RF gasket selection must be a well-informed decision in the design process.

Gary Fenical, Laird Technologies, St. Louis, MD, USA

Advances in electronic components continue to occur at a rapid pace, and this ongoing rush means more and more wireless devices, increasing power levels, and higher frequencies. While consumers demand more advanced products with increased features and speed, engineers must work on the innovations that will fulfill that market demand. Many factors, such as increasing frequencies, miniaturization, heat, environmental issues, and more, must be weighed before working on enhancements to computers, digital cameras, video game handsets, RFID systems, laser readers, as well as countless other consumer and commercial devices.

To equip the industry with the tools necessary for the next wave of electronics devices, new electromagnetic interference (EMI) shielding capabilities, for one, are improving steadily. For example, the latest available products help companies by lowering costs, reducing waste, increasing airflow, and easing device installation in smaller spaces. Shielding products, in general, have experienced numerous noteworthy changes over the years. The uses, properties, and advantages of the new materials, as well as advanced EMI shielding product designs, have helped to create significant advances in the world of electronics.

This article explores some of the information required to make an intelligent selection of the appropriate shielding materials a bit clearer and easier. Detailed information on specific gaskets is not included because that information is readily available from manufacturers once the type of gasket(s) to be considered has been determined. Instead, the focus is on the key steps that will aid the design engineer to an initial choice for consideration. These considerations are not in any specific order. What may be the most important criterion in one situation may be farther down the list in another There are a myriad of shielding products to choose from. (Figure 1). The reader needs to evaluate each particular application and to categorize the list based upon each situation.

TEN IMPORTANT RF SHIELDING SELECTION CONSIDERATIONS

- Operating Frequency: This is a critical consideration, and the designer must take into account RF frequency, distance, and harmonics.

- Attenuation Performance: This is impacted by the installation and mounting of the shielding, the conductivity of surrounding materials, and the physical fit of the shielding gasket.

- Materials Compatibility/Corrosion: It is important to choose a shielding gasket that is closely compatible with the metal of the conducting surface on which it is mounted.

- Environmental Sealing: Electrically Conductive Elastomer (ECE) is the only single product that combines both RF shielding and environmental properties.

- Compression Load or Force: As pressure is applied to the shielding gasket, it can change shape resulting in inferior performance. Careful selection of the correct size, thickness, shape, and material is required.

- Fastening/Mounting Methods: Many types of mountings are available including pressure sensitive adhesive (PSA), clip-on, slot mounted, riveted, soldered, welded, fitted die-cut profiles, snap-in, and more (Figure 2).

- Nuclear, Biological or Chemical Hazards: Clearly these are important factors in military applications, but are also a consideration in medical or food-service facilities and anywhere equipment may be involved in harsh wash-down, chemical, or processing applications.

- Compression: Compression range and compression set are factors that must be considered to ensure effective performance and gasket life.

- Space/Weight Considerations: These can be especially pressing factors in designing portable, hand-held devices or in aerospace applications.

- Recyclability: Products must meet the current RoHS requirements of the European Union as well as environmental requirements imposed by manufacturers.

EXAMINING THE VITAL CRITERIA

Not all of the considerations below will pertain in every situation; however, when they do apply, they can be very important.

Corrosion

Although the importance of galvanic compatibility has received considerable attention, it is a vital consideration that merits reiteration. Corrosion of RF shielding gaskets is one of the major failure mechanisms. Corrosion is a major problem in electronic systems because the corrosive salts produced during electrochemical reactions can act as insulators that degrade shielding or function as semiconductors that create unwanted RF signals through nonlinear mixing—i.e., the “Rusty Bolt Problem.”

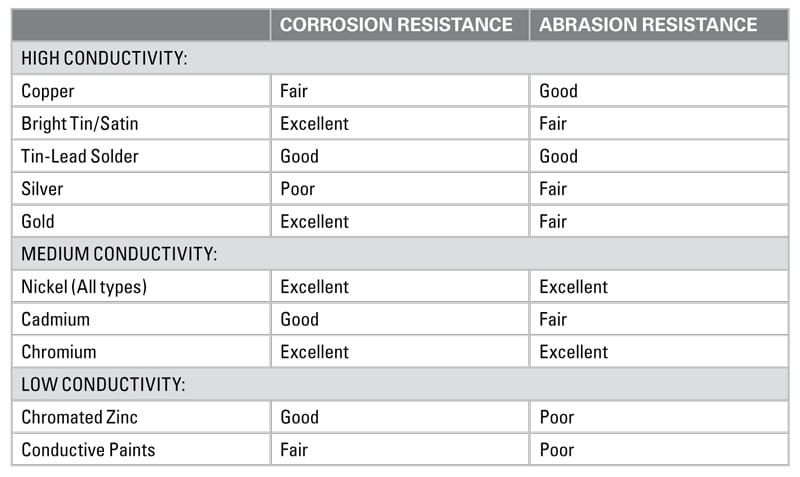

Three major contributors to the problem are exposed surface area, materials dissimilarity, and the presence of an electrolyte—usually moisture. Stamped or formed solid metal gaskets have minimum surface area. The surface is nonporous, and the gaskets seal out moisture. Also, metal is generally not hygroscopic. These characteristics act to reduce but not to eliminate corrosion. Wire mesh gaskets, on the other hand, have increased surface area; thus, the corrosion properties are not quite as good as for the solid metal fingers. Still, either gasket type can be easily plated with other metals to minimize galvanic corrosion couples. The information that follows shows the considerations taken into account when specifying plating (Table 1).

Elastomer gaskets tend to be self-sealing, a characteristic which reduces moisture infiltration beyond the edges. This characteristic frequently limits the corrosion to the outer edges of the gasket contact region. The availability of many different conductive fillers allows for minimization of the corrosion problem. Some available fillers including:

- Carbon(C)

- Inert aluminum (IA)

- Nickel-coated graphite(Ni/C)

- Silver-coated glass (Ag/G)

- Silver-coated nickel (Ag/Ni)

- Silver-coated aluminum(Ag/Al)

- Silver-coated copper (Ag/Cu)

- Silver (Ag)

The generally accepted criterion for galvanic compatibility is MILSTD- 1250. Very briefly, this standard does not permit galvanic couples that exceed 0.25 volts. Most commercial applications in a controlled environment will allow up to 0.5 to 0.6 volts. One of the worst galvanic couples is that of silver against aluminum, which can range up to 0.85 volts. In such applications where large contact voltages occur, the more reactive material will be destroyed. To prevent this problem, the gasket material, the mating surfaces, or both, will need to be plated with a material that is compatible.

Sliding Contact Surfaces

Solid metal flat spring-type products can be used in either a shear application or under direct compression. In a shear application, it is possible to design a seam in which the solid metal gasket compression forces will be aligned parallel with the mating surfaces of an enclosure. The knife-edge arrangement is an example of such a seam. There is a distinct advantage to parallel force alignment because it eliminates the requirement for multiple, evenly-spaced fasteners to maintain the gasket compression. In any case, with a spring finger configuration, there will be shear forces developed because the shield and gasket surfaces will slide across each other. Since the BeCu surface is very hard compared with the oxidation and/or corrosion films, the gasket and mating surfaces form a self-cleaning contact.

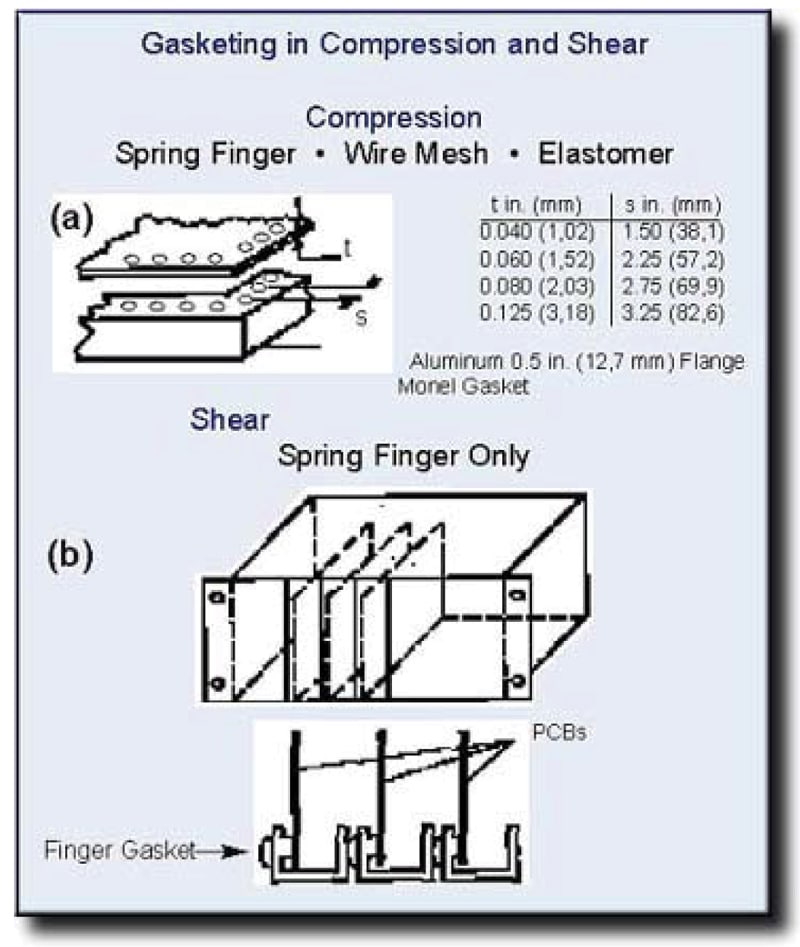

Wire mesh or conductive elastomers cannot be used in shear. They can only be used in direct compression. When they are compressed, no shear forces are developed and no sliding action occurs so they are not self-cleaning. At points of high contact pressure, the wire mesh and elastomer gaskets create a gas tight Figure 2. Mounting methods. seal that prevents corrosion directly under the contact although there may be corrosion adjacent to the contact. As long as the gasketed joint is not disturbed, the shielding effectiveness will remain high. If the mating surfaces are moved, the gasket will generally not realign its corrosion-free contact points with those of the mating surfaces, and the shielding will be degraded.

Fabric-Over-Foam (FoF) gaskets are also useable in shear configuration. Tests have shown that FoF gaskets used within their design range perform as good as new after tens of thousands wiping cycles. Similarly to solid metal gaskets, FoF gaskets can be self-cleaning in wiping applications although they are not as hard and have less compression force.

Shear vs. Compression

When gaskets are installed under a flat cover panel, in a compression configuration, properly spaced screws or clamps must be used to preserve the shielding effectiveness of the enclosure. Fastener spacing is determined by the stiffness of the cover material and the compression force of the gasket materials. If the gasket material has a large variation in conductivity vs. pressure, such as carbon or metal filled elastomers, then the screws must be installed using a torque wrench, or the mating surfaces must have positive mechanical stops to provide uniform compression and to minimize the variation in shielding effectiveness. In fact, except for gaskets that can be fully compressed, such as solid knitted material, positive mechanical stops should be the norm.

As an alternative, shear gaskets, such as a beryllium copper (BeCu), stainless steel finger, or FoF gaskets, can be used in a flange-and-pan or channel-and-pan arrangement (knifeedge) and will completely eliminate the need for fasteners to preserve the shielding effectiveness of the enclosure. This arrangement can be used for PCB or equipment panels; cabinet panels or doors; and for large-scale building panels, doors, and windows (Figure 3).

RF Impedance

In DC or low frequency grounding or bonding applications, conductivity across the seam is the most important parameter. Conversely, at the higher RF frequencies, the gasket inductance becomes the most important parameter. Self-inductance is related to the geometry of the material in the following ways:

- a factor of 10x decreases the inductance by approximately

10%. - Increasing the width of a rectangular conductor by a

factor of 10x decreases the inductance by approximately

30%. - Decreasing the length of a rectangular conductor by

a factor of 10x decreases the inductance by approximately

93%.

Clearly, the conductor with the largest width-to-length ratio will provide the lowest inductance.

BeCu has the highest conductivity of any material that can be converted into a spring—approximately 150 percent greater than phosphor bronze, the next best material. In a BeCu conductor, the conductivity (which is important at lower frequencies) is proportional to the cross-sectional area. Solid fingers have greater cross-sectional area and hence higher conductivity. In addition, the finger shape during use (width >> length) has the characteristics of an interconnecting ground plane with a large contact surface area rather than a wire. The inductance of a ground plane is three to four orders of magnitude less than that of a wire.

The conductivity/inductance relationships, which are both material and shape dependent, result in the gaskets being ranked from best to worst as follows. For low frequencies (from 50 kHz to 10 MHz), BeCu spring finger, BeCu wire mesh, Monel/SnCuFe wire mesh, and silver-filled elastomer. At high frequencies (over 100 MHz): BeCu spring finger, silver filled elastomer, BeCu wire mesh, and Monel/SnCuFe wire mesh.

Gasket Breakage

All electronic components, including RF gaskets, can suffer damage and/or breakage that can limit their useful lives. Since RF gasket materials are generally used on movable surfaces where they become exposed to direct physical contact, designers should consider some form of inherent protection for the materials.

Solid metal BeCu RF finger gaskets are very rugged with a yield/breakage strength of approximately 190,000 lbs./sq. in.—1310 MPa (MegaPascals). Unfortunately, the cross-sectional area is between 0.001 sq. in. (0.65 mm2) and 0.002 sq. in. (1.29 mm2) which reduces the tensile breakage force to about 190 to 380 pounds (86 to 173 kg) for a typical finger. Flexure life is in excess of 50,000 cycles, and any premature breakage of the material is generally the result of a deficient installation design. During use, solid metal BeCu gaskets will not stretch or tear and this characteristic prevents misalignment that might otherwise result in breakage. Even if the material breaks, the pieces are large compared with BeCu or Monel/SnCuFe wire mesh; and conductive elastomer fragments and the pieces do not splinter.

Wire mesh gaskets made from BeCu retain the breaking strength and flexure life of the solid metal gaskets, but the wire strand cross sectional area is on the order of 0.00001 sq in. (0,0065 mm2) to 0.00002 sq. in.(0.0129 mm2). Consequently, the tensile breakage strength per strand is reduced to 1 lb. to 2 lb. (0.45 kg to 0.91 kg). The lower breakage strength results in increased wire strand breakage, but can be partially offset by the limited compression range of the mesh gaskets. Monel/SnCuFe materials have similar breakage problems, but have the additional disadvantages of higher compression force, compression set, and lower shielding effectiveness. Also, they are lower in cost, a factor that offsets many negative properties if the desired performance can be achieved.

Although elastomer gaskets give the appearance of a breakage-free configuration, the application of tensile and compression forces results in the release of the gaskets’ conductive particles located at the surface. The number of particles released is increased over longer periods of time by material aging, a process in which conductive particles are being sloughed off from the surface of the binder material. In any given application, possible damage arising from the selection and location of gasket material merits careful consideration. Broken fingers, tiny broken wire strands, and conductive flakes and particles can be distributed throughout the electronics through natural and/or forced air cooling systems.

CONCLUSION

In 25 years in the RF shielding industry, this author has never seen a properly manufactured RF gasket fail. Invariably, the failure arises from misuse, improper joint design (e.g., trying to put a gasket where a gasket was never meant to go), or some other poor RF gasket selection choice. With today’s short design cycles and timeto- market, it is imperative that well-informed decisions are the cornerstone of the entire design cycle, including RF gasket selection. Remember as well, the trained Field Application Engineers provided by the RF gasket manufacturer, who can provide invaluable advice on these all-important design decisions.

ABOUT THE AUTHOR

Gary Fenical is the Senior EMC Engineer at Laird Technologies and is the author of many articles on EMC requirements for medical devices, Mutual Recognition Agreements, and guidelines to meet the essential requirements of the EMC Directive. Gary is past chairman of the SAE AE-4, E3 Committee on EMC. Gary can be reached at (570) 424-8510 or gary.fenical@lairdtech.com.