Introduction

Some 10-15 years ago this topic was irrelevant for the civil sector, and the issue of protection of electrical and electronic equipment from high altitude electromagnetic pulse (HEMP) solely belonged to military specialists. Today, much of the mass media discusses HEMP danger for civil infrastructure at the global level in all possible ways; and thus, this topic has become very relevant. In 2019, President Donald Trump even signed a special directive on the protection of the country’s infrastructure from HEMP.

On the one hand, the attention of the mass media to this topic inspires the hope that managers responsible for the core branches of infrastructure, (e.g. the electrical power industry, water supply, and communication) will take note of this issue and start addressing it eventually. On the other hand, people writing the articles in the media have actually no idea about the technical issues of HEMP, and also disregard this narrow field. Nevertheless, they often disseminate myths, which divert people’s attention and complicate problem solving.

Some other myths, let us call them “technical myths,” are also disseminated by some technical specialists and military men pursuing certain specific ulterior motives, sometimes far away from seeking the truth.

Another group that benefits from myths dissemination includes dozens of public and private U.S. companies dealing with HEMP issues and receiving generous funding from the state budget. These companies are interested in keeping the HEMP issue “afloat” as long as possible, and thus, their representatives have a temper tantrum when they hear about cheap and efficient technical solutions.

The reality of the current problem can be compared with a patchwork canvas of reality in the background of widely spread mythology.

The aim of this article is to review and criticize some common myths and provide those interested with a brief explanation and references suggesting a detailed description of this specific problem.

- The topic is classified and should not be discussed in the open media.

This myth is usually disseminated by military specialists who deal with this technical field. The aim is to prevent the publishing of this information, resulting in the possibility of the responsible officers being charged with continuous negligence, and entrusted with the responsibility to protect the civil sector, which is very undesirable for them.

Actually, the HEMP topic and its impact on electrical equipment and protection devices has been declassified for 50 years. During these years dozens of publically available reports and standards have been published on this topic, see an extensive list in [1]. Recently, a lot of articles discussing HEMP have appeared in the technical literature coupled with thick monographs, both in the Russian and English languages [2, 3].

- HEMP is a contrived problem as nobody will venture to be the first to use nuclear weapons in the modern world.

In order to generate a powerful electromagnetic pulse, the nuclear explosion should be blown at a very high altitude (more than 30 km) [4]. Therefore, all other affecting factors of this explosion, including the direct impact on people, will be virtually brought to zero. In fact, this high-altitude nuclear explosion is a “pure” weapon affecting only equipment, having no direct influence on people. This is what makes it so attractive for the military and politicians, and this is why the probability of its use is much higher compared to a conventional nuclear weapon (even a low-powerful tactical weapon). Considering the significant attractiveness of this “pure” weapon, many countries are on their way to developing so-called “Super-EMP,” i.e. nuclear ammunition featuring a much bigger proportion of emitted energy to generate the electromagnetic pulse compared to a common blast.

- HEMP prevention and protection activities belong to the sole responsibility of the military men rather than civil specialists.

As suggested by [5], the nuclear blast can be delivered to a 30 km altitude by relatively small-size missiles hidden in standard sea containers (Figure 1).

It is always possible to hide several containers with missiles among hundreds of ordinary containers sitting in seaports or resting on container carriers moored near large cities (Figure 2).

The flying time of these missiles to the target point is so negligent that an anti-ballistic missile system (ABM) will not have sufficient time to eliminate a threat. Thus, the threat of serious damage to core infrastructure cannot be eliminated by military assets. Concurrently, the responsibility for maintaining these facilities operate under the adverse effect and bringing them back to work in case of damage still rests with civil rather than military specialists, regardless of whether or not they are reluctant.

- It is impossible to protect the country’s civil infrastructure from HEMP with the available assets, and thus, no action is necessary.

The myths that it is impossible to protect the country’s civil infrastructure from HEMP with the available assets are disseminated by some military officials and politicians who have nothing to do with engineering. For example, even a well-informed Army General Michael V. Hayden, the former Director of National Security Agency (NSA) and former Director of Central Intelligence Agency (CIA) stated: “I don’t mean to be so flippant, but there really aren’t any solutions to THIS, so I would just leave it at that.” Indeed, there are a lot of simple and inexpensive technical solutions detailed in the technical literature, e.g. [2, 3]. I regret that high-ranking authorities use media to publish judgments based on their personal impressions and conclusions, and they do not even try to go into details of the issue they are not familiar with and study the opinion of the subject specialists. Moreover, some principals of academic institutions having all possible merits, but who are not engineering specialists, take courage to write negative reviews on articles that describe simple and affordable means of protection. The principals of military projects and R&D organizations specializing in this field are also very negative about discussing these issues in public media as they are afraid of responsibility, which can be delegated to them for ensuring the protection of core civil infrastructure.

- There is no data available to the civil technical staff that would enable the development of practical means to protect civil infrastructure.

This myth derives from the above as an attempt to substantiate inactivity in the field of infrastructure protection. Unfortunately, it is being disseminated by authorities responsible for the foundation of infrastructure, i.e., the power industry:

“Much of the available information is not specifically applied to electric utilities, making it very difficult for utilities and regulators to understand effective options for protecting energy infrastructure,” says Robert Manning, VP of the world-known Electric Power Research Institute’s (EPRI) department of power transmission and distribution.

He is being echoed by Mike Bryson, VP of Operations at Valley Forge, PA, who said, “I don’t think we have an illusion we will prevent it. That’s really the government’s job.”

The idea behind this myth is to avoid any efforts and any specific actions necessary to protect the electric power facilities and simultaneously relieve any responsibility for the current state of affairs. It will be sufficient to study the books in Figure 3 to make sure that the above-mentioned statements of the authorities are irrational and occurred either as a result of personal aberration or in an attempt to mislead the society.

- There are no standards describing the methods of HEMP protection of civil infrastructure, while military standards are not applicable to civil facilities.

I heard these statements from military specialists who used to work with military standards, having no idea about dozens of publically available (i.e. absolutely unclassified) standards (Figure 4) devoted to HEMP impact onto civil equipment, and methods of HEMP protection. The full list of these standards, as well as an extensive list of open reports (available for downloading from the internet) on how HEMP impacts the facilities of electrical power systems is provided in [1].

- Modern DPR systems intended for commercial and power industry use are well-protected from electromagnetic impact based on usual EMC standards and do not require any additional means of protection.

Indeed, commercial microprocessor-based monitoring and control devices, as well as digital protection relay (DPR), which are widely used in the power industry, should be protected from the impact of electromagnetic impacts occurring during their use. In other words, they should meet the ordinary requirements of electromagnetic compatibility (EMC). But there are two points here. First, DPR and other microprocessor-based devices used in the power industry do not always possess the required level of EMC and cannot always be considered duly protected from any electromagnetic interference affecting them during their use [6, 7]. Secondly, electromagnetic impacts affecting electrical equipment that occur upon high-altitude nuclear explosion may significantly differ in terms of their parameters from those suffering by this equipment in the course of normal operation. Thus, the means of protection used for ensuring EMC are not always sufficient to ensure HEMP protection.

- Earthing of electrical and electronic equipment is one of the main means of HEMP protection.

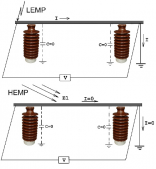

Indeed, according to all publications devoted to HEMP protection, earthing is deemed to be the major means of protection. The main idea of the majority of technical reports and standards is: the better the earthing, the more efficient the protection will be. But they always try to equalize HEMP and lightning EMP. In fact, these are absolutely different processes that have different physical implications and that impact equipment in different ways. To simplify, lightning, for example, is a local electric breakdown between two electrodes with opposite charges, i.e. a cloud and the ground. Whereas HEMP is a space charge distributed over the large area and caused by the flow of electrons moving from the Ionosphere to the Earth’s surface, as affected by its magnetic field, having nothing to do with the earth’s potential.

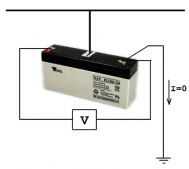

As mentioned in [8], the difference of potentials induced by HEMP between the ends of a long conductor and current flowing in it does not depend on availability or lack of earthing on one of the ends (as opposed to processes taking place upon lightning impact) (Figure 5). Similarly, the voltage between the poles of a battery insulated from the earth does not depend on availability or lack of earthing on one of its poles (Figure 6).

So, what is the role of earthing in this case? Unfortunately, even the leading specialists whom I asked could not answer this question and in fact, recognized the existence of the problem. This problem is not as harmless as it may seem, because the earthing system acts like a huge antenna absorbing energy from a large area and delivering it directly to sensitive electronic equipment. Thus, earthing can act as an additional interference source (from HEMP perspective) aggravating the situation rather than acting as HEMP protection.

- Electronic equipment can be protected by placing it into bags made of metalized plastic.

These recommendations can be found on various internet websites promoting these bags as a reliable means of protection. Simple calculations suggest that for 0.1–100 MHz frequency range (the range in which 96% of HEMP energy is emitted) the several micron metal layers provide poor interference damping, which is absolutely insufficient for electronic equipment protection (Figure 7).

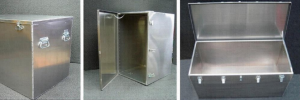

As mentioned in [9], electronic equipment should be placed in aluminum containers with a wall thickness of more than 3–4 mm to ensure the proper level of HEMP protection (Figure 8).

- Transition to fiber-optics communication line (FOCL) makes the protection of electronic equipment unnecessary.

This is one of the most common misconceptions. It is based on the fact that optic fiber is resistant to electromagnetic impact. Indeed, this is an unquestionable fact, but the resulting conclusion is erroneous. The problem is that the technology, which processes information coming to electronic equipment, is still based on the interaction of electrical signals rather than light streams. That is why optical signals coming to (and from) electronic equipment via FOCL will be converted into common electrical signals inside this equipment. In addition to optical cables, the equipment is connected via common electric cables (take at least the power cable!). Thus, this equipment is susceptible to HEMP in the same extent as any other device.

- Testing of electrical and electronic equipment on special HEMP simulating test benches is a must to develop the means of equipment protection.

Any armament system, which may be susceptible to HEMP, has been tested on special HEMP-simulating test benches during the engineering stage for decades as a type test.

When the influence of HEMP on civil equipment became evident (e.g. the cabinets with electronic equipment of supervision, automation and relay protection in the power industry, Figure 9), obviously the extensive experience accumulated during armament systems’ testing was transferred to this type of equipment as well. This includes testing of equipment on HEMP-simulating test benches.

Concurrently, nobody is concerned about an important difference between armament and civil equipment (e.g. those cabinets with electronic equipment). The internal electric wiring in the armament systems containing a lot of electronic parts (aircraft, missiles, tank weapons, radars, etc.) is performed using wire harness pre-fabricated on molds. This harness is exactly the same (just as employed electronic components and units) in all samples of the same type and possesses similar qualities and specifications from a HEMP impact perspective. Thus, the test results of one sample can be extrapolated on all other samples of the same type, and testing on HEMP-simulating test benches (as a type test) is important and informative.

As mentioned in [10], equipment used in the civil sector (e.g. the above-mentioned cabinets with electronic equipment of supervision, automation and relay protection) is different from (in terms of the identity of internal wiring and the components used in different samples of these cabinets) armament. The internal wiring of these cabinets is actually too far from optimum from the high-frequency impact perspective (HEMP). The difference in the wiring in various cabinets, types of electronic devices installed inside, and their placement inside the cabinets, makes the HEMP response of these appliances absolutely unpredictable. For example, [10] provides a specific example suggesting that even a 0.5-meter difference in the length of the mounting wire may result in a significantly different HEMP response of the circuit.

Due to the aforementioned reasons, the HEMP-response of each individual cabinet with electronic equipment placed on the test bench will be absolutely different. In other words, there is no “typical” cabinet design that could be tested with further extrapolation of the results to other cabinets.

There are other problems related to testing on HEMP-simulating test benches [11], e.g. availability of a grounded lower electrode of an antenna system in the most common types of simulators (Figure 10).

When this earthing is available, the additional earthing of the cabinet (in essence, connecting it to the lower electrode of an antenna system) will significantly distort the real picture of HEMP impact.

Considering the above-mentioned reasons, the costly tests of such type of civil devices on military HEMP-simulating test benches can be acknowledged unjustified and unreasonable [11].

- Successful tests of electronic devices (particularly DPR) as affected by low power radio emission from a directional antenna prove its HEMP resistance, and therefore, it is unnecessary to ensure additional protection.

Some manufacturers of electronic equipment “fool around” with this type of test (i.e. using low power radio emission from a directional antenna) in order to prove that their equipment is “the best” is not an issue for HEMP. In particular, there are publications supporting this idea from American companies, e.g. General Electric (GE) [12], Schweitzer Engineering Laboratories (SEL) [13, 14], etc.

Measuring the level of attenuation of electromagnetic emission in the certain frequency range provided by, for example, a cabinet, container, or protecting shield by means of a small low power source of radio emission and a directed antenna, represents an important method to prove the efficiency of these protection means and is widely used in practice. However, drawing conclusions about HEMP resistance of electronic equipment, connected with numerous types of other devices via multiple long cables in the real mode of operation, based on mere exposure to low power high-frequency electromagnetic emission, coming from a stand-alone appliance located on a test-bench, (what those hapless-investigators from SEL and GE did) (Figure 11) is nothing more than just profanation of the method.

The authors of [12] eventually agreed with my criticism and removed conclusions about HEMP resilience and misleading figures (though they kept them in the presentation file) from their publication.

A full report on mistakes and nonsense in [13, 14] is provided in [15].

- Available means of protection, e.g. HEMP filters for electronic equipment are too expensive and they are unlikely to be used for the civil sector.

Indeed, electromagnetic filters designed for HEMP protection are rather expensive and bulky. Even single-phase two-conductor filters (the simplest) designed for installation into DC or single-phase AC supply circuits featuring 3–10 A cost between $1,500 and $2,500 and weigh 10–15 kg with a length of 0.5 meters. The use of these filters in standard cabinets containing civil electronic equipment is really unacceptable.

Nevertheless, considering the above-mentioned limits of HEMP’s real frequency range, it becomes obvious that there is no need to use special HEMP filters designed for frequency ranges of up to 40 GHz for civil equipment. Our unpublished data suggest that some types of small and cheap ($20 to $30) EMC filters (among those numerous types available in the market intended to ensure the equipment’s EMC) feature really good specifications within the required frequency range. Considering the general strategy of protecting the power system’s electronic equipment [18], and the fact that electromagnetic filters represent just one of the “layers” in multi-layer protection, the problem may be solved by using specially selected types of small and cheap EMC filters instead of expensive HEMP filters.

- The problem of power transformers protection has not been solved yet because geomagnetically-induced currents limiters offered by some companies are very large and expensive for their practical use in civil power systems.

Power transformers may be damaged by geomagnetically-induced currents (GIC) entering the unit via the earthed neutral conductor. This current occurs under the impact of a so-called E3 component of HEMP and features very low frequency (fractions of Hertz) at dozens-hundreds amps amplitude. This current results in the transformer’s magnetic core saturation and consequently sharp reduction of its impedance and winding blowing. Renewal of a large power transformer is very complicated, time-consuming, and expensive; thus, the protection of transformers from HEMP is extremely important in the electrical power industry. Until recently, the market offered only one ready-made technical solution for practical use: GIC limiter for a transformer’s neutral conductor SolidGroundTM offered by ABB company [17, 18] (Figure 12). This is a large high-voltage unit, which costs about $300,000 and is very difficult to use in a large number of power system’s transformers due to its large size and high cost. Consequently, the problem of transformers’ protection was regarded as unsolved until now.

We offered a solution back in 2011. The idea behind the solution involved a short-term shutdown of the transformer by a regular circuit breaker upon a signal received from a small DC sensor placed on a flat cable earthing its neutral conductor (Fig. 12), with further automatic return to operation (circuit breaker reclosing) after a several-minute pause.

The article [19] provides a detailed description of digital relay protected from HEMP, which reacts to direct current (only!) in the transformer’s neutral conductor, and a device for its periodical testing developed by the author and suitable for batch production and use in power systems. Thus, the problem may be regarded as solved.

Conclusion

I hope that these critical comments regarding the myths around HEMP provided in this article, will clarify the ambiguity and really assist personnel involved in power systems operation to understand and correctly appreciate the problem.

References

[1] Gurevich V. EMP and Its Impact on Electrical Power System: Standards and Reports. – International Journal of Research and Innovation in Applied Science, 2016, Vol. 1, Issue VI, pp. 6 – 10.

[2] Gurevich V. The Electromagnetic Pulse of a High-Altitude Nuclear Explosion and the Protection of Electrical Equipment from It. – Moscow, Infra-Engineering, 2019. – 516 p. (Rus.)

[3] Gurevich V. Protecting Electrical Equipment. Good Practices for Preventing High Altitude Electromagnetic Pulse Impacts. – De Gruyter, Berlin, 2019. – 386 p.

[4] Gurevich V. A Complementary View of HEMP for Electrical Engineers. – International Journal of Electrical and Electronics Research, 2018, Vol. 6, Issue 2, pp. 76 – 89.

[5] Gurevich V. Intentional Electromagnetically Destructive Impacts – a Threat to the National Security of the Country. – Issues of Risk Analysis, 2016, Vol. 13, No. 5, pp. 44 – 51.

[6] High Frequency Switching Surge in Substation and its Effects on Operating of Digital Relays in Japan. – Reference C4-304-2006, CIGRE Study Committee C4, 2006.

[7] Matsumoto T., Kurosawa Y., Yamashita K., Tanaka T. Experience of Numerical Protective Relays Operating in an Environment with High-Frequency Switching Surge in Japan. – IEEE Transactions on Power Delivery, Vol. 21, No. 1, 2006, pp. 88 – 93.

[8] Gurevich V. Is the Electric Equipment Grounding the Basic Protection Means Against HEMP? – Military & Aerospace EMC Guide, Interference Technology, 2018.

[9] Gurevich V. Establishment of Inventory of Electronic Equipment Replacement Modules as a Way to Improve the Survivability of the Power System. – “International Journal of Electrical and Computer Engineering Systems”, 2015, Vol. 6, No. 2, pp. 33 – 37.

[10] Gurevich V. HEMP Protection of Electronic Equipment Located in Control Cabinets. – International Journal of Research Studies in Electrical and Electronics Engineering, 2019, Vol. 5, Issue 1, pp. 1 – 7.

[11] Gurevich V. The Problem of Testing HEMP Resilience of Electronic Equipment of Automation, Control and Relay Protection. – International Journal of Research Studies in Electrical and Electronics Engineering, 2019, Vol. 5, Issue 3, pp. 14 – 22.

[12] Mao R., Vardhan H., Adamiak M.., etc. Control House and Relay Design Considerations for EMP Resiliency. – Protective Relay Conference, Texas A&M, 2019 (http://prorelay.tamu.edu/wp-content/uploads/sites/3/2019/03/Control-House-Design-for-EMP-Final-R2.pdf).

[13] EMP Effects on Protection and Control Systems. – Schweitzer Engineering Laboratories, 2014.

[14] Minteer T., Mooney T., Artz S., Whitehead D. E. Understanding Design, Installation and Testing Methods That Promote Substation IED Resiliency for High-Altitude Electromagnetic Pulse Events. – 44th Annual Western Protective Relay Conference, Washington, October 17 – 19, IEEE.

[15] Gurevich V. Resilience of Digital Protective Relays to Electromagnetic Pulse (HEMP). – International Journal of Research and Scientific Innovations, 2017, vol. IV, issue XII.

[16] Gurevich V. HEMP Protection Strategy for Power System’s Electronic Equipment. – Interference Technology, 2019, November 6.

[17] SolidGround™ neutral blocker is the most effective and economical solution to protect the electric power grid from stray DC, Solar Storms (GMD) and Nuclear EMP E3 – http://www.emprimus.com/solidground

[18] SolidGroundTM Grid Stability System Geomagnetic Storm Induced Currents (GIC) and Electromagnetic Pulse (EMP) E3 Protection. – ABB Inc. High Voltage Products, 2012.

[19] Gurevich V. Protection of a Power Transformers from High Altitude Electromagnetic Pulse. – International Journal of Research Studies in Electrical and Electronics Engineering, 2020, Vol. 6, Issue 1, pp. 17 – 24.