Performance and reliability of a shielding system is essential in times of emergency.

Wayne D. Martin, ETS-Lindgren, Glendale Heights, Illinois, USA

The most cursory assessment of news and events around the globe during this first decade of the Twenty-First Century leads to the inescapable conclusion that we live in perilous times. Around the globe, political, ethnic and religious strife results in violence. This paper does not discuss the capabilities or readiness of the United States military or that of its allies, nor does it focus on developing effective standards for first-responder communications both inside and outside challenging environments such as skyscrapers and tunnels. (See accompanying short article titled “Measurements to Support Improved Wireless Communication for Emergency Responders” at the very bottom of this page.) Instead, it lays out a more modern scenario that could be just as devastating to our economy and way of life as an all-out nuclear war and details steps that the military, local government, utilities or industry itself can take to ward off such a catastrophe.

THE THREAT

Confidence remains high that the United States military can and will defend America from a missile attack originating outside the country. The nation has an extensive missile defense program, a legacy of the Cold War era; and the government has had many years to prepare for whatever the future may hold, as well as plenty of doctrines for guidance. Terrorism is the Twenty-First century version of the last century’s world wars. Terrorists have seized the moment and have staged attacks in many First World countries. Recall 9/11, the Madrid train bombings, the London subway attack, and the attempt on Glasgow Airport. Terrorizing nations or people has been achieved though conventional weaponry such as explosives, or in the case of 9/11, by turning our own technology against us. In today’s world, weapons of mass destruction (WMD), so called “dirty bombs”, radio frequency weapons (RFW), and intentional electromagnetic interference (IEMI) devices can generate localized electromagnetic pulse surges to disrupt everyday services.

Critical infrastructure facilities are a vital part of everyday life. These facilities include electric power facilities, oil refineries, water treatment plants, banking systems, pipelines, transportation systems, emergency facilities, and communications facilities. Most critical infrastructure facilities depend upon electrical and electronic systems to function. These systems can be susceptible to a little known, yet significant and growing threat, the radio frequency weapons mentioned above. RFWs have already been used to defeat security systems, to disable police communications, to induce fires, and to disrupt banking computers. Many of these devices are small, suitcase-sized or slightly larger devices that could be smuggled into the country the same way drugs and other contraband penetrate our borders and become available on the black market. These devices in the hands of a terrorist are capable of inflicting extreme damage and may be capable of generating a localized intentional EMI disturbance at any location.

Looking back to that fateful day in September 2001 and realizing the magnificent job local, state, and federal officials in New York did in managing the World Trade Center crisis makes one feel proud. Imagine what might have occurred if the perpetrators of that vicious attack had included in their suicide mission the detonation of an electromagnetic pulse device that could disrupt communications of the police, fire, and medical teams responding to the emergency. Surely, many more lives and properties would have been lost. The sudden inability of the mayor and other city government officials to mobilize resources during such a chaotic event could be catastrophic. At present, homeland security, some local law enforcement agencies, and border patrol resources have been stretched extremely thin. Unfortunately, they are not credited for deterring potential attacks as much as they will be remembered for the one they did not.

AN EMP ATTACK DEFINED

The detonation of a nuclear device in or above the Earth’s atmosphere produces an intense, time-varying electromagnetic field (electromagnetic pulse or EMP). The EMP environment produced by an exo-atmospheric event is caused by the sudden entrance of energy (chiefly gamma rays) into the atmosphere. When such an event takes place above 30 km, it is defined as a HEMP (high altitude electromagnetic pulse) effect and can affect a vast area. Detonation of a weapon at lower altitudes will produce an electromagnetic pulse that may be less intense, but will still be strong enough to induce fields that can cause critical systems in a smaller more localized area to malfunction because of circuit damage (Figure 1). Another form of attack, intentional electromagnetic interference (IEMI), has been defined as the “intentional malicious generation of electromagnetic energy introducing noise or signals into electric and electronic systems, thus disrupting, confusing, or damaging these systems for terrorist or criminal purposes.” Nature’s contribution, lightning EMP (LEMP), like HEMP and other forms of EMP, involves a brief but intense electromagnetic disturbance in the atmosphere and thus presents another potential threat to the operation of electronic systems.

SYSTEM SURVIVABILITY

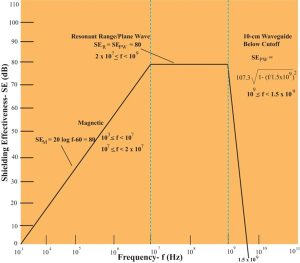

The U.S. military bears the responsibility of establishing a HEMP-hardened electrical parameter barrier for mission critical military operations that will ensure system survivability during a HEMP event. Creating an electromagnetic barrier that will prevent or limit HEMP or localized EMP fields or conducted transients from entering the shielded area is primary. The shield and all points of entry (POE) must be treated properly to maintain shield integrity. They must be hardened to provide at least 80 dB attenuation in the plane wave field from 10 MHz to 1.5 GHz and magnetic attenuation of 2 dB at 1 kHz rising to 80 dB at 10 MHz in accordance with MIL-STD-125-1 and -2 (Figure 2).

Obviously, the HEMP shield and all POE protective devices are hardness critical items (HCIs). All devices installed as special protective measures are also HCIs. Collectively, the HCIs constitute the HEMP protective systems. Items such as shielded vestibules with interlocked doors, waveguide honeycomb vents, various pipe penetrations, power and signal line filters with surge protection (electronic surge arrestors or ESAs), and fiber optic penetrations are all HCIs—individually or as part of an assembly.

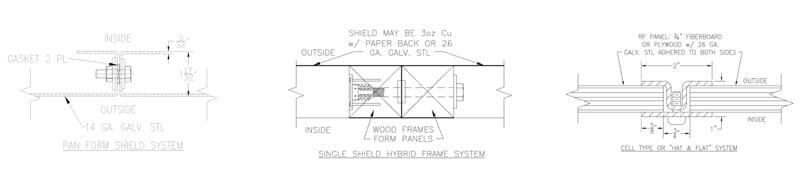

Generally, HEMP facilities are specified as welded systems by the military to be installed during the initial building stage. Warranties of 20 or 30 years are common, i.e., the same as for the parent building. Smaller facilities, upgrades or retrofits may involve other forms of shielding, particularly modular shielded panels. Industry standard modular shielding systems are available in single-shield copper or steel, double-layer steel cell type, or steel pan form enclosures and are easily installed in existing facilities needing HEMP or EMP protection.

AN ALTERNATIVE SOLUTION

One alternative to relying entirely on the military and federal government protection and intervention involves a “Plan B” solution—i.e., the cost-effective shielding of high value assets. Specific areas within a facility containing critical high value hardware, software, or other equipment should be hardened to the effects of IEMI or other deleterious electromagnetic conditions.

Shielding Protection

Present shielding technology can be used to protect existing Regional Emergency Management Control Centers (REMCCs) or the combined regular and emergency communications facilities from the effects of EMP. Single- or double-layer steel enclosures, steel pan form designs, and single-layer copper systems are available in modular designs that will exceed the HEMP/IEMI performance requirements of the military standard. These modular systems can be installed within an existing facility to meet the dimension and operational needs of a particular entity. Even the aesthetic expectations of customers can be met with a choice of interior/exterior finishes (Figure 3).

Still, shielding the dispatch or command/control room is only the first part of forestalling EMP damage to vital communications. Vital communications equipment is, of necessity, deployed throughout the community when emergency strikes. The equipment of first-responders could be damaged or rendered totally inoperable during an initial surge. Fire houses, police precincts, hospitals, fire trucks, police cars, and ambulances are all vulnerable to electromagnetic pulse.

To protect the overall functioning of an emergency system, the vital equipment linking first responders to the command system must be shielded as well. Today’s shielding industry produces small copper enclosures fitted with shock mounts that can be installed in all mobile field units. These shielded boxes will exceed the MIL-STD-188-125 performance requirement and will protect field radios from electromagnetic pulse (Figure 4).

As standard operating procedure (SOP) as defined by the user, members of mobile units at the fire or police precinct could exchange the emergency walkie-talkie radios in their vehicles with freshly charged units at the fire house or police precinct every 24 hours, or as necessary. Similarly, ambulance crews could have an alternate exchange point at a local hospital or other appropriate location. Those radios in need of recharging could be placed in a secure shielded enclosure with a battery charging system. Since radios are a high cost item, the recharging stations should be in tamper-proof security containers (Figure 5).

SYSTEM RELIABILITY

The Selection Process

Several critical aspects of the proposed system merit careful consideration. These include maintenance, installation timing and cost, life cycle parameters, and the system’s adaptability vis-à-vis a number of physical requirements. As noted above, typical shielding system construction choices include welded steel rooms or buildings, modular systems made of galvanized steel or copper-clad panels, and modular pan form designed systems for retrofitting or for establishing shielding within an existing facility. Pin-pointing any possible weak links during the design stage of a shielding system helps to assure reliable performance after procurement. Enclosures without seams or penetration may be ideal, but they are impractical. Still, to achieve the most reliable shielding system, it is always good policy to minimize penetrations and seams. This premise underlies a useful management philosophy that can be applied throughout the shielding system selection process. Consider these key factors affecting modular shielding system performance—material characteristics, quality of seams and penetrations, door performance, accessory performance, and the quantity of seams and penetrations.

Material Characteristics and Seam Quality

While the goal of achieving a cost-effective shielding solution may begin with a consideration of the attenuation characteristics of the shielding material, once a decision regarding all-welded steel vs. modular steel/copper panels has been made, the next crucial consideration is seam quality. While fewer seams would logically mean less potential for degradation, it is seam quality that is absolutely vital. An analysis of shielding alternatives indicates that some seaming techniques require fewer seams per shielding surface area. For example, “Pan Form” construction requires only one seam per joint. In contrast, the standard “Double Electrically Isolated” (DEI) construction requires two seams per joint. Standard modular plywood (cell-type) construction requires four seams per joint. Generally, two layers of shielding are used simply because seam quality makes it difficult to achieve the shielding objective with just one layer of shielding. Still, with high quality seaming, one layer should be sufficient (Figure 6).

Shielded Doors

Once a material and construction type has been chosen, shielded doors become the most critical component in the system. Doors are one of the few active components subject to daily wear and tear. To preserve the integrity of a shielded enclosure, doors must include a durable means for making repeatable seals around their entire perimeter. Shielded door performance should provide a safety factor of up to 20 dB both initially and after a reasonable number of cycles for all requirements up to 100 dB at 10 GHz. Achieving a 20-dB factor of safety at 1 GHz is no problem. The industry standard RF door most suitable for modular cell or pan form enclosures is the Single Knife Edge (SKE) door (Figure 7). As a safety factor, MIL-STD-188-125-1 requires a vestibule to maintain shield integrity. The SKE door can be set up for semi-automatic operation with a door interlock system that prevents both doors from being opened at the same time.

Accessories

Accessories are needed to transmit power and signals, HVAC, liquids, or gases into or out of a shielded environment. While accessories have an important impact on total system performance, their performance can be controlled by following proven techniques and by applying the appropriate design principles. Necessary penetrations that do not compromise shielding effectiveness can be achieved by using a combination of power line filtering combined with ESA and MOV (metal oxide varistor) protection or with waveguide below cut off and fiber optic concepts (Figure 8). Signal line interfaces, penetrating the shield, should use a fiber optic system for optimum EMP security.

Performance Testing

As a minimum at the time of acceptance, all shielding systems should be tested to confirm shielding performance in accordance with MIL-STD-188-125-1 and -2. Shielding effectiveness testing is generally a field test at the highest frequency of usage. The shield and all points of entry must be hardened to provide at least 80 dB of attenuation in the plane wave field from 10 MHz to 1.5 GHz and magnetic attenuation of 2 dB at 1 kHz, rising to 80 dB at 10 MHz. Overtime, all shielding systems will degrade with normal wear and tear. Retesting should be an annual scheduled requirement—a fail-safe measure that will detect any problems before system failure occurs and thus assures ongoing EMP protection.

Maintenance

One of the critical problems with the use of a shielding system is the lack of any clear-cut understanding of exactly who is responsible for maintaining the integrity of the system. At too many facilities, there is an ongoing power struggle to shift shield maintenance responsibility from the facilities to operations department and vice versa. Unfortunately, without clearly defined responsibility for preventative maintenance, shield integrity will diminish rapidly. Even when a problem is finally noticed, there is a tendency to resort to untested, “band-aid” or quick fix solutions. These solutions may satisfy the primary objective of meeting shielding requirements temporarily, but may not provide an adequate factor of safety to assure long-term reliability.

SUMMARY

Absolute performance and reliability of a shielding system is essential in times of emergency. The key to obtaining a good shielding system is an understanding that seams, doors, and other penetrations are the critical elements that must function as a whole to create an effective shielding system. It is the design of the shielding system and the quality of the installation that will determine its long-term reliability. In many cases, single-shield, “Pan Form” modular steel, double-shield galvanized steel cell-type panels, or a lightweight 12 or 24 ounce copper system can provide a reliable, cost-effective solution for EMP applications.

There are many shielding vendors in the market today. To protect a shielded system investment, look for a full service, turn-key designer, manufacturer, installer and tester of shielding systems with years of experience in the military and government arena and a strong background in the EMP field. Insist on seeing test reports from previous installations that document the vendor’s ability to provide a reliable shielding system.

ACKNOWLEDGEMENT

The author would like to thank Dr. William A. Radasky of Metatech Corporation for his invaluable review of this article.

END NOTES

Those who wish to read further on this topic might wish to consult:

1. Report of the Commission to Assess the Threat to the United States from Electromagnetic Pulse Attack: Executive Report, 2004.

2. Presidential Decision Directive/NSC-63, May 22, 1998.

REFERENCES

1. MIL-STD-2169B – High-Altitude Electromagnetic Pulse (HEMP) Environment (U)

2. MIL-STD-188-125-1- DOD Interface Standard – High Altitude Electromagnetic Pulse (HEMP) Protection for Ground-Based C4I Facilities Performing Critical, Time-Urgent Missions – Part 1 – Fixed Facilities ( 17 July, 1998 )

3. MIL-STD-188-125-2- DOD Interface Standard – High Altitude Electromagnetic Pulse (HEMP) Protection for Ground-Based C4I Facilities Performing Critical, Time-Urgent Missions – Part 1 – Transportable Systems ( 3 March, 1999 )

4. MIL-HDBK-423 Military Handbook – High Altitude Electromagnetic Pulse (HEMP) Protection for Fixed and Transportable Ground-based C4I Facilities Vol. 1 – Fixed Facilities ( 15 May1993 )

5. William E. Curran and Wayne D. Martin, “Shielding for HEMP/TEMPEST Requirements” Lindgren RF Enclosures, Inc. Addison, IL, ITEM Annual Guide 1988.

6. “Commission to Assess the Threat to the United States from Electromagnetic Pulse (EMP) Attack – Statement Before the House Armed Services Committee,” July 10, 2008

7. “The Threat of Radio Frequency Weapons to Critical Infrastructure Facilities” – TSWG & DETO Publications, August 2005.

ABOUT THE AUTHOR

Wayne D. Martin retired as a Chief Radioman from the U.S. Navy in 1984 having gained 20 years’ experience working in HEMP and TEMPEST environments. Following his time in the Navy, he joined the RCA Service Company as a visual TEMPEST inspector/instructor and later joined Contel Federal Systems (a government contractor) and worked as a TEMPEST engineer. In 1987, he joined Lindgren RF Enclosures (now ETS-Lindgren) in Glendale Heights, IL. Since joining the company, Mr. Martin has continued to lend his expertise to the company’s RF shielding systems for government and commercial industries requiring protection from critical EMP and IEMI. As the Government Sales Manager and Facilities Security Officer, he also assists ETS-Lindgren’s sales, R&D, manufacturing, and installation departments in providing solutions to general EMI and RFI issues. He is currently at work on an article on specific shielding solutions for HEMP. The author may be contacted by phone at 630-307-7200 or via email at wayne.martin@ets-lindgren.com.

Measurements to Support Improved Wireless Communication for Emergency Responders

Dr. Kate A. Remley

NIST RF Fields Group 818.02

Boulder, CO

When emergency responders enter large structures (such as apartment and office buildings, sports stadiums, stores, malls, hotels, convention centers, warehouses), radio communication to other responders on the outside is often impaired. Wireless communication from within large buildings and other structures can be complicated by several factors, including the strong attenuation of radio signals caused by losses in the building materials, scattering from structural features (multipath), and the waveguiding effects of corridors and tunnels.

The National Institute of Standards and Technology (NIST) is involved in a multi-year project to investigate wireless communications problems faced by emergency responders (firefighters, police, and medical personnel) in disaster situations involving large building structures. The work, funded by the Justice Department’s Community Oriented Police Services (COPS) program through the NIST Office of Law Enforcement Standards, has grown out of communications problems such as those encountered during the September 11, 2001, collapse of the World Trade Center in New York. Emergency personnel outside the buildings could not communicate with those inside.

The work has involved collecting a large body of open-literature data of quantities used to assess wireless communication channels. To provide statistics on signal level and variability in representative environments, NIST researchers measured the received signal strength outside the various structures while a transmitter was carried throughout the interior. The researchers also collected data on the level of reflectivity (multipath) a signal encounters as it travels from within the structure to the outside.

Because lives may be at stake in emergency response scenarios, a higher standard for reliability of service must be applied compared to those that might be deemed adequate for commercial applications. As a result, some specifications must either be modified or newly developed. The experiments were carried out at emergency responder frequencies to gather germane and useful data for those developing and assessing new technologies and creating standardized test methods within the context of the unique needs of the emergency response environment.

This work placed NIST researchers in some interesting non-laboratory environments, including buildings schedule for implosion,[1-3 ]oil refineries and tunnels,[4-5] several large public buildings,[4] and, in related work, automotive manufacturing facilities.[6]

N.B.—These documents may be downloaded from the NIST website at: http://www.boulder.nist.gov/div818/81802/MetrologyForWirelessSys/ under the heading “Wireless System Measurements for Industry and the Public Safety Sector.”

REFERENCES

[1] C.L. Holloway, G. Koepke, D. Camell, K.A. Remley, D.F. Williams, S.A. Schima, S. Canales, D.T. Tamura, “Propagation and Detection of Radio Signals Before, During, and After the Implosion of a 13-Story Apartment Building,” Natl. Inst. Stand. Technol. Note 1540, May 2005.

[2] C.L. Holloway, G. Koepke, D. Camell, K.A. Remley, D.F. Williams, S.A. Schima, S. Canales, D.T. Tamura, “Propagation and Detection of Radio Signals Before, During, and After the Implosion of a Large Sports Stadium (Veterans’ Stadium in Philadelphia),” Natl. Inst. Stand. Technol. Note 1541, October 2005.

[3] C.L. Holloway, G. Koepke, D. Camell, K.A. Remley, S.A. Schima, M. McKinley, R.T. Johnk, “Propagation and Detection of Radio Signals Before, During, and After the Implosion of a Large Convention Center,” Natl. Inst. Stand. Technol. Note 1542, June 2006.

[4] C.L. Holloway, W.F. Young, G. Koepke, K.A. Remley, D. Camell, Y. Becquet, “Attenuation of Radio Wave Signals Coupled Into Twelve Large Building Structures,” Natl. Inst. Stand. Technol. Note 1545, Apr. 2008.

[5] K.A. Remley, G. Koepke, C.L. Holloway, C. Grosvenor, D. Camell, J. Ladbury, D. Novotny, W.F. Young, G. Hough, M.D. McKinley, Y. Becquet, J. Korsnes, “Measurements to Support Broadband Modulated-Signal Radio Transmissions for the Public-Safety Sector,” Natl. Inst. Stand. Technol. Note 1546, Apr. 2008.

[6] K.A. Remley, G. Koepke, C. Grosvenor, R.T. Johnk, J. Ladbury, D. Camell, J. Coder, “NIST Tests of the Wireless Environment in Automobile Manufacturing Facilities,” Natl. Inst. Stand. Technol. Note 1550, Oct. 2008.