According to military standards, passive electromagnetic LC filters of HEMP are recommended for use in all kinds of special-purpose electronic equipment. Experience gained by military specialists is usually employed when developing HEMP protection means and measures for civil equipment. Does it make sense to use extremely expensive and bulky HEMP filters for civil equipment? This article discusses the possibility to use cheap EMC filters for HEMP protection of civil equipment and provides test results of various types of such filters.

Special electromagnetic filters, consisting of different combinations of capacitors and inductors, are deemed to be one of the key means of protection that prevent the damage of electronic equipment from the electromagnetic pulse of high-altitude nuclear explosion (HEMP). Thus, the use of these filters is stipulated by numerous military and civil recommendations and standards, e.g. [1]. There are dozens of filters on the market manufactured by multiple companies, such as ETS-Lindgren, MPE, Meteolabor-EMP, European EMC Products Ltd., Captor Corp., LCR Electronics, API Technologies, Astrodyne TDI Corp., Fi-Coil, EMI Solutions Pvt. Ltd, RFI Corp., etc. When these filters are mounted on input terminals and supply circuits of sensitive electronic equipment, there is a possibility to protect the equipment both from HEMP and common electromagnetic interference under normal operating conditions. That is why extensive use of these filters could be viewed as a very useful technical aid, which improves the general noise-resistance of equipment until their price becomes evident.

Table 1: Weight and dimensions of HEMP filters from various manufacturers

| Weight, kg | Dimensions, mm | Manufacturer | Nominal Current, A | Type |

| 15 | 560 x 200 x 112 | European EMC Products | 16 | EEP16SPN |

| 27.2 | 940 x 229 x 127 | ETS-Lindgren | 5

10 |

LRX-2005-S2

LRX-2010-S2 |

| – | 720 x 90 x 130 | Holland Shielding Systems BV | 16 | 8080-2-16 |

| – | 762 x 229 x 140 | Captor Corp. | 10 | A-10543 |

| 10 | 420 x 200 x 120 | MPE Ltd. | 6

16 |

DS33330

DS33331 |

| – | 762 x 305 x 127 | LCR Electronics

(Astrodyne) |

20 | FH1960-2W

FH1970-2W |

| – | 750 x 150 x 110 | EMI Solutions (EMIS) | 10 | MF420-CF |

| – | 800 x 200 x 125 | Changzhou Noordin Etech. Co. | 16 | GPF271C-16 |

| 13.6 | 533 x 203 x 127 | Corcon

(TE Connectivity) |

10 | CDSUX20210A6 |

Even single-phase two-line filters (the simplest) designed for installation into a DC or single-phase AC supply circuit featuring 3–10A costs $1,500–2,500. Weight and dimensions of these filters (Table 1) worsen the situation.

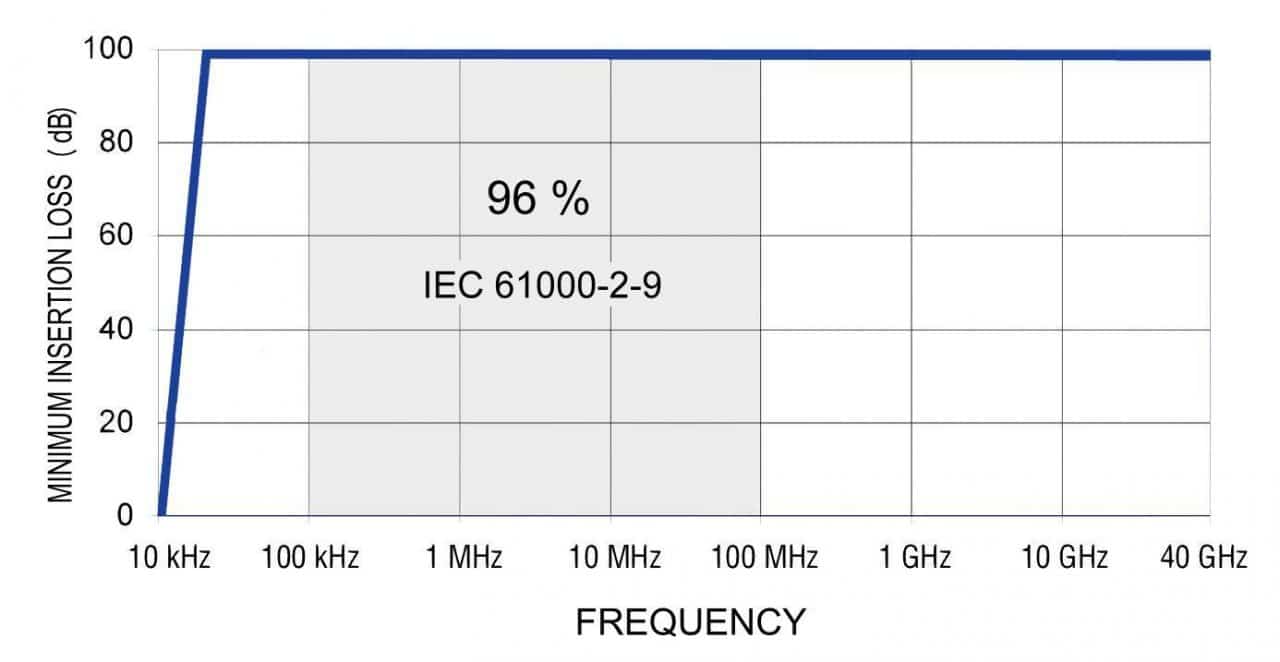

The first question that surfaces upon receiving the cost information is “What is special about them?” The answer can be found in the specifications of these filters (Figure 1).

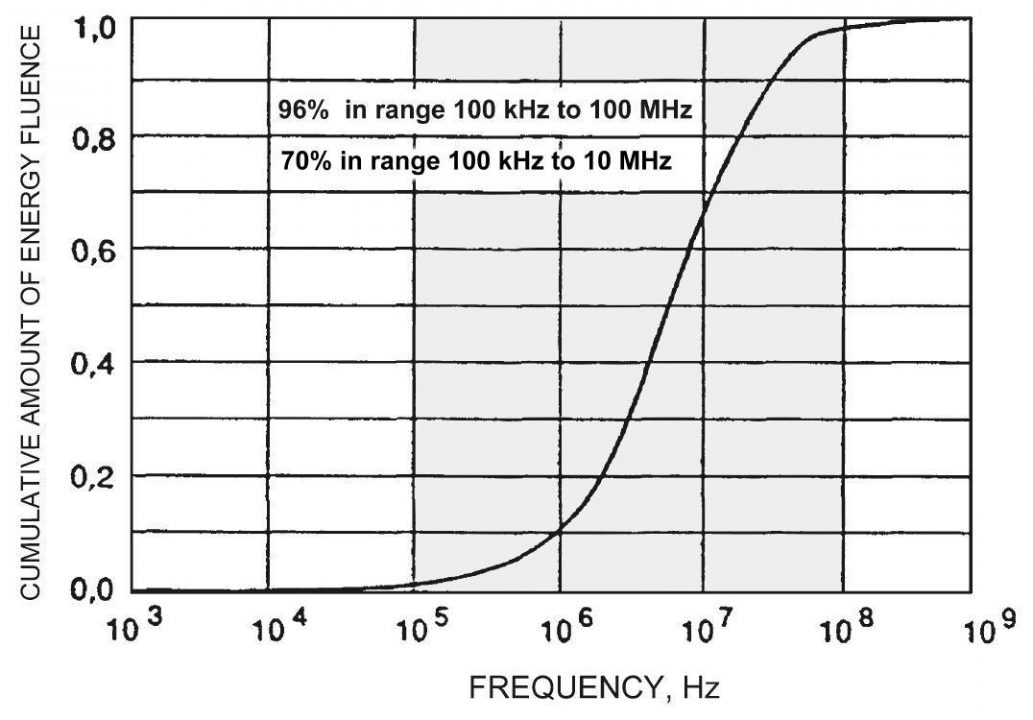

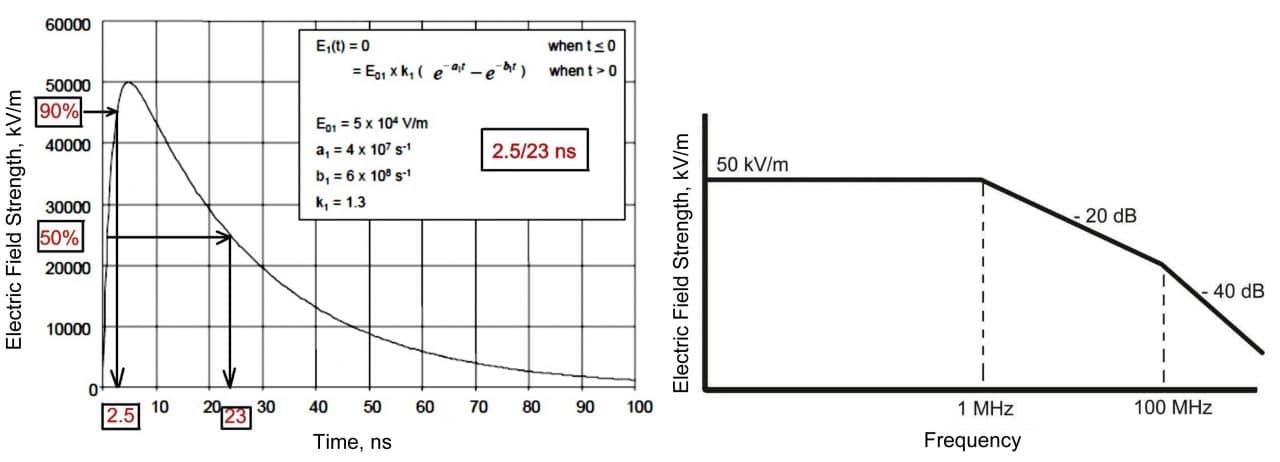

Figure 1 shows that the frequency range of these filters spans from dozens of kilohertz to as high as 40 GHz and the noise signal attenuation achievable within this range is 100 dB (i.e. 100,000 times in respect to amplitude!). Obviously, the broader the filter’s range, the more expensive it is. Additionally, it is really difficult to provide such noise attenuation in this frequency range (as promoted by ETS-Lindgren, Figure 1), which is possibly the reason for such expensive filters. But here is the question: Do we really need such a broad range for HEMP protection, if according to IEC 61000-2-9 [2] 96% of HEMP’s energy is emitted in 100 kHz–100 MHz range and 70% of the energy in 100 kHz–10 MHz range (Figure 2)?

Accordingly, if special HEMP filters are so expensive and their operating frequency range is much broader than that of HEMP, why don’t we take a closer look at cheaper filters designed to ensure electromagnetic compatibility (EMC) and improve noise resistance of electronic equipment from common electromagnetic interferences?

The range of such filters available on the market is very broad: there are both quite sophisticated inexpensive two-stage filters with fair specifications and very simple and cheap filters. These high-quality filters cost $20–40 only and some are even cheaper (manufactured in China). Moreover, these filters are 10 times smaller and lighter, which is also important, providing the necessity to install them in industrial control cabinets full of equipment.

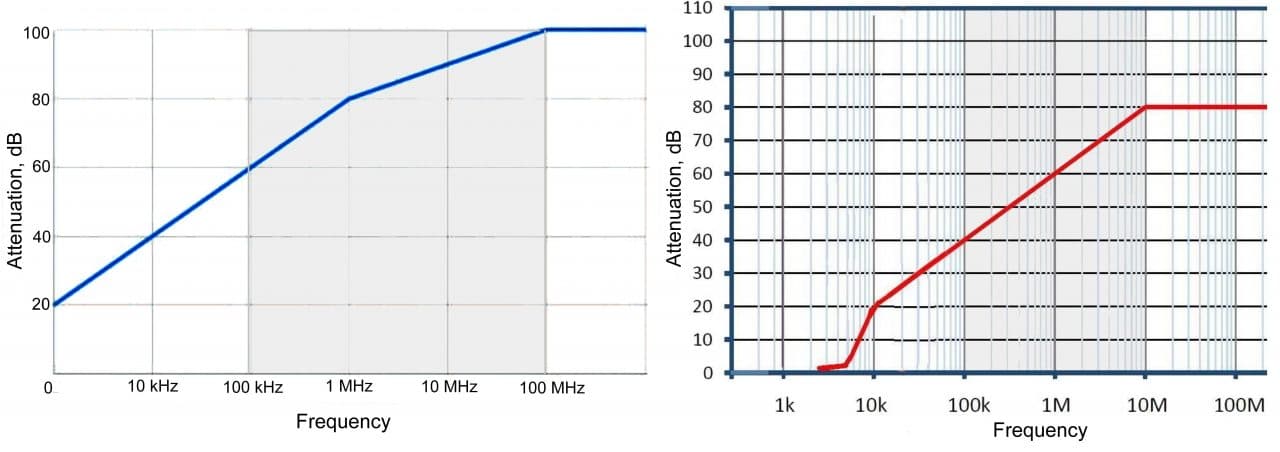

To what extent are cheap EMC filters worse than HEMP filters? Perhaps the answer to this question can be obtained after comparing the manufacturers’ specifications, which we shall investigate (Figures 4 and 5).

Consequently, the question is: Is the difference between HEMP filters and common high-quality two-stage EMC filters within 100 kHz–100 MHz range so significant to justify a 200-times higher price of HEMP filters? It is known that even small (40 dB) attenuation provided by EMC filters at the limits of the required range results in 100-fold noise amplitude reduction, i.e. to the level, corresponding to common interferences, which are always present in industrial and particularly power facilities. According to EMC standards, industrial electronic equipment should maintain its operability as affected by these interferences.

Nevertheless, it should be kept in mind that HEMP generates two absolutely different types of impact: damage of electronic devices caused by physical disruption of internal structure (destruction) and temporary failure caused by electromagnetic interference (upset). EMC filters do not provide protection from two kinds of these impacts. Moreover, they are not designed to work under high voltage and require protection from electric disruption under the high-voltage surges. Protection from physical damage caused by puncture of internal insulation upon the impact of high amplitude voltage pulse (surge) is provided by non-linear voltage suppressors, such as varistors or avalanche diodes (so-called transient voltage suppressors, TVS-diodes). This means that EMC filters protect only from temporary failures caused by high-frequency interference with restricted amplitude (upset). In other words, the role of EMC filters, compared to transient voltage suppressors, is secondary [3].

The above information makes it possible to conclude that it is illogical to use extremely expensive (also bulky and heavy) HEMP filters in civil equipment. But if we decide to continue with EMC filters, which of them should we choose? How can we choose the most efficient filters among the range offered on the market? The choice is complicated by the fact that various manufacturers use different methods and equipment to measure filter parameters and provide promotional or even erroneous information (discovered by the author) in their specifications. This necessitated conducting comparative trials of the best filter samples from the leading manufacturers under the same method and on the same equipment.

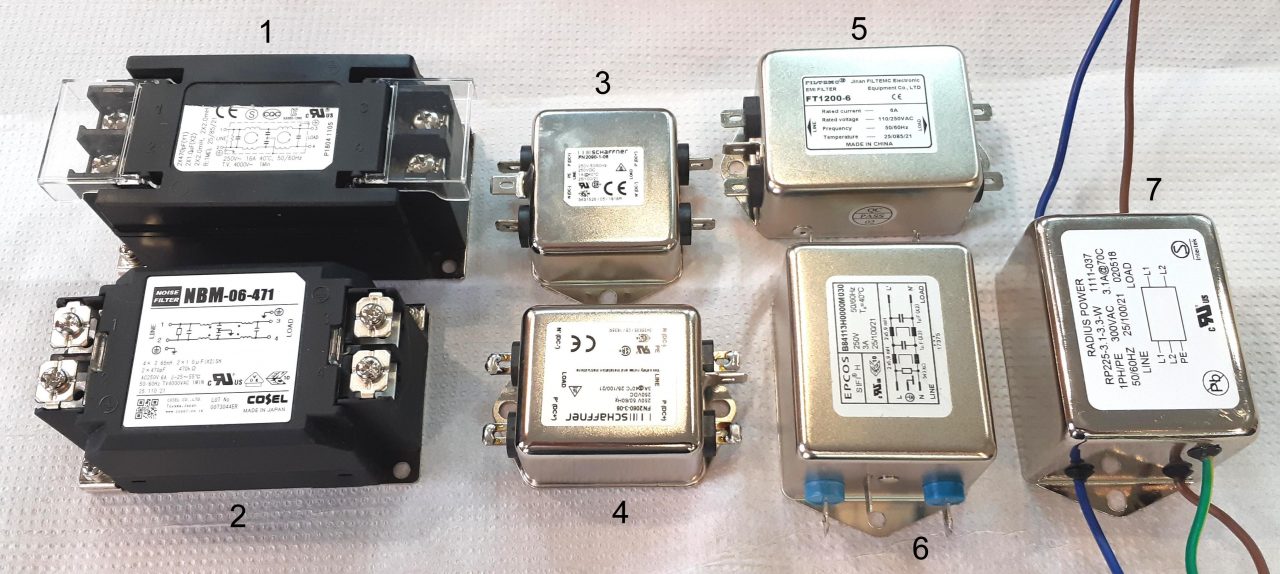

In order to conduct the trials, two-stage EMC filters were used, obtained by the author free of charge from various companies (Figure 6). Some manufacturers (e.g. Changzhou Pioneer Electronic Co.) did not agree to provide their filters for comparative trials for various reasons. Some companies manufacture filters for minimum current starting from 3A, while others start from 16A. Thus, the filters provided for testing significantly differed in terms of their current rating. Filters rated 3–5A at 230 VAC or 250 VDC nominal voltage are sufficient to be used in cabinets with microprocessor-based electronic equipment. Concurrently, it is not prohibited to use filters for 10–16A if they provide higher interference attenuation in the selected frequency range. For this reason, the nominal current rating (for which any of the filters is designed) was not considered during comparative trials of filters from various manufacturers:

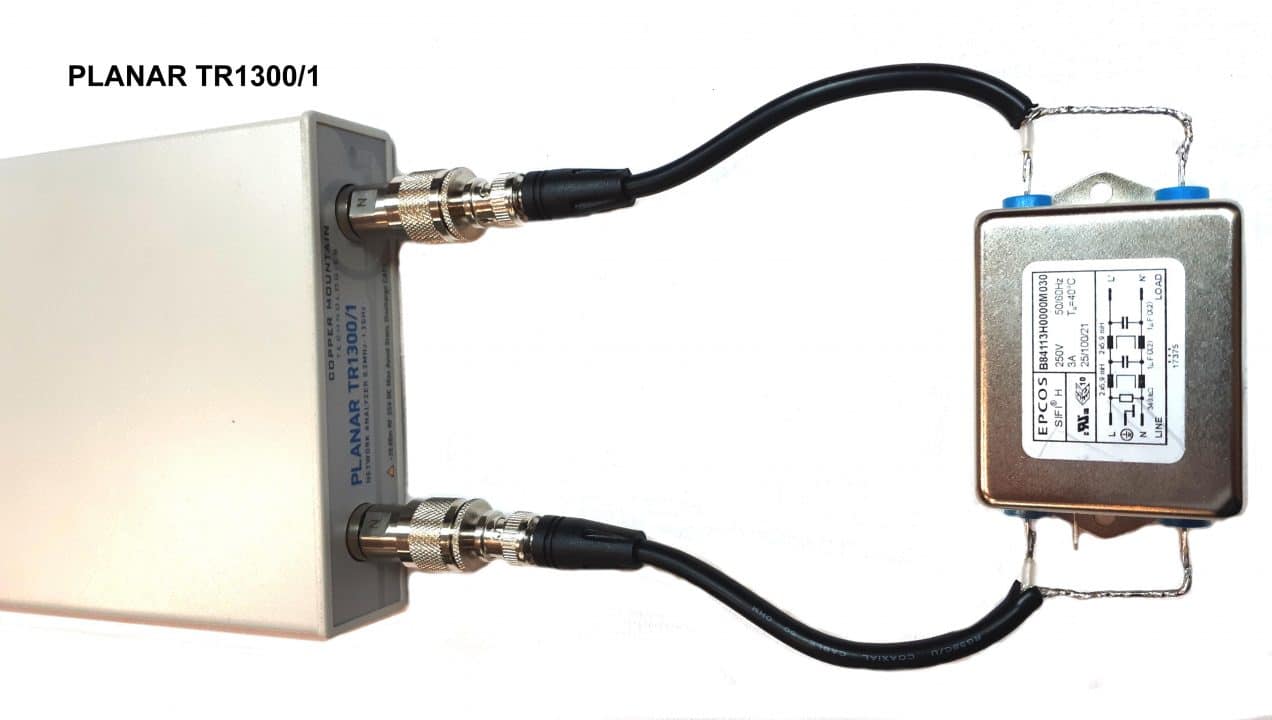

Attenuation measurements were taken by means of PLANAR TR1300/1 Vector Network Analyzer and its corresponding computer software (Figure 7).

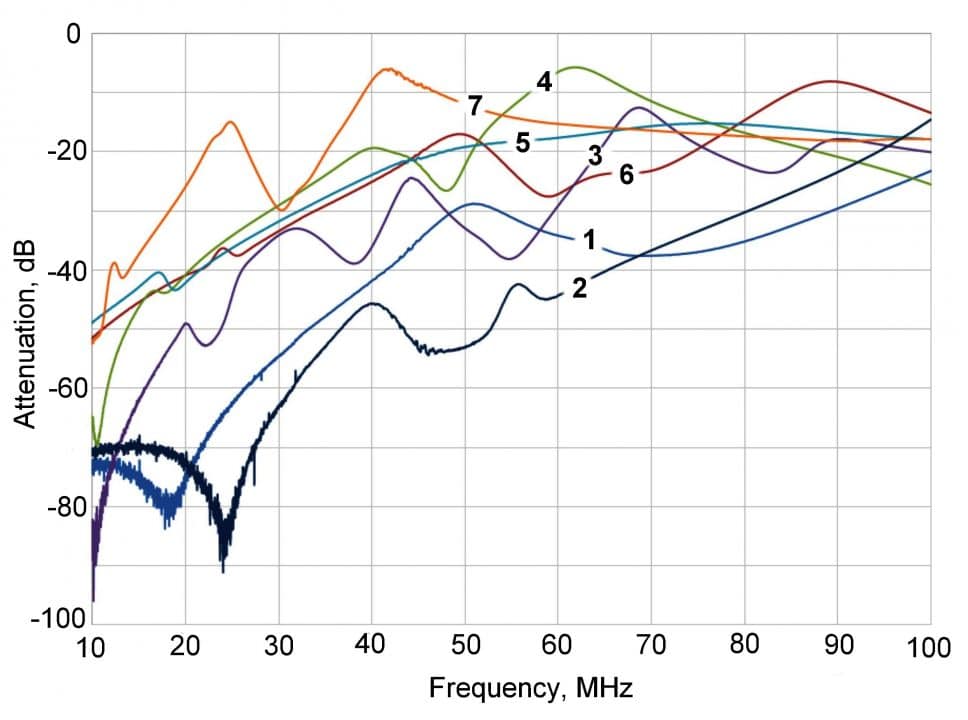

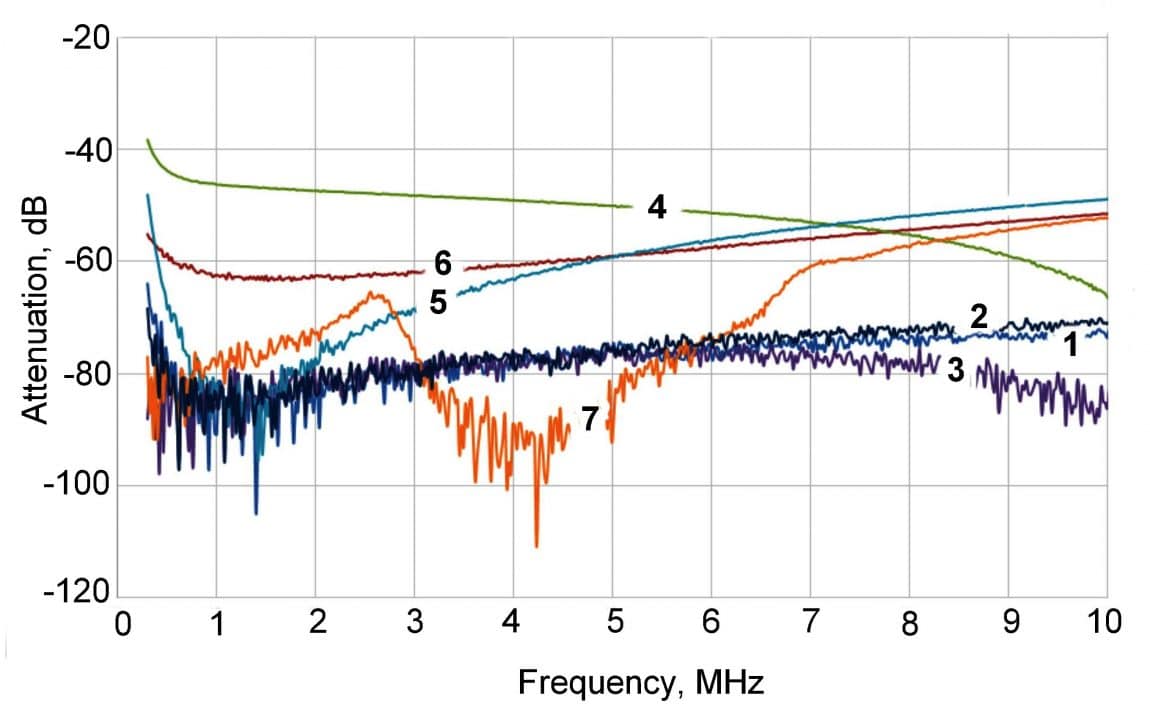

Attenuation values provided by different EMC filters are shown in Figure 8.

These results show that 62-MTB-060-4-21 type and NBM-06-471 type filters feature the best parameters in the required frequency range. Additionally, if we consider the significantly lower cost of a filter of type NBM-06-471, compared with the filter of 62-MTB-060-4-21 type, then there is generally only one winner in this competition.

Conclusion

Common EMC filters (inexpensive and small) available on the market are quite suitable for HEMP protection in civil industrial equipment. The best technical-economic characteristics are offered by NBM-06-471 filters, which are recommended for use.

References

[1] MIL-STD-188-125-1 High –Altitude Electromagnetic Pulse (HEMP) Protection for Ground Based C4I Facilities Performing Critical. Time-Urgent Mission. Part 1 Fixed Facilities, 2005.

[2] IEC 61000-2-9 Electromagnetic compatibility (EMC) – Part 2: Environment – Section 9: Description of HEMP environment – Radiated disturbance. Basic EMC publication, 1996.

[3] Gurevich V. Protecting Electrical Equipment. Good Practices for Preventing High Altitude Electromagnetic Pulse Impacts. – De Gruyter, Berlin, 2019, 386 p.