Servo motors and variable frequency drives are wide-spread in the industry. Industrial automation cannot be imagined without these motors. This article deals with certain EMI-related issues inherent to these motors, specifically high-frequency drive signals.

Background

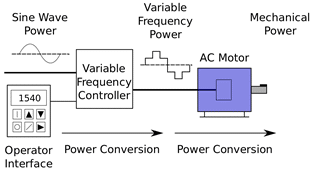

Servo motors and VFD are typically comprised of two parts – the motor itself and a controller (also called “amplifier,” “servo pack” or “inverter”) which drives the motor and is connected to it by cable. Controller receives power from AC mains. Servo motors have a feedback circuit that allows it to maintain specific position with high accuracy. This also means that servo motors work even when they are not moving. Variable frequency drives (VFD) work in a different way – their speed is controlled by the frequency of the drive signal. What is common between these two different types of drives is that both are driven by pulse-width modulated (PWM) signal. Figure 1 depicts block diagram of a typical VFD arrangement. AC mains power enters variable frequency controller which converts it into pulsed signal driving the motor. Servo motors (Figure 2) add feedback position control. A typical manufacturing and robotic tool may have as little as one and as many as 20 of such drives.

There are plenty of issues associated with VFD and servo motors – we will be focusing only on some of them – reader can simply look up on search engine for VFD, bearings, overvoltage and EMI to see the entire scope of problems and attempted solutions to them.

Characteristics of Pulse Drive Signal

In order to reduce cost of equipment, inverters that generate drive pulses (also called carrier signal) use rapid switching causing drive pulses to have rise and fall times of pulses to be as short as few nanoseconds (Figure 2), extending the spectrum of these edges to several megahertz. It is much easier, less expensive and thermally more efficient to simply turn on and off current to the motor than to create a gradual ramp up and ramp down of the output voltage. Such short edges of drive pulses are the main culprits of the variety of problems. If the connection between a controller and a motor was done as a proper RF connection, i.e. matching input and output impedances, proper RF-grade cable and alike, many of the problems wouldn’t exist. However, the main purpose of a motor is not proper propagation of signal but rather to perform mechanical work, there is seldom a consideration for high-frequency nature of signals. Here are just some of the problems caused by and/or associated with sharp pulsed drive signals (in no particular order of importance):

- motor bearing damage

- overvoltage and associated insulation damage

- high levels of conducted EMI in power lines and ground

- high level of EMI current in ground causing electrical overstress (EOS) problems

- high levels of radiated EMI from the cables

- mechanical noise

- motor overheating

In the following sections we will consider each of them and discuss mitigation of these problems.

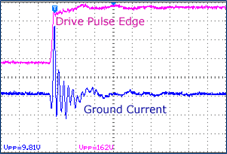

Motor Bearing Damage

Let’s consider a motor as an electronic circuit. Drive pulses with sharp edges are applied to the stator, i.e. inductors on a motor frame. Stator has strong capacitive coupling to the rotor (large metal surfaces of rotor and stator located very close to each other). While the frequency of the drive pulses themselves is fairly low – typically no more than 20kHz and is not a concern – high frequency component of sharp edges of drive pulses experiences little impedance from this capacitive coupling and now rotor has high-frequency voltage which is synchronized with drive pulse edges. This voltage, in turn, causes current flow to ground through the only path it can flow from the rotor – motor’s bearings. Figure 4 shows how ground current is perfectly synchronized with the edges of the drive pulse.

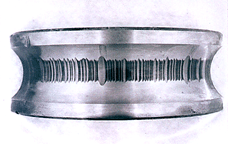

The contact between the bearings’ balls and bearing races is highly intermittent, exacerbated by presence of insulated lubricant[1]. The resulting current in bearings is arcing which, in turn, leads to a phenomenon called EDM – electrical discharge machining[2] In essence, sparks “eat” metal in small pieces at a time. This phenomenon is widely used for work on otherwise hard-to-machine metal parts. With the ball bearings the mechanism of machining the metal is essentially the same; the purpose and the outcome, however, are vastly different. Sparks-caused EDM in bearings starts with tiny craters, or pockmarks, creating discontinuities which cause further discharges and further damage[3]. Voltages on the shaft as low as 200mV are capable of causing sparking[4], although induced voltage on the rotor can be quite high – up to tens of Volts[5]. Once a pockmark is created, it becomes a focus point of further discharges. Since the drive pulses and resulting discharges occur several thousand times per second every second of motor’s operation (see Figure 5), it doesn’t take long to create a permanent damage to the bearing. One of the most common problem is “bearing fluting,” or, so called “racetrack” – see Figure X (ABB). The problem propagates eventually resulting in permanent damage to the motor due to bearing’ failure. This problem is widespread and does not show any signs of diminishing by itself.

Pulse Edge Overvoltage

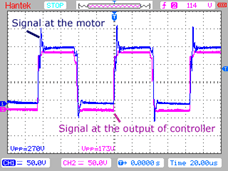

If output impedance of the motor controller, input impedance of the motor and the impedance of the connecting cable were perfectly matched, the drive pulses would be perfect square wave pulses. Alas, motors are not RF devices, no one attempts to match the impedance, plus should anyone attempt this it wouldn’t work anyway. Mismatched impedance causes ringing and overshoots. Figure 6 shows rather mild cases of ringing and overvoltage, although in many cases the overvoltage may easily exceed 60% of the normal pulse amplitude[6]. The red trace is the drive signal directly at the output of a controller; blue trace is the same signal at the motor after 3′ (~1m) of cable. Needless to state that such overvoltage and ringing only increase ground current through the bearings. According to U.S. Department of Energy[7], “The fast rise time pulses from a PWM VFD can … create a potentially harmful current flow in bearings even when overvoltage is not significant.” Overvoltage not only causes further beadings damage, but also stresses insulation of the cables and of the internal wiring of the motor, in addition to other problems, including potential controller drive circuit damage, motor overheating and acoustical noise, not counting less grave effects. This problem is widely recognized. IEC/TS 60034-25[8] (merged with IEC/TS60034-17) states that the pulse voltages at the terminals must not exceed 1,350 V on motors with standard insulation. In case of pulse voltage rise times of less than 0.8 μs at the motor terminals, the permissible pulse voltage is reduced to ~900V for pulsed with 50nS rise/fall times shown in Figure 3. NEMA MG1-2014[9] also addresses issue with EMI-caused bearing damage and associated problems.

EMI in Equipment

It would be incomplete to focus only on motor damage or overvoltage aspects of high-frequency drive signals in VFD/servo motors. The motors do not work in isolation – they are installed in equipment which may be susceptible to EMI caused by operation of the motor(s). High-frequency interference from drive’s operation is capable of:

- non-compliance with EMC regulations

- interference with operation of electronics

- errors in measurements and in sensors’ outputs

- electrical overstress (EOS) to sensitive components

Generation of drive pulses causes sharp changes in current consumption from the mains which, in turn, causes high-frequency conducted emission flowing back into these mains. Compliance efforts largely consist in utilizing power line EMI filter on mains which is recommended by most servo/VFD manufacturers. This may help with electromagnetic compliance. However, there are no current EMC regulations governing EMI inside the tools, most regulations concerning themselves with how a particular equipment may possibly affect operation of other equipment. Failure to manage EMI inside the tool causes it to interfere with itself, especially in cases of composite tool where motion equipment is combined with other electronics by the user or integrator into one tool – in such cases interoperation of different pieces of equipment is not as rigorously checked as if the tool was manufactured by just one company.

Most of internal EMI problems from drives are caused by drive pulses and manifest themselves as radiated emission from sharp edges of drive pulses, noise on the tool’s ground, including tool’s frame, and induced conducted emission on tool’s wiring which is seldom filtered inside the tool. The ground current going through the bearings in the motor as was described above pollutes the entire ground of the equipment, reducing signal-to-noise ratio in data lines, altering signal from sensors, resulting in process variations, sometimes causing life-threatening situations, such as false readings in MRI[10]. Some studies indicate that voltage as low as 1V between neutral and ground may cause equipment malfunction[11]. To a smaller degree, capacitive coupling between the drive cables and the equipment’s ground[12] also contribute to noise on ground.

Electrical overstress (EOS) can also be caused by EMI from servo motors[13] and VFD. Substantial voltage difference between grounded parts in the semiconductor and PCB assembly equipment can expose sensitive devices to electrical overstress, often causing either instant or latent damage where the device passes the test in manufacturing but soon fails in the field. The particular problem is that EMI voltage on ground has very low output impedance and resulting strong current capacity, damaging devices at very low voltage differential. The most fundamental standard in PCB assembly – IPC-A-610[14] – limits the voltage applied to sensitive devices, especially transient voltage characteristic for EMI from the motors to as low as 300mV. EOS is becoming increasingly important in yield and reliability considerations for electronic devices.

Measurements of EMI Caused by VFD/Servo Motors

“You cannot control what you cannot measure,” goes a profound saying. Conducted emission measurements on AC mains done solely for the purpose of electromagnetic compliance are well-known, are thoroughly documented elsewhere, and don’t need to be repeated again. Rather, this section points to measurements not normally covered by EMC regulations but are rather important for reliability and operability of equipment.

Measurements of Bearing Current

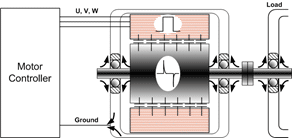

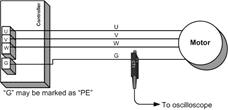

Needless to say, direct measurements of current through rotating bearings is not a practical endeavor at the least. However, reasonably relevant measurements can be made by measuring current in the return path of the drive signal, i.e. current in ground wire between the controller and the motor as shown in Figure 7.

The basic premise is that the current through the bearings must return to its origin – motor controller. The return path is via ground wire (sometimes designated as PE – “power earth”). While there is some purely capacitive high-frequency current path between the stator windings and a grounded motor enclosure, it is insignificant in comparison with the current through bearings, making measurements of high-frequency current in ground wire sufficient for estimate of current through bearings. Figure 7 shows the basic setup which is applicable for both servo motors and VFD. These motors have three drive lines commonly, but not exclusively, designated U, V and W, and ground wire G, or sometimes designated PE. Broadband current probe on this ground wire carries return current passed via the bearings.

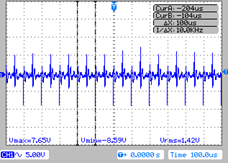

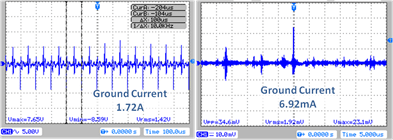

Figure 8 shows typical current through ground wire as measured with Tektronix’ current probe CT1[15]. This probe has 5mV/mA sensitivity. All measurements of current in this paper were done using this method. As seen, peak current is 1.72A – quite significant value. This peak current is applied to the bearings 10,000 times per second, every second (servo motor is working even then it is not moving – maintaining its position). Not surprisingly, the damage to bearings is likely, as well as other undesirable effects – interference with operation of tool and electrical overstress.

Measurements of Drive Signal – Overvoltage and Ringing

Here we are entering territory where reader must pay attention to safety since drive signals may have high voltage (up to 480V) with strong current capability. Exposure to such voltages may cause injury or death. If you are not accustomed with working on live high voltage lines you should defer test, or at least, its “connecting” part, to a properly trained and experienced specialist.

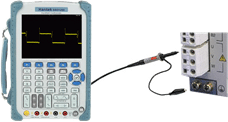

You would need a battery-powered oscilloscope (spectrum analyzer won’t do and the AC-powered oscilloscope would create ground loop due to its connection to a facility’s ground) with the bandwidth of at least 200MHz (higher bandwidth won’t offer any advantage) and 100:1 high voltage oscilloscope probes. Regular 10:1 probes won’t attenuate drive signal sufficiently enough to prevent clipping the signal. Very important: if you value your oscilloscope, you will set its input to 1MOhm rather than 50 Ohms – high voltage and low impedance don’t play well together. This may add some small ringing artifact to the signal, but this is better than a damaged oscilloscope.

At most motor controllers you would find terminals labeled U, V and W – these are the outputs to the motor. Connect ground of the probe to the controller’s ground and the tip of the probe, perhaps with some extension, depending on the terminals’ construction, to any of U, V or W terminals (Figure 9). Ground of the scope’s probe should go to the controller’s ground terminal which is located in the immediate proximity to the U, V and W terminals. It would be helpful to make several measurements setting time base of the oscilloscope to capture several drive pulses, rise edge of a pulse and a fall edge of a pulse.

You should expect nearly square wave drive signal at the good-quality motor controller terminals. Measurements at the motor are much more tricky and often seem nearly impossible due to termination and hard-to-get issues, but with the help of equipment specialist it may be possible. Make sure that ground clip of an oscilloscope probe is connected to ground terminal at the motor itself, not anywhere else, otherwise the test results are severely compromised.

Mitigation of EMI Problems in VFD/Servo Motors

Ultimately, all the problems described above are caused by and/or related to sharp edges of drive pulses. Therefore, the solution to these problems would be to modify pulse edges so that the rise and fall times are slow enough for the capacitive coupling between the stator and the rotor not to be a strong conductive path; all while maintaining operability of the motor. There are partial solutions involving optimized cabling and altering the path of current through the bearings or blocking this path altogether. The problem with PWM-driven motors is not a new one and is quite wide-spread – there is a number of solutions which we will examine in further chapters. Given the wide spread of this problem and its financial impact, there is a number of solutions available to motor users, performing with various degrees of success. The field of preventive measures for VFD and servo motor problems is very competitive – a user is advised to pay attention to factual technical analysis vs. the intensity of sales hype in selecting a solution to the motor’s problems.

Optimized Cabling

Needless to say, a shorter motor cable offers less ringing and less emissions than a longer one. A cable to the motor routed separately from other cables induces less voltage and currents into other conductors. Good properly connected shield (copper braided) helps with reducing electromagnetic field from the pulse edges.

There are special cables manufactured for VFD and servo drivers. A better cable between the controller and the motor is properly shielded one (copper braided shield) with sufficient gauge. Some cables have separate ground wires for each phase[16] which further reducing ringing. User is discouraged from using regular cables not specifically intended for VFD applications since they may exacerbate the problems.

Importantly, better cabling does not by itself change how sharp the pulse edges are. Ringing of course affects pulse edges but not to the degree where this becomes noticeably effective.

Insulated Bearings

One approach to prevent high-frequency current going through bearings is to make bearings non-conductive. Ceramic-coated bearings[17] electrically isolate rotor offering no galvanic connection from rotor to ground. Capacitive coupling across ceramic coating still remains, however, providing some significantly smaller current than it would be otherwise.

The coated bearings focus narrowly on bearing damage problem, leaving most of other problems, such as EMI from the cables and others, intact. Another challenge with coated bearings is that they need to be designed for each type of shaft and two of them have to be uses on each side of the motor, affecting cost and installation. High frequency voltage residing on the rotor will still be shared with motor’s load via conductive coupling, subjecting its bearings to destructive current.

Shaft Grounding

Another mechanical solution is grounding of the rotor’s shaft using special brushes[18] or other electrical contacts that essentially short-circuit high-frequency currents to ground bypassing bearings. Just like insulated bearings, these solutions are narrowly focused on reducing damage to bearings and reducing voltage on conductively-connected load. However, they still leave high-frequency currents in equipment ground intact, as well as preserving EMI problems associated with drive signal pulses. Any mechanical solution requires periodic checks and, if needed, repair or replacement. Naturally, the bypass contacts must be installed on both ends of the rotor’s shaft and they have to be tailored to the specific motor type. When using shaft grounding contacts or brush you must connect motor’s case/ground to the load’s ground in order to protect equipment[19]

Ferrite Core Ring

A simple ferrite core put over three motor drive wires (U, V and W) provides limited common mode rejection similar to typical ferrite core applications. However, given simplicity of installation and relatively low cost, sometimes just a little bit of improvement may be sufficient. The ferrite cores for this purpose are usually oval to accommodate three drive wires. They may be either split-core or solid. Important considerations are saturation – if the core isn’t “beefy” enough, it will saturate just when it is needed the most – and the frequency response, which should be geared more towards lower frequencies. Just like any filtering solutions described further in the paper, ferrite core shall be positioned close to the drive controller, not to the motor, to lessen emission coming from the cable.

Load Reactors

An output (or load) reactor connects between the controller and the motor. It is simply three separate inductors on a common core connected in series with the phases of the drive signal of the motor. Reactor’s main function is to extend dV/dt time of rise and fall edges of drive signals. Increased dV/dt time “spreads” drive pulse edges, typically 3 to 5 times[20],[21]. Reactors are installed close to the motor controller in order to reduce emission from the ca

bles. Reactors benefits include:

- lower current through the bearings

- overall reduction of EMI in equipment

- lower “ringing” of drive pulses, allowing for longer cables between the controller and the motor

- lower temperature of motor

Unlike mechanical solutions, reactors are selected solely on the basis of their electrical performance and do not need to be either fitted to a particular motor nor need to be checked or maintained. Reactors can be added after installation without much effort and with no mechanical work on a motor. Reactors not only help with the bearing damage and overvoltage, they also reduce ground current and overall EMI in equipment. On a flip side, they provide very marginal performance improvement – both in increasing dV/dt (i.e. “slowing down”) of pulse edges. Wherever just a small improvement is required, a reactor may be a reasonable choice.

Motor Filters

There are two basic types of motor filters – sinewave and dV/dt. Both are enhanced versions of reactors, adding more filter stages and other enhancements.

Sinewave Filters

Sinewave filter[22] is essentially a low-pass LC filter in each phase of the motor which converts PWM into corresponding sinewave with the approximately same RMS voltage as the original PWM signal Sinewave filter offers advantages of greatly reduced EMI in all aspects. They also can be retrofitted in existing installations. Just like a reactor they needs no periodic test or maintenance. Sinewave filters, though, work only with certain types of motors (i.e. they cannot be used with servo motors); cannot be used at lower switched frequencies due to possible internal capacitor damage, and are bulky.

dV/dt Filters

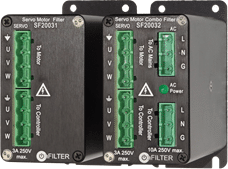

These are arguably the most versatile filters which perform quite well with both VFD and servo motors. The dV/dt filters “stretch” the rise and fall times of the drive pulses thus reducing high-frequency spectral content of the drive signal which, in turn, reduces capacitive coupling between the stator and the rotor and resulting current through the bearings and ground current, as well as overall EMI levels in host equipment. Just like sinewave filters and reactors, they require no periodic test or maintenance and can be installed “after the fact.” Due to their versatility and wide range of applications, we will examine their performance more closely. We will do so on example of SF series servo/VFD dV/dt filters manufactured by OnFILTER (Figure 10), as the ones on which the author performed most of the tests.

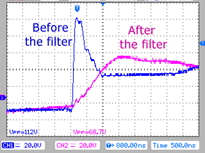

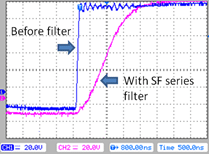

Figure 11 shows typical pulse edge “stretch” with VFD/servo motor filter SF series by OnFILTER[23]. As seen, the rise time increased from under 100nS to almost 2µS. How significant is it? Let’s consider Figure 12 which shows how this filter removes overvoltage caused by sharp rising edge of the pulse. When a filter is placed right at the output of the motor controller, the drive signal on cable is largely free of sharp edges which reduces overshoots and resonances, as well as radiated and coupled EMI in the tool.

What about ground noise? Figure 13 shows how to measure ground current; Figure 14 shows the results. Just like before, measurements were done using Tektronix’ CT1 current probe. As seen, SF series filter is capable to substantially resolve ground current situation. Unlike reactors and regular VFD/servo filters, patent-pending SF-series motor filters utilize proprietary additional filtering stages which allow for reduction of ground current down to a negligible level.

Some filter models, such as patent-pending SF20032 (Figure 10) uniquely combines filtering of load and filtering of AC noise in one small package, providing complete EMI coverage for a drive. This saves cost and precious real estate inside equipment – all filters and/or reactors must be located as close to drive controller as possible in order to maximize their effectiveness.

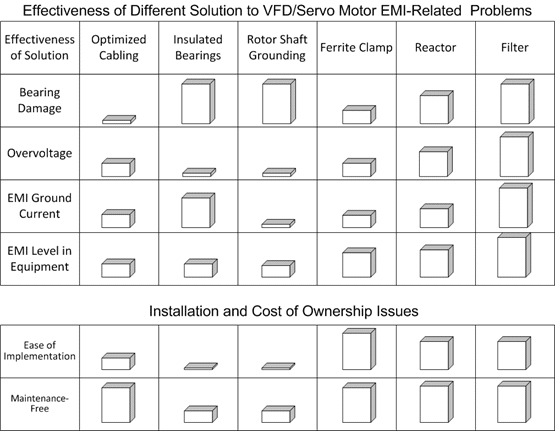

Figure 15 shows the summary of different methods of reducing EMI and its effect on the drives, cables and host equipment.

Conclusion

The inherent problems with PWM motors – VFD and servo – are not going away and with increase of automation and associated motor use, they are only going to increase. EMI mitigation solutions address these issues at their core and are capable of help the whole industry to improve reliability of equipment, increase its up-time and reduce cost of operation.

Vladimir Kraz

OnFILTER

vkraz@onfilter.com

831-824-4052

[1] Angular Contact Ball Bearings Passed By Electric Current, C. Raocea et. al., 6th International Multidisciplinary Conference, 2005

[2] Elman C Jameson, Electrical Discharge Machining, Society of Manufacturing Engineers, 2001

[3] Bearing Currents in modern AC drive systems, ABB ,2011

[4] Bearing Currents and Their Relationship to PWM Drives, D. Busse, et. al. Allen Bradley, 1995

[5] Inverter Driven Induction Motor Bearing Current Solutions, R.F. Schiferl, et. al.,Rockwell Automation, 2002

[6] Modeling and Evaluation of dv/dt Filters for AC Drives with High Switching Speed, Moreira A.F. et. al, 9th European Conference on Power Electronics and Applications, 2001

[7] U.S. Department of Energy, Advanced Manufacturing Office Motor System Tip Sheet #15

[8] IEC TS 60034-25:2014, Rotating electrical machines – Part 25: AC electrical machines used in power drive systems – Application guide

[9] NEMA MG1, Motors and Generators, 2014

[10] EMI Issues in Electric Drives, Wayne State University

[11] Demystifying Isolated Grounding Systems, K. Michaels, Electrical Construction and Maintenance, 1999

[12] Solution of EMI Problems from Operation of Variable-Frequency Drives, Pacific Gas and Electric Company (PG&E), 2000.

[13] EMI-Caused EOS Sources in Automated Equipment, V. Kraz, Proceeds of IPC APEX, 2015

[14] IPC-A-610F, Acceptability of Electronic Assemblies, 2012

[15] AC Current Probes, CT1, CT2, CT6 Datasheet, 60W-12572-4, Tektronix, 2013

[16] Choosing the Right Cable for Your Variable Frequency Drive (VFD) System, B. Shuman, Belden, Inc., 2013

[17] Schaeffler KG, Current-Insulated Bearings Prevend Damage Caused by Electrical Current, 2007

[18] Aegis Shaft Grounding Ring Bearing Protection Handbook, Electrostatic Technology, 2013

[19] Inverter Driven Induction Motor Bearing Current Solutions, R. F. Schiferi et al., IEEE Paper PCIC-2002-08

[20] Load Reactors RWK305, Schaffner, 2016

[21] RL Reactors, MTE Corporation, 2013

[22] Sine Wave Filter Solutions for Motor Drive Applications, Schaffner, 2013

[23] Improving Reliability of Servo Motors and VFD with Servo Motor Filters, OnFILTER 2015