As more consumer and commercial products are introduced with High-Definition Multimedia Interface (HDMI) cable connections, the resulting EMI issues related to HDMI cable emissions have continued to be problematic for product designers and EMC engineers. It is very common to have one, or more, added HDMI cables cause a product to fail the radiated emissions (RE) test.

The reason EMI has reared up is that many brands of HDMI cables have poor cable shield bonds to the connector back shell. Unfortunately, it’s not possible to simply purchase well-known cable brands and be assured of passing RE.

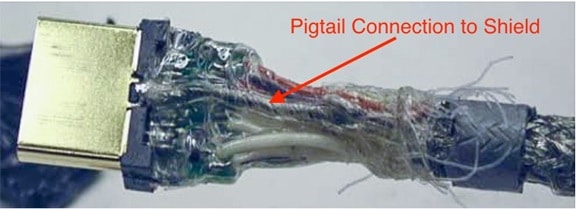

It’s not uncommon for the shield to be tied to the connector back shell with a one-inch, or longer, pigtail connection. The problem has been with the original HDMI standard, developed by the HDMI Forum Technical Working Group. Unfortunately, the standard never completely addressed the best way to terminate the cable shield – that is, what we call in the business, a “360-degree” bond, where the shield is bonded in multiple places (ideally, all around the back shell) directly to the connector back shell (ground).

At high frequencies, pigtails can become highly inductive. For example, a one-inch pigtail (about 20 nH of inductance) can appear as a12-Ohm impedance. As the frequency increases, the impedance also increases. As the impedance increases, the cable shield essentially becomes “disconnected” from the connector ground and the result is cable emissions.

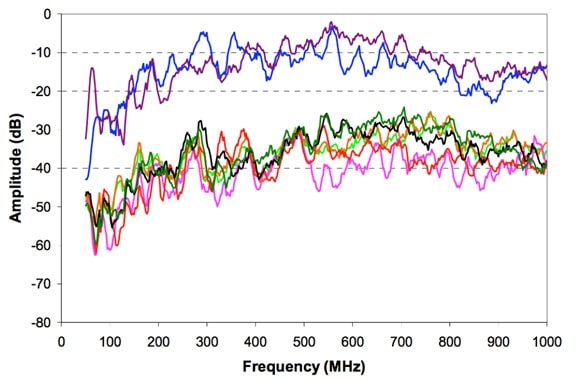

This issue has been dogging EMC engineers and compliance test labs for years. In 2008, Dana Bergey and Nathan Altland, both of FCI, authored a paper at DesignCON, entitled “EMI Shielding of Cable Assemblies”, where they tested a number of cables for their EMI emissions properties when driven by a swept RF source. The cables were tested for emissions in a conventional mode-stirred chamber.

Looking at just the HDMI results, eight cables were tested and two of them had emissions some 20 dB higher than the other six. Dissecting these cables, it quickly became apparent as to the reason – and that was the pigtail issue as noted above. See Figure 1.

I recently contacted Brad Bramy, HDMI Licensing Administrator, to determine whether the working group was aware of the issue and whether the current standards development would be resolving this through a more rigorous EMI-worthy assembly procedure. He passed my questions on to the working group. Here was the official reply:

- What exactly does the current HDMI specification say about this ground connection?

- The HDMI 1.4b specification governs current cable specifications, which were developed by the HDMI Founders. The Forum is not authorized to comment on the HDMI 1.4b specification or its content. HDMI LA works directly with the Founders and will be the best resource for you to get these questions answered.

- Does the newer version 2.1 spec address this better?

- HDMI 2.1 does introduce a new cable with improved overall performance (The current working marketing name is the 48G HDMI Cable). However, since the specification remains under final development, the Forum cannot yet comment on specific details.

- Is the working group aware of this problem and are there any plans to remedy this issue?

- The HDMI Forum Technical Working Group is aware of concerns about the current cable specifications. However, since the specification remains under final development, the Forum cannot yet comment on specific details.

While I’m encouraged that the working group is aware of the concern, time will tell whether future releases of the standard will address this issue. Let’s hope so! In the meantime, you’ll need to secure a range of high-quality HDMI cables and try them one at a time to find the best one to use for EMI testing – not an ideal solution.

References

- Bergey and Altland, EMI Shielding of Cable Assemblies, DesignCON 2008, http://www.magazines007.com/pdf/DC08_Dana_Bergey.pdf.

- HDMI Forum Technical Working Group, http://www.hdmi.org.