Is there a need for a distinct testing lab standard and calibration lab standard?

Daniel D. Hoolihan, Hoolihan EMC Consulting, Lindstrom, MN

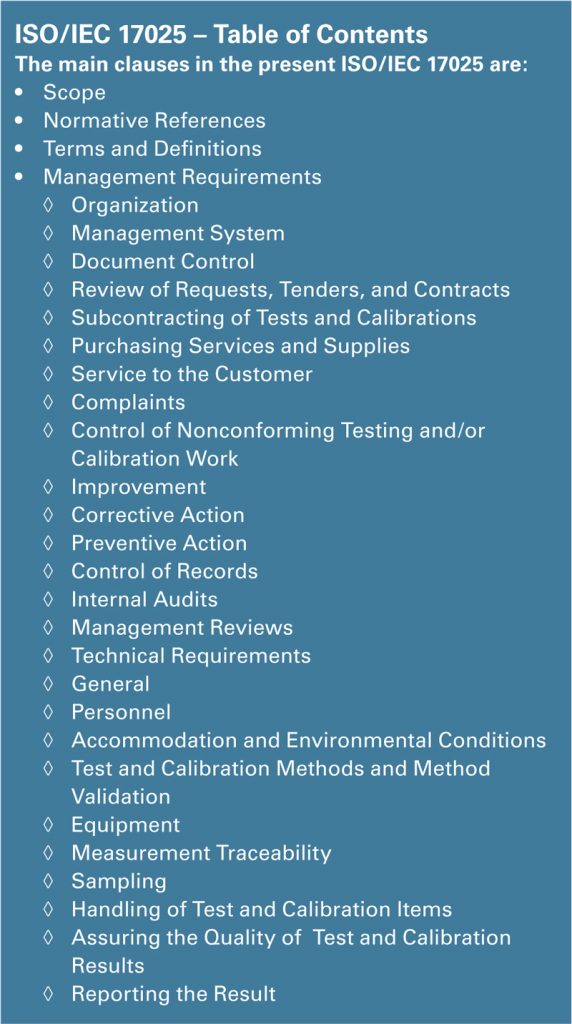

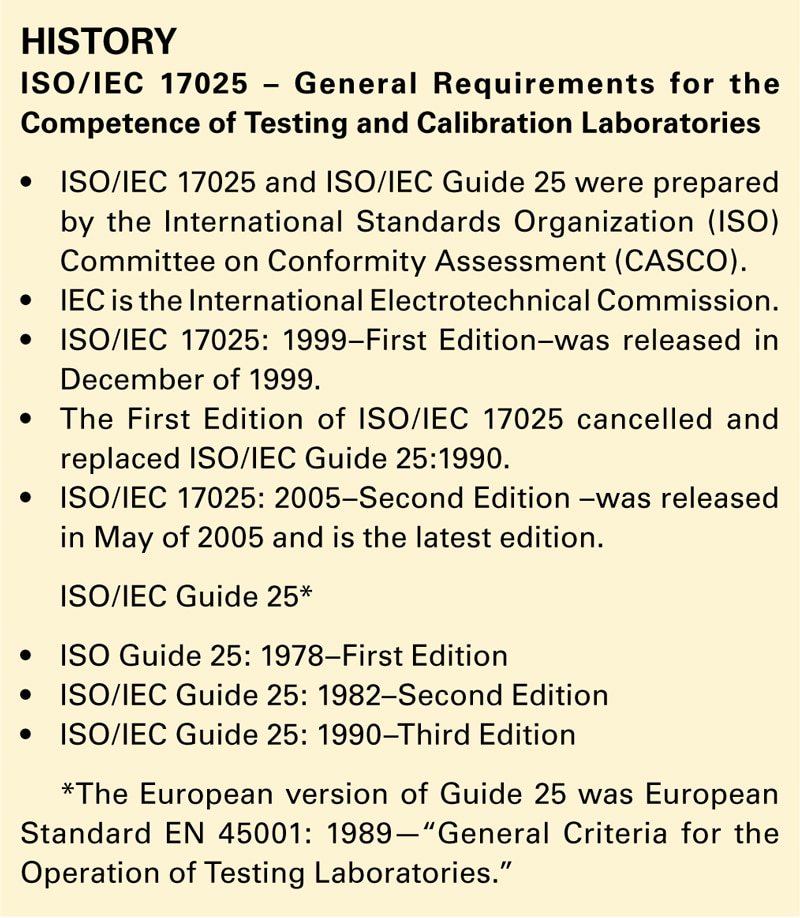

The flag-ship laboratory quality standard in the world is ISO/IEC 17025–General Requirements for the Competence of Testing and Calibration Laboratories. Based on years of experience using the standard, the author is recommending that the standard be divided into two standards—one for testing laboratories and one for calibration laboratories. This recommendation is based on the confusion that arises in Clauses 4 and 5 of the standard’s treatment of the essential missions of testing labs and calibration labs. Another factor is the unique, vital procedures carried out by all calibration labs. In contrast, testing labs deal with a wide range of disciplines; any given test lab might not offer the capabilities of other facilities operating as test labs. A look at the Table of Contents of the present standard is instructive.

Clauses 1–3

The first three clauses of the standard are Scope, Normative References, and Terms and Definitions. Clearly, the scope would have to be changed since it attempts to address both testing and calibration laboratories. A modified Clause 1.1 might read as follows for testing labs: This International Standard specifies the general requirements for the competence to carry out tests including sampling. It covers testing performed using standard methods, non-standard methods, and laboratory developed methods.

And for calibration labs, Clause 1.1 would read: This International Standard specifies the general requirements for the competence to carry out calibrations including sampling. It covers calibration performed using standard methods, non-standard methods, and laboratory-developed methods.

The Normative References in Clause 2 would change only slightly for either the testing or the calibration laboratory standard. Similarly the Terms and Definitions in Clause 3 would also remain much the same for both testing and calibration labs since this clause simply cross-references ISO/IEC 17000 (Conformity Assessment – Vocabulary and General Principles) and VIM (International Vocabulary of Basic and General Terms in Metrology).

Clause 4

Management Requirements is the subject of the fourth clause of ISO/IEC 17025. This part of the standard, of course, is closely aligned with ISO 9001. In fact, Annex A of ISO/IEC 17025 is an informational annex that consists primarily of nominal cross-references between ISO 9001:2000 and ISO/IEC 17025. Throughout Clause 4, the term “testing and calibration” would have to replaced with “testing” or “calibration.”

One important clause that would be clarified by splitting the standard into two standards is Clause 4.5 (Subcontracting of Tests and Calibrations). The 2000 version of ISO 9001 changed the definition of “subcontracting” and that has led to much confusion in the laboratory arena. (Clause 3 of ISO 9001:2000 states that the relationship designated by supplier-organization-customer has replaced the older trilogy of subcontractor-supplier-customer from ISO 9001:1994). This confusion is more prevalent in laboratories in non-English-speaking countries.

Thus, for testing laboratories, Clause 4.5.4 would read “The laboratory shall maintain a register of all subcontractors that it uses for tests and a record of the evidence of the compliance of those subcontractors with this International Standard for the work in question.” For testing laboratories, this would eliminate the confusion between “subcontracting testing” and “subcontracting calibration.” In other words, testing labs could subcontract testing to other qualified testing laboratories, but to comply with best practices, they would have to purchase “calibration services” from external vendors. (This requirement is covered under Clause 4.6—Purchasing Services and Supplies). It is hoped that, in the future, we continue to see a continued alignment of the management requirements in ISO 9001 and Clause 4 of ISO/IEC 17025.

CLAUSE 5: Technical Requirements

CLAUSE 5: Technical Requirements

I would recommend that Clause 5.1 (General) be deleted from both the proposed testing and calibration laboratory standards. It appears to be simply a placeholder, and it is very difficult to assess a laboratory to the requirements of 5.1. The measurement uncertainty covered in 5.1.2 could be covered more appropriately in Clauses 5.4, 5.5, and 5.6.

In Clause 5.2 on Personnel, the changes required would be simple semantic changes to distinguish between testing and calibration activities. For example, for testing labs, the first sentence in 5.2.1 would read, “The laboratory management shall ensure the competence of all who operate specific equipment, perform tests, evaluate results, and sign test reports.” For calibration labs, it would read “The laboratory management shall ensure the competence of all who operate specific equipment, perform calibrations, evaluate results, and sign calibration certificates.”

There is a distinct difference in the training and areas of competence between testing personnel and calibration personnel. Testing lab personnel have to be trained in their area of specialty— such as electrical testing, electromagnetic compatibility testing, chemical testing, soil testing, etc. Calibration lab personnel have to be trained in measurement uncertainty, traceability, and calibration lab equipment. It would seem that calibration labs skills would be transferable from one calibration lab to another while a chemical testing lab person would have difficulty transferring to an electrical testing lab.

Clause 5.3 on Accommodation and Environmental Conditions would require very few changes. For example, the first sentence in 5.3.1 would read as follows for testing labs, “Laboratory facilities for testing, including but not limited to energy sources, lighting and environmental conditions, shall be such as to facilitate correct performance of the tests.” In many technical disciplines, the environmental conditions for calibration laboratories are more stringent than the environmental conditions for testing laboratories.

The title of Clause 5.4 should be altered to read “Test Methods and Method Validation” for testing labs. For calibration labs the title would read “Calibration Methods and Method Validation.” There would be a separation of testing and calibration throughout the clause to differentiate between the two functions. It would be appropriate to move Clause 5.4.5.1 into Clause 3 (Terms and Definitions) since it is the definition of validation—viz., “Validation is the confirmation by examination and the provision of specific evidence that the particular requirements for a specific intended use are fulfilled.”

Clause 5.4.6 on Estimation of Uncertainty of Measurement would have to be rewritten to clarify the intent. For example, Clause 5.4.6.1 would read as follows for calibration laboratories, “A calibration laboratory shall have and shall apply a procedure to estimate the uncertainty of measurement for all calibrations and types of calibrations.” Clause 5.4.6.2 would be eliminated for calibration laboratories. Clause 5.4.6.3 would remain the same—viz., “When estimating the uncertainty of measurement, all uncertainty components which are of importance in the given situation shall be taken into account, using appropriate methods of analysis.”

For testing labs, Clause 5.4.6.1 would read, “A testing laboratory performing its own calibrations shall have and shall apply a procedure to estimate the uncertainty of measurement for all calibrations and types of calibrations.” Clauses 5.4.6.2 and 5.4.6.3 would remain the same for testing laboratories. This separation of Clause 5.4.6 would help clarify the confusion of testing labs as to whether or not they can “calibrate” their own equipment. In other words, there seems to be a hierarchy of good calibration practices for a testing laboratory:

- The highest level is for a testing lab to send its test equipment

to an accredited calibration laboratory. This level of

service provides the testing lab with calibrated equipment

accompanied by a statement of measurement uncertainty

for the calibration. - In the second level, the testing lab calibrates its own equipment.

The testing lab must use equipment that is traceable,

and it must calculate its own measurement uncertainty

using its traceable equipment. - In a third level, the testing lab uses a non-accredited calibration

lab. The testing lab must check the traceability of

the calibration lab, and the testing lab must calculate its

measurement uncertainty using the traceable equipment

of the non-accredited calibration lab. - Finally, a testing lab may verify some of its equipment;

to do this, it uses traceable equipment, but it does not

calculate the measurement uncertainty.

- Clause 5.5 on Equipment would require some simple changes in wording depending on the type of lab. For example, Clause 5.5.12 would read as follows for testing labs,

“Test equipment, including both hardware and software, shall be safeguarded from adjustments that would invalidate the test results.” For calibration labs, it would read, “Calibration equipment, including both hardware and software, shall be safeguarded from adjustments that would invalidate the calibration results.”

Clause 5.6 on Measurement Traceability would see major changes. Clause 5.6.1 would require slight rewording for calibration labs, and Clause 5.6.2.1 would survive only for calibration labs. Clause 5.6.2.2 would be eliminated for calibration labs, and Clause 5.6.3 on Reference Standards and Reference Materials would remain for calibration labs.

For testing labs, Clause 5.6.1 would be reworded to read, “All equipment used for test, including equipment for subsidiary measurements (e.g., for environmental conditions) having a significant effect on the accuracy or validity of the result of the test or sampling shall be calibrated before being put into service. The laboratory shall have an established program and procedure for the calibration of its equipment.” Clause 5.6.2.1 would be deleted for testing labs, and Clause 5.6.2.2 would be rewritten to cover the requirements necessary for testing labs. Clause 5.6.3 would remain for testing labs.

Clause 5.7 on Sampling would remain basically the same with some simple changes in wording to distinguish the testing and calibration activities.

Clause 5.8 on Handling of Test and Calibration Items would need a change in title. Obviously, for testing labs, it would become “Handling of Test Items.” For calibration labs, it would become “Handling of Calibration Items.”

Clause 5.9 would be titled “Assuring the Quality of Test Results” for testing labs and Clause 5.9.1 would read “The laboratory shall have quality control procedures for monitoring the validity of tests undertaken.” For calibration labs, the title would be “Assuring the Quality of Calibration Results.” Clause 5.10 would be rewritten focus on test reports for testing labs and calibration certificates for calibration labs.

SUMMARY

Testing laboratories and calibration laboratories are distinctly different in their operations and their areas of specialty. Testing laboratories cover a wide range of concerns including electromagnetic compatibility, acoustics, environmental, shock/vibration, soil testing, chemicals, and other areas. Calibration laboratories calibrate test equipment that is used by these testing laboratories. There is a great deal of similarity between calibration laboratories, there may be very little similarity between testing laboratories. It would be a reasonable division of duties to rewrite ISO/IEC 17025 into a testing lab standard and a calibration lab standard. It would be greatly appreciated by lab assessors and by laboratories (especially those in non-English speaking countries) around the world.

Daniel Hoolihan is a past president of the IEEE EMC Society. He has been a member of the Board of Directors since 1987 and has held numerous leadership positions in the society. Dan is also active on the ANSI Accredited Standards Committee on EMC, C63 as Vice Chairman. He was co-founder of Amador Corporation (1984-1995). He can be reached at DanHoolihanEMC@aol.com.