By Markus Holzbrecher

1. Background

1.1. Chip bead ferrites

Chip bead ferrites are inductive surface mount devices (SMDs) used for filtering undesired high frequency signal distortions in printed board assemblies. They are manufactured using a multilayer screen printing process. Optimised for as high as possible losses, these components consist of a nickel-zinc-ferrite body with a very fine embedded silver coil with a thickness of just a few micrometres. This structure makes the conventional SMD ferrite beads vulnerable to current spikes above their maximum rated load, resulting in degenerative or even immediate destruction of the component in some cases.

1.2. Application

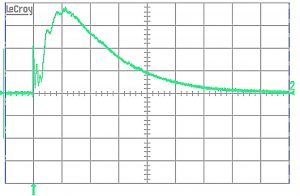

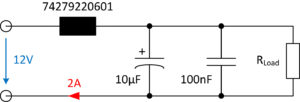

A typical chip bead ferrite application is shown in Figure 1. The multilayer ferrite is used as a longitudinal filter near the input of a circuit. Due to the low charging resistance of the capacitor, a very high pulse current flows for a short time at switch-on. This pulse current temporarily loads the SMD ferrite with a current that can reach many times the component’s maximum rated level.

In this example, a multilayer ferrite designated as Multilayer Power Suppression Bead (MPSB) has a rated impedance of 600 Ω for a maximum permissible current load of 2.1 A. The current surge in this constellation reaches a peak value of approx. 19 A and has a pulse length of 0.8 ms before declining to the circuit’s rated current.

Figure 1: Application showing current peak at switch-on (5 A/DIV, 100 µs/DIV)

In general, a SMD ferrite’s maximum rated current also defines the component’s maximum current amplitude for any given temporary load. However, multilayer ferrites are now available that cater for current surges above their maximum continuous current as rated in their data sheets. Examples of these new components are examined in more detail below.

1.3. Testing method

Current peaks occur frequently in real life applications, for example at switch-on of switch mode power supplies and electric motors. Windscreen wiper motors in vehicles are a well known example for recurrent current pulses. But discharge lamp ballasts can also produce high current peaks when the light is switched on. The input capacitor in a switch mode power supply can produce a particular high current peak, which the upstream EMC filter needs to withstand. In this context, pulses are understood as temporary current peaks above the circuit’s rated DC current level limited to a time span of less than 8 ms.

In search of a common standard for measuring the pulse load capacity of SMD ferrites, an appropriate approach was found in the definition of the melting integral for fuses. According to this standard, a pulse of 8 ms duration is applied to the fuse to “give the current time” to heat the fuse to determine its I²t value. If the fuse withstands a given current pulse, the current is increased and this is repeated until the fuse fails. In this process, pauses of 10 seconds are inserted between pulses to give the component the necessary time to regenerate (cool down).

Würth Elektronik eiSos has developed an adapted test routine for multilayer ferrites based on this fuse testing standard. Using the same 8 ms pulse length, current pulses with increasing strength are applied to the multilayer ferrite up to their destruction. The components are subjected to incrementally increasing pulse currents starting from 1 A.

A rectangle as shown in Figure 2 was selected as pulse shape for all tests as this loads the component with the highest possible energy for a given pulse length although this will only very rarely be applicable in real-life situations.

2. Pulse Load Capacity Analysis

Other than with fuses, multilayer SMD ferrites do not to lend themselves to specifying a generally applicable formula allowing conclusions to be drawn for various current peak values and different pulse lengths by calculating the melt integral. Rather, data sheet values are determined empirically and rely on extended test series with varying parameters.

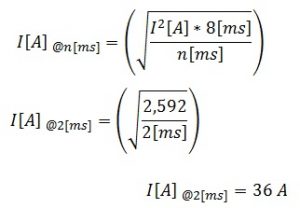

The following example serves to confirm that the melt integral is unsuitable the multilayer ferrites (using the Würth WE-MPSB ferrite 742 792 206 01 with Z = 600 Ω, IR = 2.1 A, and RDC,typ = 43 mΩ). This component has a maximum peak current load capability of 18 A at a pulse length of 8 ms, which produces an I²t value of 2.592 A²ms (18 A @ 8 ms (5 sec pause, 24 °C) I²t = 2.592 A²s).

The following result is obtained when calculating the current for a pulse length of 2 ms based on the I²t value for 8 ms:

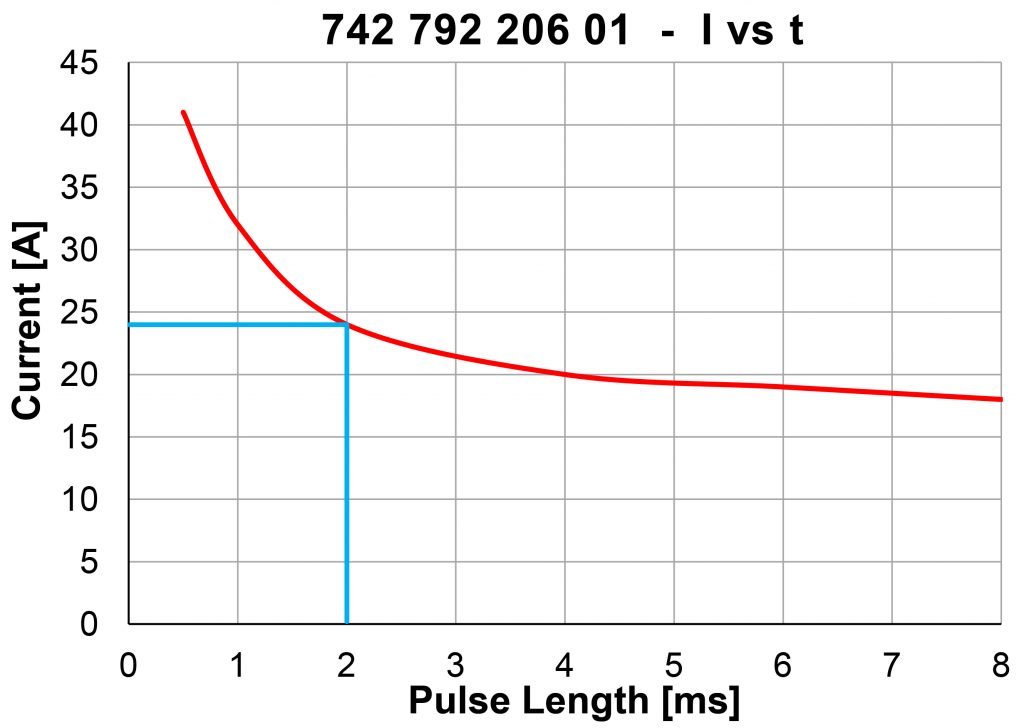

However, the data sheet value is specified as max. 24 A as shown in Figure 3. The calculated I²t value differs significantly from the measured value. This shows that it is not appropriate to apply the known calculation method for the melt integral I²t to a multilayer ferrite.

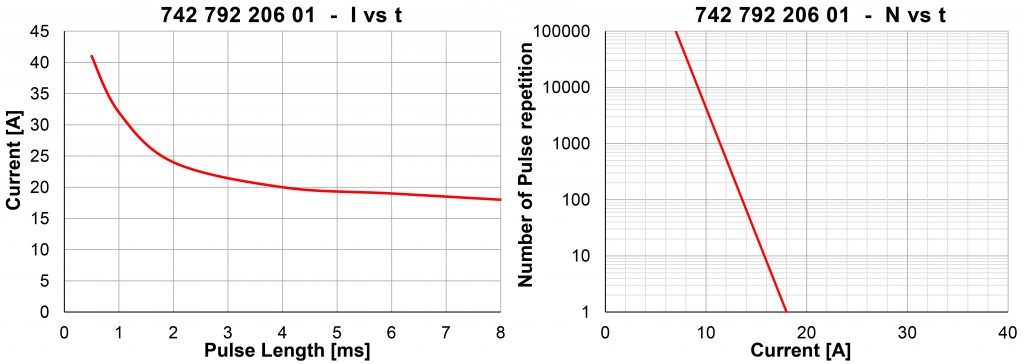

Figure 3: Specified peak current load capability

2.1. Optimising the multilayer structure

Due to their silver layers with thicknesses of only 8 to 20 µm, multilayer ferrites are not inherently designed for high pulse currents. Würth has developed a new design with a combination of high current tolerance, up to 75% smaller RDC and as high as possible impedance over their complete frequency range. Depending on the desired impedance and peak current level, the design is varied for each individual component type.

2.2. Current pulse tolerance relationships

Figure 4 shows the new ferrite bead’s current pulse tolerance behaviour in more detail using the 742 792 206 01 bead type as an example. The current vs. pulse length curve on the left side shows the maximum permitted peak current for pulse lengths ranging from 0.5 ms to 8 ms. Each ferrite bead type has an individual curve of this kind and these curves are only applicable for singular current pulses. The right graph

shows the maximum permitted pulse current for repeated current pulses. A maximum pulse length of 8 ms was selected to determine these values.

2.3. Influencing factors

The factors influencing the ferrite beads’ behavior are:

- The pulse length, with standard test values ranging from 0.5 ms to 8 ms. The longer the pulse, the lower the maximum pulse load capability.

- The number of pulses, which was varied from 10 to 100,000 pulses in the tests (see Figure 4). The maximum permissible current pulse load drops as the pulse frequency increases.

- The temperature should be noted as third reducing influencing factor: As the temperature rises, RDC increases, which results in a further reduction of the maximum permissible current pulse load.

Each of these interlinked factors is affected by the dependency on the pause length between individual pulses. In order to carry out an analysis of the linked system with a smaller pause time, all measurements need to be repeated while varying the influencing factors, temperature [T], pulse repetitions [n] and pulse length [t].

2.4. New and previous ferrite bead series comparison

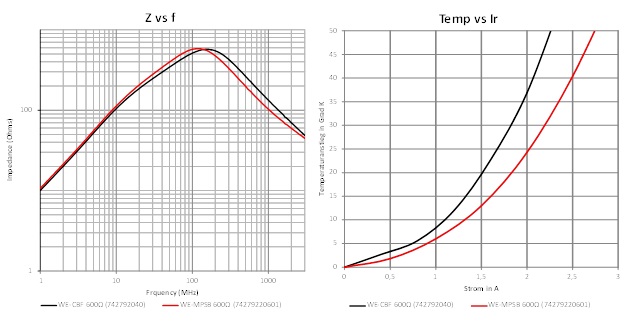

When developing their new ferrite bead series, Würth followed the objective to achieve impedance levels comparable with their previous series with additional tolerance to pulse current loads. Using the example of the 600 Ω models in size 0805 as shown in Figure 5, the new series is shown to exhibit almost the same impedance along with a higher rated current pulse tolerance due to its lower resistance.

Figure 5: Impedance and rated current load capability of the 600 Ω WE-CBF and WE-MPSB bead ferrites

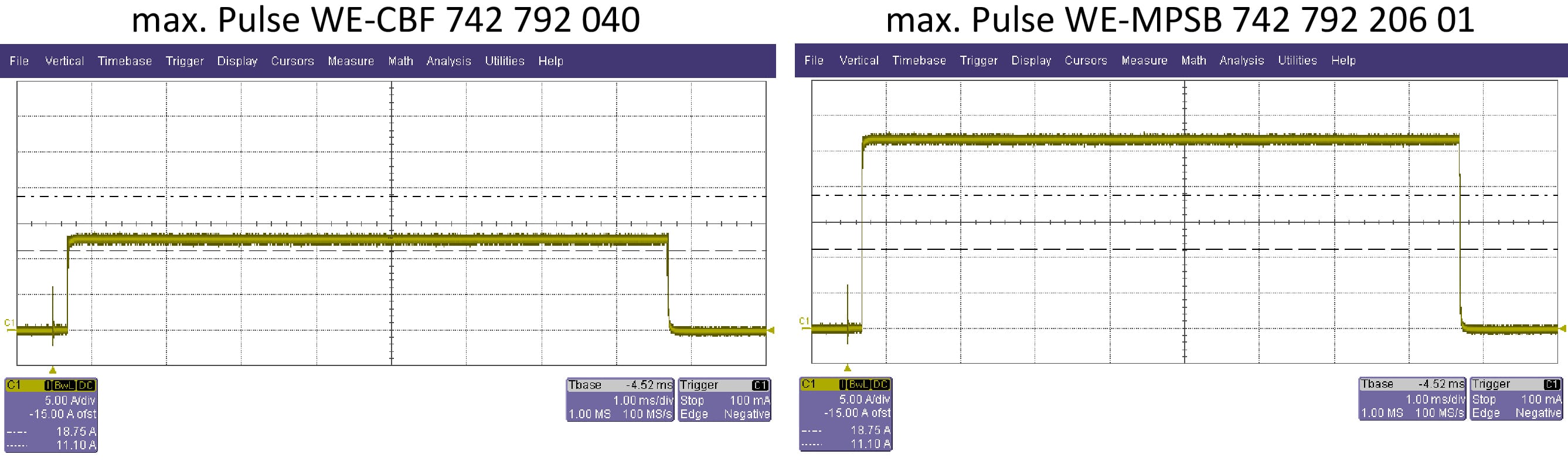

The new ferrite beads exhibit a significantly higher pulse load capability than the equivalent previous types. Figure 6 shows the maximum pulse level of the older 600 Ω type on the left and the maximum pulse level of the comparable newer 600 Ω model on the right. Moreover, Würth is now able to specify the pulse load capability of SMD ferrites manufactured in the multilayer screen printing process.

Figure 6: Comparison of the different pulse load capability of the WE-CBF and WE-MPSB series bead ferrites

3. Conclusion

Specific chip bead ferrite components can now cater to the requirements of circuits that load multilayer ferrites with temporary peak currents exceeding their rated maximum continuous current. The components’ multilayer structures are optimised to enable a higher current load capability by lowering the structure’s inherent resistance. The maximum pulse load capabilities of the new multilayer ferrites were determined using empirical measurements as calculations using a formula for the behaviour of fuses proved inappropriate.

Author’s biography:

Markus Holzbrecher, born 1983, graduated from Leipzig University of Applied Sciences with a diploma degree in Electrical Engineering. Since 2011, he has been responsible for the product area of EMC components for PCB assembly at Würth Elektronik eiSos.