Protecting electrical systems within a facility is paramount to ensure equipment operation and longevity.

Bryan Cole, Technology Research Council, Nichols, New York, USA

Jim Tiesi, Emerson Network Power Surge Protection, Binghamton, New York, USA

Surge protective devices (SPDs) are utilized in numerous applications: commercial buildings, telecommunication shelters, industrial plants, and health care facilities. While each application has unique requirements, installing SPDs in health care facilities is complicated by the requirement to separate the electrical distribution among normal, essential, and emergency (i.e., critical and life safety) systems.

When one hears the term health care facility, the first thought is a hospital; however, health care facilities include a diverse group of structures that range from multicampus hospitals to a small doctor’s office located within a multiple occupancy building. Health care facilities include “buildings or portions of buildings in which medical, dental, psychiatric, nursing, obstetrical, or surgical care are provided.”[1] This includes hospitals, nursing homes, and various types of clinics and care facilities designed for diagnosis, treatment, and healing.

Because health care facilities are used to help people in a time of need, there are a number of safety requirements that have been established by various government agencies, associations, and/or organizations. For the electrical system of a health care facility, the standards of the National Fire Protection Association (NFPA) and the Institute of Electrical and Electronic Engineers (IEEE) are among the most prominent. The standards that have specific requirements for heath care systems are:

- National Electric Code, NFPA 70,

- Standard for Health Care Facilities, NFPA 99,

- Life Safety Code, NFPA 101,

- Standard for Emergency and Standby Power Systems, NFPA 110,

- IEEE Recommended Practice for Electric Systems in Health Care Facilities, IEEE 602

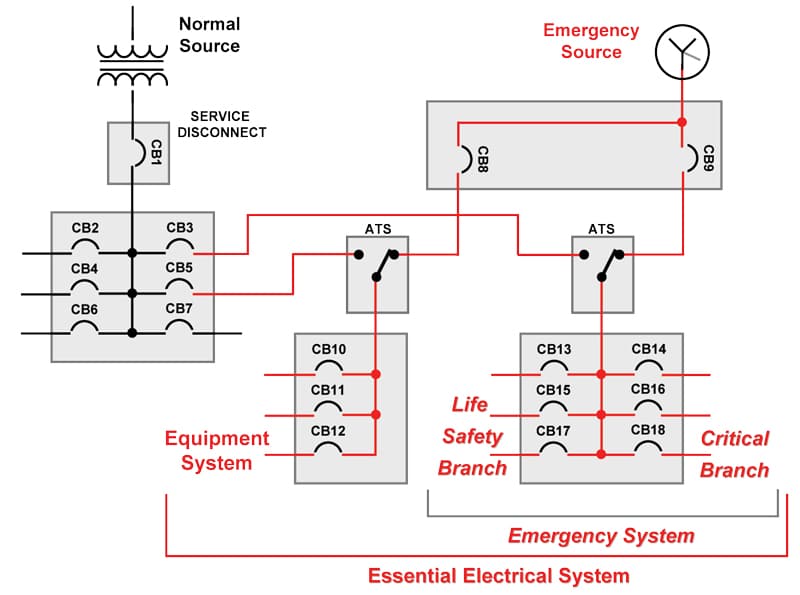

The National Electric Code (NEC) divides the electrical system of a health care facility into two parts: essential and non-essential (Figure 1). The non-essential electrical system includes systems that are deemed has having no effect on life or safety. Nonessential systems include accounting (e.g., patient billing), non-emergency lighting, and comfort heating, ventilation and air conditioning (HVAC) equipment. Information technology (IT) systems and other data processing equipment that are considered as non-essential may be connected to an uninterruptible power system (UPS) or an optional power source. Lighting, comfort HVAC, and other non-essential electrical systems may also be connected to alternate power sources, but are deemed as nonessential loads.

Essential electrical systems ensure the safety of the occupants (e.g., doctors, nurses, patients) and visitors. The essential electrical system is also divided into two systems: the equipment system and the emergency system. For example, central vacuum or compressor air systems for surgical areas, HVAC equipment for patient care areas, and stair pressurization systems are connected to the equipment system.[2]

The emergency system is composed of two subsystems: the life safety branch and the critical branch. The life safety branch includes equipment associated with the safety of patients and others within the heath care facility.[1] The life safety branch includes equipment such as those associated with egress lighting, fire alarms, emergency communications, and automatic doors.[2] Elevators installed in multiple level heath care facilities used to evacuate personnel and patients from the structure are also connected to the life safety branch.[2] The critical branch of the emergency power system includes those functions associated with illumination and patient care.[1] This includes areas of the health care facility such as operating rooms, postoperative rooms, areas for medical preparation and patient monitoring (e.g., nurses stations), and other areas associated with patient care.[2]

The essential electrical system (Figure 1) is required to be physically and electrically separated from the nonessential electrical system within the heath care facility except at the normal service (utility) source, at the emergency power source (e.g., generator), and specific switchgear and transfer switch equipment.[1] The essential electrical system must also be identified through distinctive markings.[1]

CONNECTION TO THE NORMAL & EMERGENCY POWER SYSTEM

Utilizing two separate power sources increases the probability that critical systems will be energized when needed, even in adverse conditions. Under normal conditions, the health care facility operates from the normal source, which is typically connected to utility power. The reliability of utility power depends on the geographical location within the United States and the number and severity of storms that occur in the area, as well as other unpredictable incidents (e.g., traffic accidents or wildlife accidents).

Under abnormal power conditions, health care facilities must operate from an emergency power source.[1] Emergency power sources are typically generators, but if approved by the authority having jurisdiction, it can also be a second, but separate utility source.[1] Regardless of the emergency power source, the essential electrical system must be configured such that electrical power can be transferred from the normal power source to the emergency power source(and in reverse when normal power is restored). The only approved type of equipment that can connect the essential electrical system or the emergency system to either the normal or emergency system is the automatic transfer switch (ATS).[1]

During the design of a health care facility, it is often asked, “should I use a three-wire or a four-wire automatic transfer switch to connect the essential loads to the normal and emergency power sources?” The answer depends on the system. If the facility operators are required to have, or want to have, ground fault protection installed on the emergency power source, then a four-wire ATS is required. If ground fault protection is not required on the emergency power source, then a three wire ATS can be used.

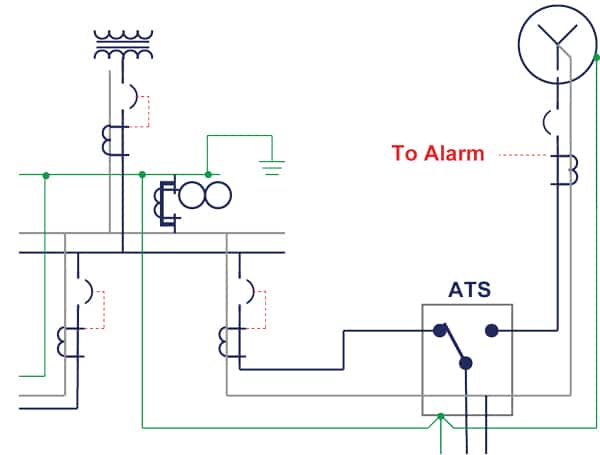

The interconnection of the normal and emergency power source utilizing a three-wire ATS is shown in Figure 2. In this example, the normal power source has a neutral-to-ground bond at the service entrance. At the ATS, the normal power source phase conductors are terminated at the terminals marked for normal source. The neutral conductor is terminated at the neutral bus bar, and the ground conductor is terminated to the ground bus in the ATS. At the ATS, the emergency power source phase conductors are terminated at the terminals marked for emergency source. The neutral conductor is terminated at the neutral bus bar, and the ground conductor is terminated to the ground bus in the ATS.

In stances when ground fault protection is not required on the emergency source, then the emergency power source is considered a non-separately derived system. In non-separately derived systems, the neutral conductor is common to both the normal and the emergency power source and is not disconnected by the switching mechanism of the ATS.

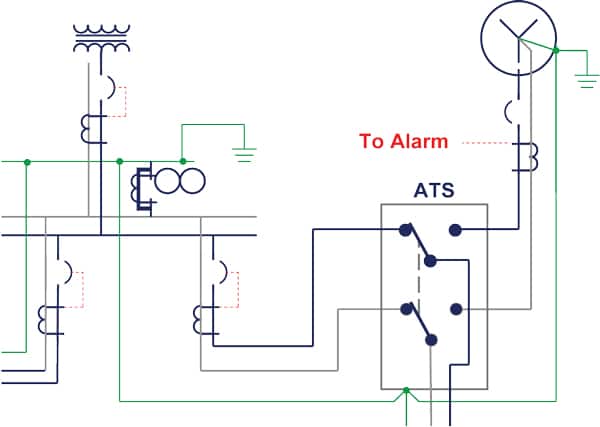

If facility operators are required to or elect to install ground fault protection on the emergency power source, then the interconnection of the normal and emergency power source must utilize a four-wire ATS (Figure 3). Failure to do so when ground fault protection is installed on the emergency power source will result in false tripping or improper tripping of the ground fault protection. These problems occur because current will be shared between the neutral-to-ground bond at the normal power source and the neutral-to-ground bond at the emergency power source [3, 4].

In the example shown in Figure 3, the normal source has a neutral-toground bond at the service entrance. At the ATS, the normal power source phase conductors and the neutral conductor are terminated at the terminals marked for normal source. The ground conductor is terminated to the ground bus in the ATS. At the ATS, the emergency power source phase conductors and the neutral conductor are terminated at the terminals marked for emergency source. The ground conductor is terminated to the ground bus in the ATS.

When ground fault protection is required or installed on the emergency source, then the emergency power source must be connected to measure the full ground fault current. To achieve this requirement, there must be a neutral-to-ground connection at the emergency power source and a separately designed system. In separately derived systems, the neutral conductor is not common to the normal and the emergency power source and is disconnected by the switching mechanism of the ATS.

For applications associated with life safety within a health care facility, the Standard for Health Care Facilities requires an analysis of the essential electrical system to adverse influences.[5] These influences include transient conditions caused by lightning and the switching of electrical components. To protect against lightning and switching surges, IEEE Recommended Practice for Electric Systems in Health Care Facilities recommends the installation of surge arrestors (surge protective devices).[6]

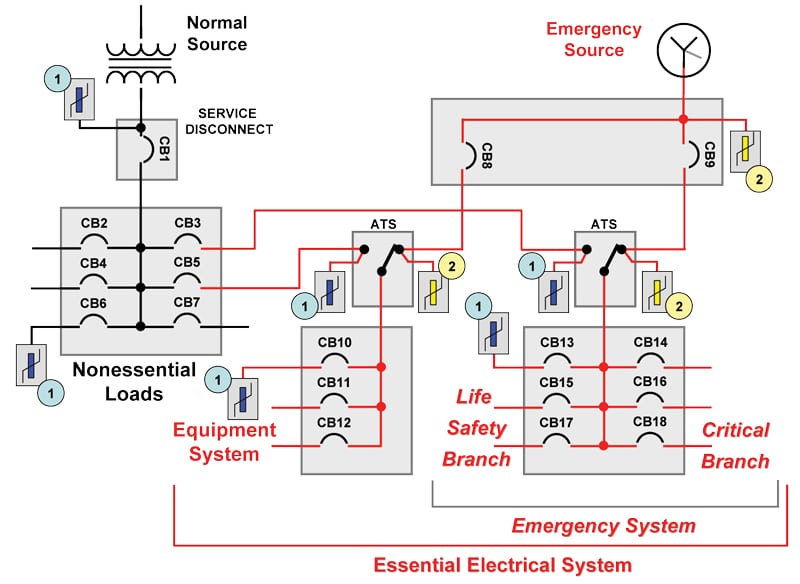

Properly protecting a facility from lightning and switching transient overvoltage conditions requires a staged or cascaded approach.[7] This approach has SPDs installed at the service entrance, all distribution panels, and end use equipment (Figure 4).

Connecting SPDs in a health care facility differs from connecting these devices into most commercial or industrial facilities because the essential and emergency electrical systems are physically isolated from the nonessential electrical system. Figure 5 illustrates the proper approach to employing SPDs within a health care facility. To protect the health care facility when it is connected to normal power, a Type 1 SPD is connected at the line-side of the service disconnect (CB1). Connection to the line-side is preferable to connecting at the loadside of the service disconnect. With this connection, transients are reduced before reaching the terminals or any electronic circuits (adjustable trip mechanisms). Type 2 SPDs are located at the non-essential distribution panel at circuit breaker CB6, the normal terminals of the equipment system ATS, the normal terminals of the emergency system ATS, the equipment system distribution panel circuit breaker CB10, and the emergency system distribution circuit breaker CB13. SPDs denoted as (1) are required for all systems were the emergency power source is contained within the same structure as the health care facility.

In most cases, the generators used to provide emergency power are located outside the health care facility itself. In those cases, it is important to apply SPDs, denoted as (2), to the line-side terminals of the emergency power switchgear, to the emergency power terminals of the equipment system ATS, and to the emergency power terminals of the emergency system ATS. The SPD installed on the line-side terminals of the emergency power switchgear must be a Type 1 SPD. The remaining SPDs should be Type 2 SPDs.

SPDs connected at the service entrance for normal power can have either line-to-neutral or line-to-ground modes of protection. The inclusion of all modes of protection (line-toground, line-to-neutral, neutral-toground) is not required there. The neutral-to-ground bond at the service entrance is sufficient. The connection can be made either at the meter can for small facilities, or at the service entrance switchgear for large facilities.

Similarly, if emergency power is provided with ground fault protection (Figure 3), then the SPD installed at the emergency source switchgear is not required to have all modes of protection. Conversely, if no ground fault protection is provided for the emergency power, all modes of protection are required because the neutral-to-ground bond is at the normal source and not in close enough proximity to the applied SPD. Downstream of the normal source and emergency source switchgear, SPDs with all modes of protection are required to ensure transient overvoltages do not damage equipment (Figure 6).

SPDs installed in a health care facility must be connected in accordance with the NEC and manufacturers recommendations. Article 285 in the NEC provides the requirements for connecting all surge protective devices (SPDs) rated 1,000 volts or less to the electrical distribution system of a facility. summary of the National Electric Code requirements[ 1] for installing an SPD onto the electrical power systems is as follows:

- Article 285.3 – SPDs shall not be used on ungrounded, impedance grounded, or corner grounded systems unless approved for use,

- Article 285.4 – Where used, SPDs shall be connected to each ungrounded conductor,

- Article 285.5 – SPDs shall be Listed,

- Article 285.6 – SPDs shall be marked with a short circuit current rating (SCCR), and shall not be installed at a point on the system where the available fault current exceeds the SCCR of the SPD,

- Article 285.11 – SPDs can be connected indoors or outdoors, and shall be inaccessible to unqualified persons,

- Article 285.12 – Conductors used to connect the SPD to the system shall be as short as possible,

- Article 285.23 – Type 1 SPDs are permitted to be installed on the supply side (line-side) or the load-side of the service disconnect,

- Article 285.24 – Type 2 SPDs are permitted to be installed on the loadside of the service entrance disconnect only. On separately derived systems, Type 2 SPDs must be connected on the load-side of the first overcurrent device,

- Article 285.26 – Conductors used to connect the SPD to the system shall be greater than 14 AWG copper, or 12 AWG aluminum, and

- Article 285.27 – SPDs shall be permitted to be connected between any two conductors of the system: grounded, ungrounded, or grounding conductors. Connection of the grounded and grounding conductors shall only be interconnected during a surge.

CONCLUSION

Health care facilities play a critical role in today’s society. During normal times, they are institutions that mend the sick, care for the elderly, and provide many preventative medical services that enhance our everyday lives. During times of emergencies, health care facilities can provide shelter against the elements and can afford critical care to local residents. To ensure that health care facilities have the electrical power needed to perform a wide range of services during many conditions, the electrical system is divided into various categories that make up non-essential systems and essential systems. Essential systems include the equipment system, the life safety branch and the critical branch.

Protecting electrical systems within a facility is paramount to ensure equipment operation and longevity. Essential electrical systems intended to provide critical care must have an assessment to determine their susceptibility to transient overvoltage conditions. To ensure that transient overvoltages do not damage equipment nor endanger patients and other occupants of a health care facility, the deployment of SPDs is recommended.

When installing SPDs into a health care facility, the following should be considered:

- SPDs should be installed in a cascaded methodology— service entrance, distribution panels, and end-use equipment.

- Individual SPDs should be installed on the non-essential system, the essential system, and the emergency system.

- Type 1 SPDs should be installed at the service entrance locations.

- Type 2 SPDs should be installed at all distribution locations.

- SPDs should be installed on the normal terminals of every automatic transfer switch (ATS).

- Emergency power sources installed external to the health care facility requires an SPD at the emergency power source, and at the emergency source terminals of every ATS.

- SPDs should be installed in accordance with the National Electric Code.

REFERENCES

[1] National Fire Protection Association, National Electric Code, NFPA 70-2008, Quincy, MA USA.

[2] Ode, M.C. (2004), “Nonmetallic Conduit for Essential Hospital Systems,” Electrical Contractor, Retrieved 2009 January. Available [online] http://www.ul.com/regulators/ode/0804.pdf.

[3] ASCO Power Technologies, Ground Fault Protection Considerations in Systems with Multiple Neutral-to-Ground Connections, Volume 2, Number 3, Florham Park, NJ.

[4] ASCO Power Technologies, Ground Fault Protection Considerations in Systems with Multiple Neutral-to-Ground Connections, Volume 2, Number 4, Florham Park, NJ.

[5] National Fire Protection Association. Standard for Health Care Facilities, NFPA 99-2005, Quincy, MA.

[6] Institute of Electrical and Electronic Engineers, IEEE Recommended Practice for Electric Systems in Health Care Facilities, IEEE Std. 602, Published 2007, Piscataway, NJ.

[7] Institute of Electrical and Electronic Engineers, IEEE Recommended Practice for Powering and Grounding Electronic Equipment, IEEE Emerald Book, IEEE-Std. 1100, Published 2005, Piscataway, NJ.

Bryan Cole is the President of Technology Research Council. Bryan has more than 20 years’ experience in the design, development, application, and product safety of power quality equipment, aviation instrumentation, and various types of low-voltage distribution equipment. He is an IEEE member and a member of a number of UL Standard Technical Panels. He serves on the U.S. National Committee to the International Electrotechnical Commission (IEC) and has assisted in the development of more than 30 national and international standards relating to electrical power systems. Bryan is a former U.S. Marine, is a NARTE-Certified Engineer, and holds a Bachelor’s degree in Electrical Engineering as well as an MBA with a focus on technology management.

Jim Tiesi is the Product Development Manager for Emerson Network Power Surge Protection. Jim has over 14 years of experience in the design, development, and application of power quality equipment. He is active in various working groups for both the IEEE and NEMA, and is a member of the Product Development and Management Association. Jim holds a Bachelor of Science degree in Electrical Engineering and an MBA.