Co-authored by: Ranjith Bramanpalli & Steffen Schulze

Würth Elektronik

INTRODUCTION

Input filters are today as ever a requisite factor for successful EMC validation of switching controllers, irrespective of the size of the AC component involved. Switching controllers create conducted EMC interferences due to AC components in their lines, independent of their individual topology and application. Certain component manufacturers have therefore optimized their power modules for a low line-bound and radiated emission of interferences. These types of modules’ residual ripple generally exhibits a negligibly low value, meaning that an output filter can be dispensed within most applications. Since the input current at the step-down converter is pulsating, this may generate radio-frequency interferences in the application. Depending on the specific application, the hardware developer decides whether an input filter is necessary directly before the power module or in another position in the switch. The design process of input filters for optimized power modules and the measurement techniques that are used is discussed in this article.

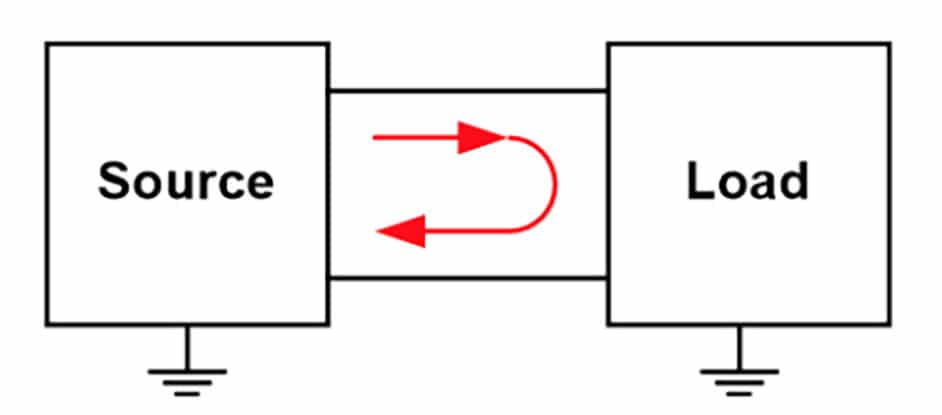

As a starting point it is useful to illustrate how differential mode noises develop in the first place. Differential mode noises are interference signals in a system with a symmetrical current back and forth between the source and the load in the lines of a switching controller.

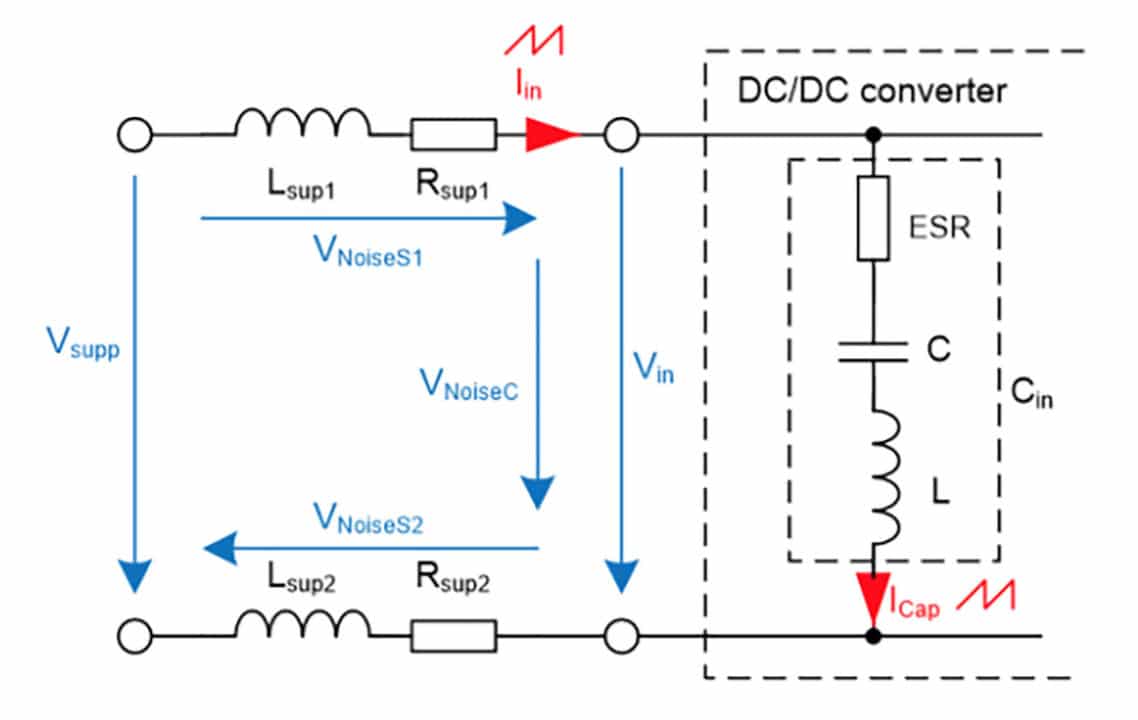

In the input circuit, the clock frequency of the power module includes an AC component superimposed over the useful current and is similar in its configuration to the current through the storage inductance of the power module. The input current flows into the input capacitor Cin. Real capacitors possess a resistive component, the ESR, and an inductive component, the ESL as shown in Figure 2.

Due to the ESR of the input capacitor and the impedances of the lines of the power module, the AC component produces an undesirable voltage drop.

In this form, the noise voltage shows up as a differential-mode signal. The amplitude of the interference voltage occurring at the input capacitor is essentially dependent on the ESR of the capacitor used. Electrolytic capacitors have a relatively high ESR, the value of which can range between just a few milliohms up to several ohms. As a consequence, the interference voltage can vary between a few millivolts up to several volts. Ceramic capacitors, on the other hand, have a very small ESR of just a few milliohms and thus result in a noise voltage of a few millivolts. In addition, the circuit-board design of the power module exerts a great effect on the interference voltage.

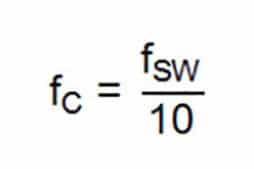

To reduce differential mode noises, at least one simple LC filter must be fitted at the input of the converter as a measure to minimize the AC component in the line. In high-impedance systems, such an input filter can theoretically produce a voltage attenuation of 40 dB/decade in the stopband. In practice, a lower degree of attenuation is achieved since the terminating impedances are low-ohm in their nature and also because the components themselves exhibit losses. In dimensioning the LC filter a corner frequency fc is selected that is below the switching frequency fsw of the power module. If the factor is one tenth, theoretically an insertion loss of 40 dB is achieved at the switching frequency at which the highest spectral amplitude occurs.

(1)

(1)

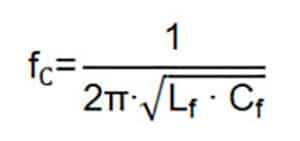

The corner frequency of an LC filter is generally:

(2)

(2)

As an example for the calculation of the filter, an inductance of 10 μH is selected and equation (2) is transformed to

![]() (3)

(3)

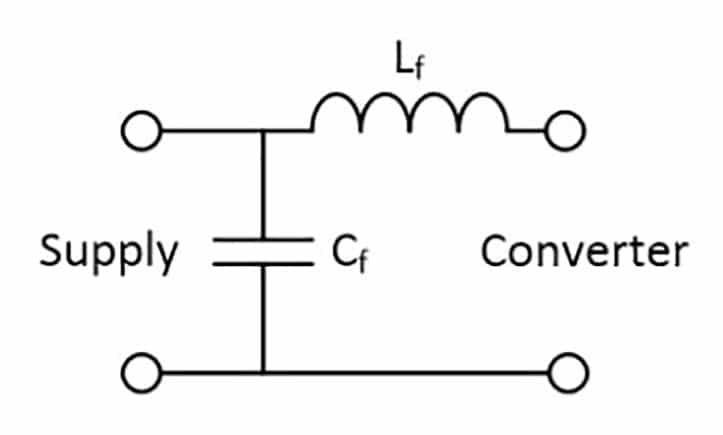

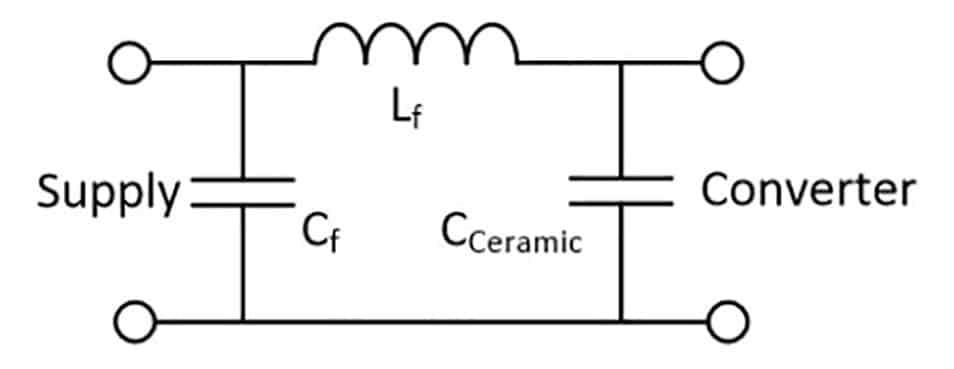

In arranging the filter components, as shown in Figure 3, the filter capacitor can be positioned on the side of the voltage source or on the input side of the power module. The decisive factor for the attenuation of the pulsating current drawn from the voltage source is the inductance of the filter inductor.

When the quality of the filter resonance is too high, oscillations may occur in the event of changes in the input voltage that must be regulated. The stability criterion that applies here is that the output impedance of the input filter Zout,filter within a broad frequency spectrum has to be lower than the input impedance of the power module Zin,converter

(4)

(4)

In addition, the corner frequency fc of the input filter should lie far below the crossover frequency fco of the power module.

(5)

(5)

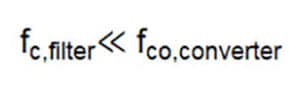

Figure 4 shows how this is done by placing an attenuating branch parallel to the power module input.

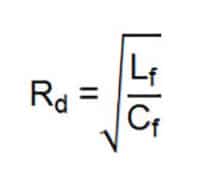

The attenuator reduces the quality of the input filter and consequently its output impedance at the resonance frequency. Equation (6) can be applied to calculate the attenuation resistance Rd for a filter quality of Qf=1:

(6)

(6)

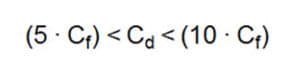

A value that has established itself in practice as an indicator of the capacity of the attenuation capacitor Cd is the five-to-ten-fold measure of the filter-capacitor capacitance.

(7)

(7)

As an alternative, the filter can be attenuated by selecting an electrolytic capacitor that is switched parallel to the filter output instead of the attenuator. As a rule, the value of the ESR of the electrolyte capacitor is sufficient to attenuate the filter.

SELECTING THE LC FILTER COMPONENTS

Both capacitors and coils show capacitive as well as inductive properties in reality. Filter inductors have their highest filter effect at their self-resonant frequency (SRF). In coils, the SRF is strongly dependent on the inductance and the capacitive coupling between the winding turns. In capacitors, the SRF is strongly dependent on the capacitance and the length of their terminations. When selecting the filter components, it is hence advisable to make sure that the SRF is at the upper end of the frequency range in which the RFI voltage is at its maximum or, respectively, in which the filter is to be active.

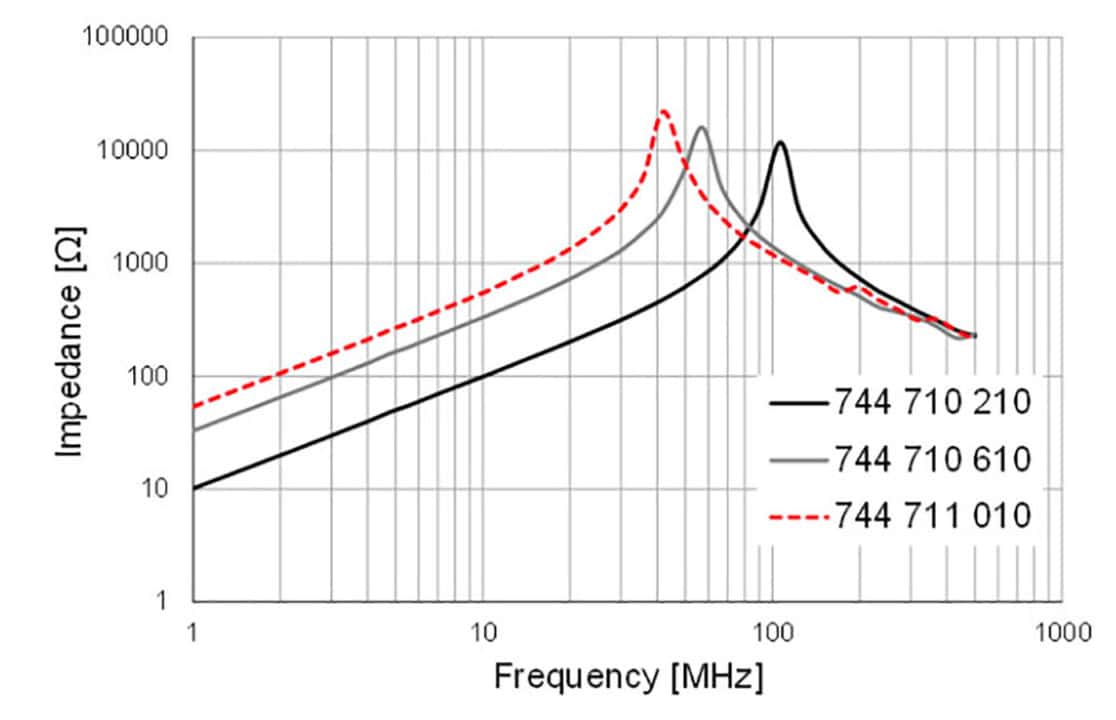

The decisive factor for the reduction of the differential-mode noise is the filter inductor, since this is the component that counteracts the rapid rise and drop in the current in the input circuit. Figure 5 shows the impedance curves of three rod core chokes based on an example of the Würth Electronics WE-SD product family.

The higher the inductance, the smaller the SRF. It is recommend-ed to select an inductor with an inductance whose numeric value is lower than the capacitance of the filter capacitor. In practice, a filter inductance with a maximum value of 10 μH is selected, since – depending on the design – such an inductance has a self-resonant frequency of approximately 30 MHz.

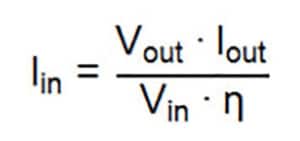

Exceeding the rated current of the filter inductor may result in damage to the wire winding. Taking the efficiency of the switching controller as a basis, it is possible to calculate the effective input current of the power module using equation (8).

(8)

(8)

For safety reasons, a larger value should be selected as the rated current of the filter coil.

The filter capacitor may take the form of a liquid electrolyte capacitor, a polymer capacitor, or even a ceramic capacitor. The only aspect that must be considered is that the filter quality at the corner frequency is sufficiently low (see Section 4).

Further measures must be considered when dimensioning a Π filter. In the optimal case, an input filter should be placed as close as possible to the input of the power module. For the case that the in-put filter is placed further away due to geometric circumstances, the traces may act as an antenna between the input filter and the power module at higher frequencies. The trace inductance can, however, also be used together with a ceramic capacitor to establish an additional LC filter with a higher cut-off frequency (see Figure 6). Due to its negligibly low ESR, a ceramic capacitor can swiftly short-circuit high-frequency voltages to ground with low impedance.

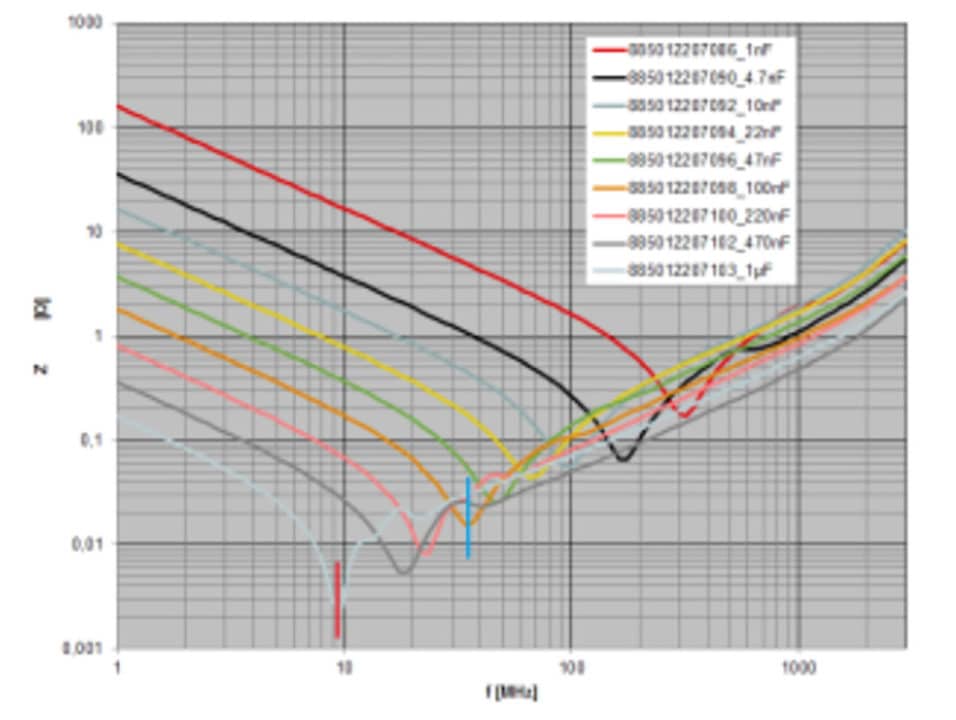

The SRF of the capacitor should roughly lie within the spectrum of the switching frequency of the power module. To illustrate this point, Figure 7 shows impedance curves of Würth Elektronik WCAP-CSGP ceramic capacitors in the 0805 size.

Of the components shown in Figure 7, at a clock frequency of 2 MHz, for example, a capacitor with 1 μF would be suitable (resonant frequency marked in red). Even a 100 nF ceramic capacitor (resonant frequency marked in blue), which is used as a blocking capacitor in numerous electronic circuits, would be a suitable candidate at these values; it should be mentioned, however, that com-pared with the 1 μF version the 100 nF capacitor has an ESR higher by a factor of nine.

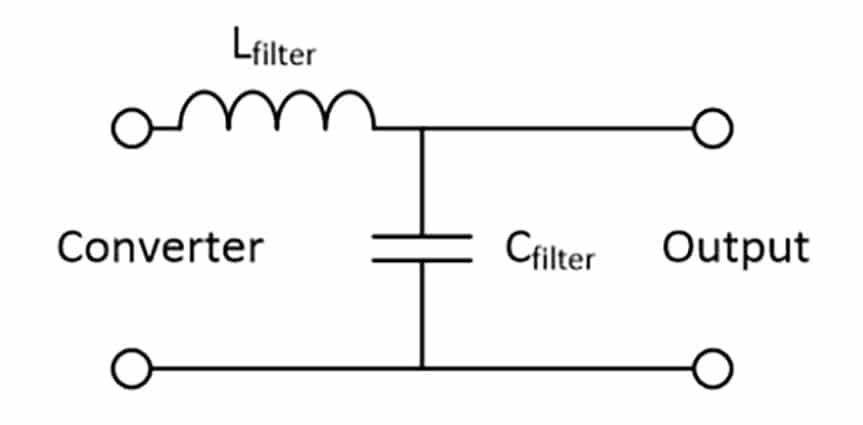

DIMENSIONING AN OUTPUT FILTER

Some power modules on the market, such as Würth Elektronik MagI³C power modules, exhibit a negligibly low residual ripple at the output, which is why an output filter is not absolutely necessary. For the case that components supplied by the switching controller decouple interference signals via interfaces (e.g. sensor switches, analog switching circuits), it may be necessary to include an output filter to filter the output voltage.

The circuit schematic shown in Figure 6 images an output filter as an option comparable to that shown here in Figure 8. It is not generally possible to make a definitive statement on the necessity for and effectiveness of such an output filter, since this must be dimensioned individually for each specific application. It may be possible to use an output filter to reduce the residual ripple of the power module to an absolute minimum, or otherwise to suppress undesirable subharmonic oscillations. The filter can be dimensioned as already described above in Section 3. Attenuation of the filter resonance is not necessary in this case.

MEASURING THE NOISE VOLTAGE

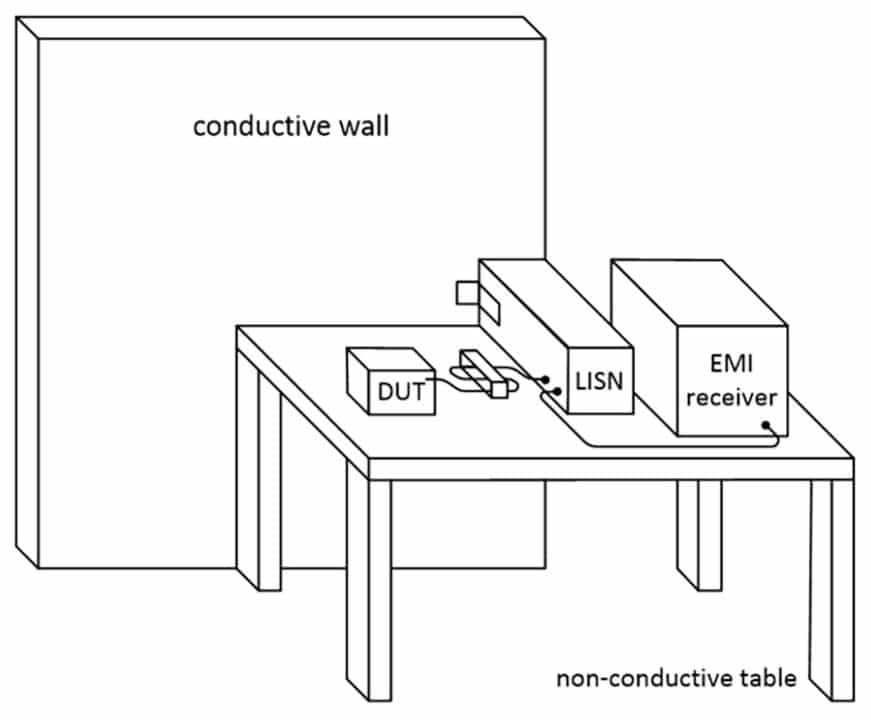

The noise voltage is measured according to the basic standard IEC CISPR 16-2-1, which describes the types of the interference variables to be measured, the equipment to be used for the various interfaces, and the measurement set-up for table-top and floor-standing devices. The interferences are evaluated in the frequency range from 9 kHz to 30 MHz. The measuring devices include besides the EMI receiver a variety of line impedance stabilizing networks (LISNs), voltage probes, current clamps and capacitive couplers. In a measurement set-up for table-top devices, as shown in Figure 9, the test object (DUT, “device under test”) is positioned on a non-conductive table standing on a ground reference plane. The table should be 40 cm in height. In the case that a vertical ground reference plane is also present, the table should be at least 80 cm in height. The LISN must be connected to the ground plane ensuring good conductivity. The DUT itself and any attached cables are to be arranged so that they are 40 cm distant from the ground plane.

The length of the cable between the DUT and the LISN should not exceed 80 cm. The EMI receiver evaluates the asymmetric noise voltage that is decoupled at the LISN for the separate leads of the cable.

MEASURING THE RADIATED NOISE

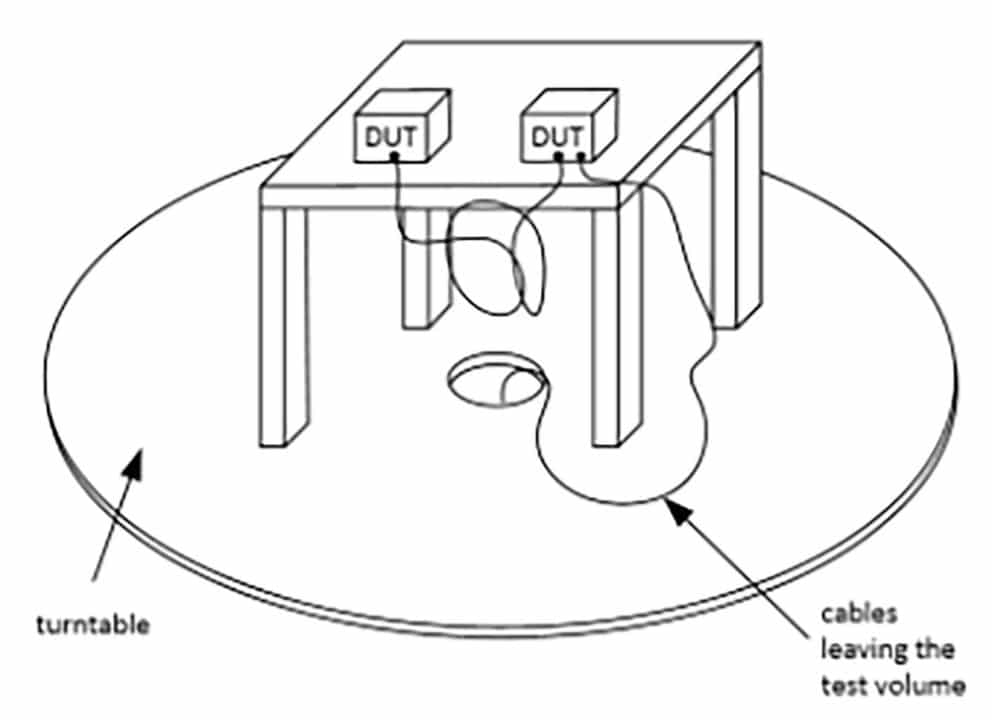

The method for measuring the radiated noise above 30 MHz is de-scribed in the IEC CISPR16-2-3 basic standard. The measurement environment is generally in the form of an anechoic room with a conductive floor or, at a smaller scale, an anechoic chamber. Here, too, the DUT is positioned on a non-conductive table (for portable or table-top devices, see Figure 10) or on the floor. To enable the DUT to revolve on its own axis in its default state during the measurement, it is placed on a turntable. In larger anechoic rooms, the receiving antenna is placed at a distance of 10 m from the DUT and adjusted in its height during the measurement to find the maxi-mum electric field strength at each measurement frequency (peak spectrum). In addition, the orientation of the antenna is altered (horizontal and vertical polarization). In smaller anechoic chambers, the distance between antenna and DUT should be 3 m; since the antenna height needs to be fixed, the height scan is omitted and he floor between the antenna and the DUT must be covered with absorbing material.

CASE STUDY – MEASURED NOISE VOLTAGE

The following section describes the measurement of the noise volt-age using a Würth Elektronik MagI³C power module evaluation board fitted with a Variable Step Down Regulator Module (171 020 601) as an example.

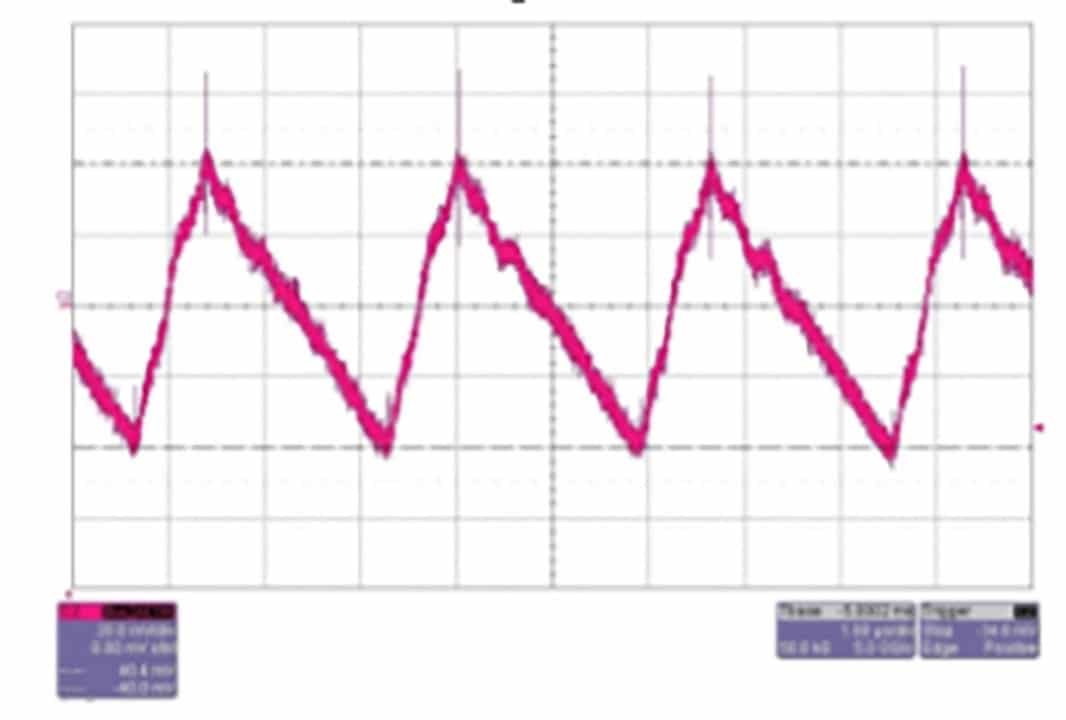

Already during the preliminary phase it is possible to measure the AC component at the power module’s input using an oscilloscope. By running an analysis within the time domain, the anticipated interference spectrum can be estimated at the start of the work on the design of the filter.

Figure 11 shows an AC component of 80 mV, measured at an in-put voltage of the power module of 7.5 V, an average input current of 1.2 A, and an average load current of 2 A. Switching controllers have the property to show up as a negative differential resistance from the viewpoint of the power supply. The input current rises with decreasing input voltage. For this reason, the noise voltage is measured under “worst case” conditions – minimum input voltage, maximum current.

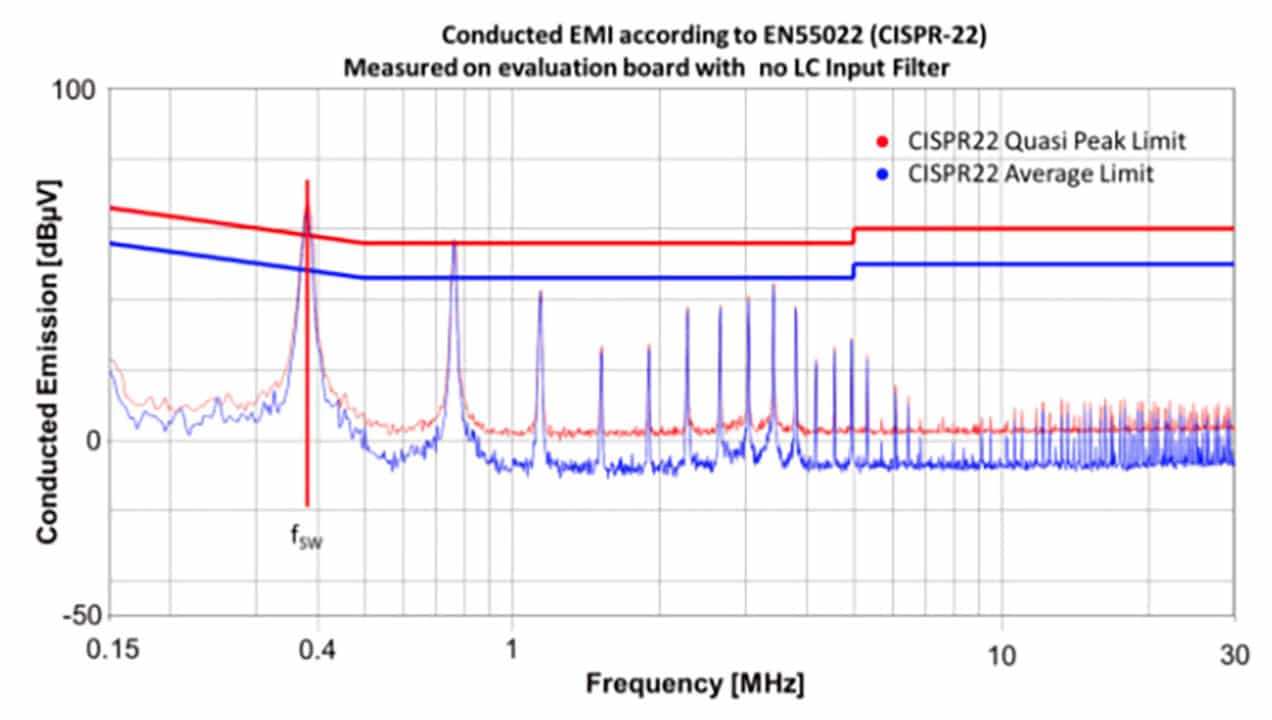

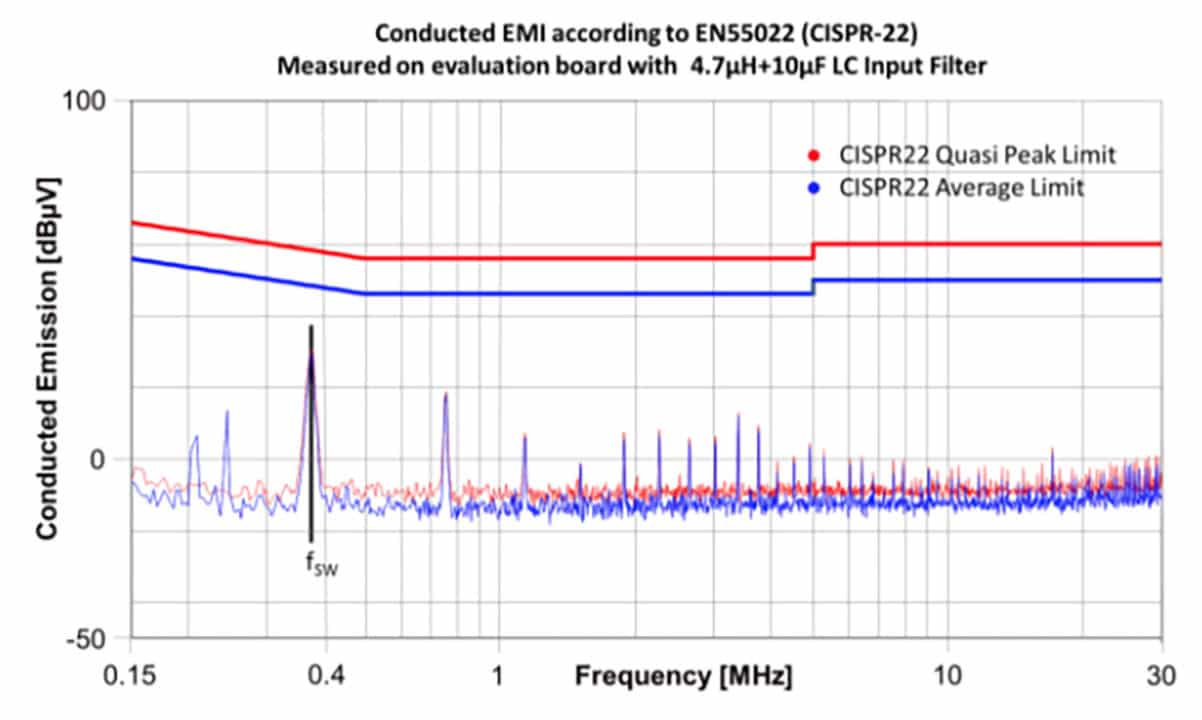

The decisive factor in the analysis of this type of noise emission, however, remains the measurement of noise voltage as can be per-formed in an EMC laboratory. Figure 12 shows the result of a noise voltage measurement without an input filter.

This power module operates at a clock frequency of 370 kHz. In the interference spectrum, the highest amplitude (red peak: 68 dBμV) can be measured at this frequency. The amplitude density of the noise voltage drops at a rate of approx. 40 dB/decade, meaning that no significant interference level can be seen above the 15th harmonic. Nevertheless, it is only above the 9th harmonic that the interference level is more than 10 dB below the limit for the average detector (dark blue line).

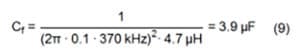

Equation (3) from Section 3 can now be used to calculate a suitable LC input filter. Due to the relatively low switching frequency, an inductor with a low SRF and an inductance of 4.7 μH is selected and the filter capacitance is calculated.

(9)

(9)

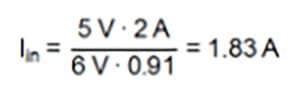

The selected filter capacitor is the one with a little higher capacitance of 10 μF. The maximum input current is calculated using equation (8) from Section 3.

This calculation requires the efficiency of the evaluation board, which is determined by measurement and in this case has a value of 91%

(10)

(10)

On the basis of the calculations of the filter inductance and input current, it is now possible to select an appropriate inductor. Picked for the purpose is an unshielded inductor from the Würth Elektronik PD2 series, size 5820. Figure 13 shows the result of the noise voltage measurement with the matched filter.

The interference level measured at the 370 kHz switching frequency has a value of 30 dBμV. The levels of all harmonics are lower than 20 dBμV and are thus sufficiently attenuated. The average level at 370 kHz corresponds to the peak level and is 18 dB lower than the average limit of 47 dBμV. In measuring such conducted interferences in the practical context, a signal-to-noise ratio of this dimension is entirely sufficient in order to confirm the conformity of this measurement.

The purpose of the measurement of the noise voltage is to demonstrate the usefulness of an analysis of the interference potential in the time domain; though an analysis in the frequency domain is still indispensable.

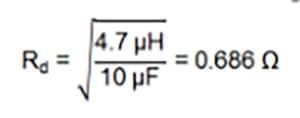

Finally, the equations from Section 3 can be used to calculate an attenuating resistance.

(11)

(11)

The higher the value of the attenuation resistance, the higher the attenuation of the filter resonance. In this case, the next higher resistance of the E12 series of 1 Ω can be selected.

A value of 47 μF is selected for the attenuation capacitor. This may be, for example, a Würth Elektronik eiCap ceramic capacitor of the WCAP-CSGP series.

MEASURING ACCORDING TO IEC CISPR 22

The above measurements were performed according to the IEC CISPR16-2-1 standard, as described in Section 8. The use of a LISN enabled the asymmetric voltage to be decoupled and equated to the asymmetric (common-mode) voltage, which was then compared to the limit, taken from the IEC CISPR 22 standard for devices for private and commercial use (Class B). For power-supply components – and this includes all types of switching controllers – there is no directly applicable EMC standard. The entire application in which the switching controller is used must be assigned to a specific category of devices and then tested according to the corresponding standard applicable for the product or product family. In this case, the product-family standard IEC CISPR 22 for IT installations was taken only with reference to the limits, which are also given in the IEC 61000-6-3 generic standard. The generic standards can be used in cases for which there is no specific standard for the device in question.

SUMMARY

Irrespective of the size of the AC component involved, an input filter is today as ever a requisite factor for a successful EMC validation of a switching controller. Simple-to-apply equations can be used to calculate such an input filter on an individual basis. Taking the impedances of the filter and the switching controller into account in the equations, this enables oscillations to be avoided and also ensures the control stability of the switching controller itself. A targeted selection of the filter components lays the foundations for an optimal design of the filter. Equipped with an appropriate degree of technical skill in EMC testing methods, the hardware developer can design his switch purposefully and, wherever necessary, make any adjustments to the filter himself.