- Underwriters Laboratories (UL). Standard for Safety, Surge Protective Devices, UL 1449, 3rd Edition. Northbrook, IL USA.

Bryan Cole is the president of Technology Research Council. He has more than 25 years experience in the design, development, application, and product safety of power quality equipment, aviation instrumentation, and various low-voltage distribution equipment. He is an IEEE member, a number of UL Standard Technical Panels, a member to the US National Committee to the IEC, and has assisted in the development of numerous national and international standards related to electrical power systems. Cole is a former US Marine, is a NARTE Certified Engineer, holds a Bachelors degree in electrical engineering, and an MBA with a focus in Technology Management.

Jim Tiesi is the Marketing Manager for Emerson Network Power Surge Protection. Tiesi has 20 years of experience in the design, development, application, and marketing of power quality equipment. He is active in various working groups for both the IEEE and NEMA, and is a member of the product development and Management Association. Tiesi holds a Bachelor of Science degree in electrical engineering and a master’s degree in Business Administration.